Aluminum possesses excellent physical properties, processing performance, surface treatment performance, and a rich variety of surface treatment processes. They are the perfect substitute for plastics, stainless steel, ceramics, and ordinary alloys in the field of 3C digital electronics and are increasingly being used in the 3C electronics sector.

3C Electronic Product Concept

- Computer

- Communication:Mobile phones, communication equipment

- Consumer Electronics:TV sets, refrigerators, cameras, audio equipment

Characteristics and Advantages of Aluminum

Low Density, High Strength, Lightweight Advantages

| Material | Grade | Density (tons/m³) | Tensile Strength (MPa) | Yield Strength (MPa) | Specific Strength | Hardness (HV) |

| Aluminum | 6061 T6 | 2.7 | 310 | 276 | 115 | 107 |

| Stainless Steel | SUS304 | 8.03 | 645 | 285 | 80 | 200 |

| Titanium | 6AL4V | 4.54 | 895 | 825 | 197 | 349 |

| Magnesium | AZ91D | 1.81 | 230 | 160 | 127 | 72 |

| Glass | GORILLA | 2.44 | - | 863 | - | 550 |

| Ceramic | ZrO2 | 6 | - | 1000 | - | 1200 |

Low Cost, Cost-Effective Advantage

| Material | Aluminum | Stainless Steel | Titanium | Magnesium | Glass | Ceramic |

| Ingot PriceCNY/ton | 20400 | 14500 | 45000 | 17500 | - | - |

Note: prices are from SMM on December 13, 2024

High Thermal Conductivity, Fast Heat Dissipation

| Material | Aluminum 6061T6 | Stainless Steel SUS304 | Titanium 6AL4V | Magnesium AZ91D | Glass GORILLA | Ceramic ZrO2 |

| Conductivity(W/(m⋅K)) | 167 | 16.3 | 7.1 | 78 | 1.0 | 3.0 |

Excellent Processing Performance

| Material | Aluminum | Stainless Steel | Titanium | Magnesium | Glass | Ceramic |

| Description | Good forming performance, can be welded, riveted, bonded, nano-injection molding, good CNC processing performance | Good forming performance, but CNC processing is prone to tool adhesion, time-consuming, and high tool consumption | Prone to tool adhesion in CNC processing, time-consuming, and high tool consumption | Poor forming performance | Brittle material, not easy to process | Brittle material, not easy to process |

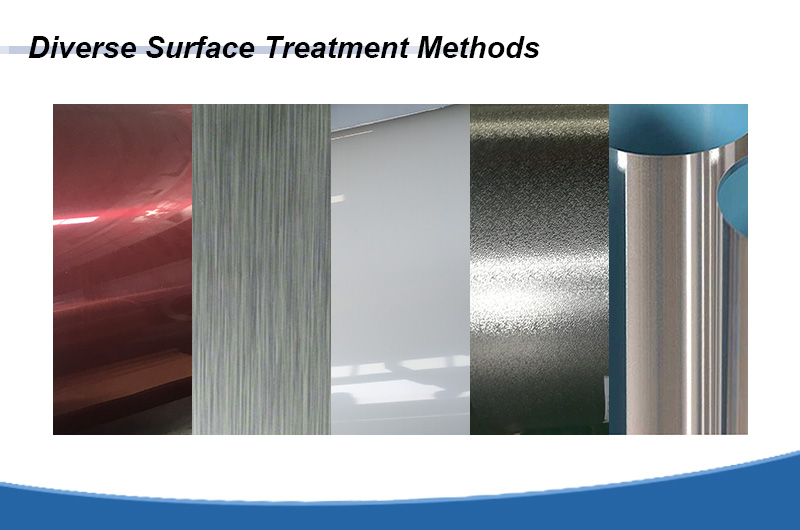

Diverse Surface Treatment Methods, Aesthetic Appearance

- Anodizing:Hard anodizing, mirror anodizing, gradient anodizing

- Coating:PE, PVDF, epoxy clear coat

- Brushing:Brushed gold, brushed silver

- Mirror Finish:Mirror gold, mirror silver

- Stucco:Orange peel, insect pattern

Aluminum Sheets Coils and Strips for 3C Electronics

Types of Aluminum Sheets

- Alloys:1000, 3000, 5000, 6000, 7000, 8000 series

- Thickness Range:0.15mm-10.0mm

- Length Range:Customizable

Performance:

| Alloy | Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) |

| 5052 | H32 | 245 | 185 | 12 | 78 |

| 5252 | H32 | 235 | 180 | 12 | 75 |

| 5182 | H34 | 338 | 283 | 10 | 105 |

| 6063 | T6 | 260 | 230 | 12 | 83 |

| 6061 | T6 | 310 | 276 | 12 | 95 |

| 7075 | T6 | 572 | 503 | 11 | 180 |

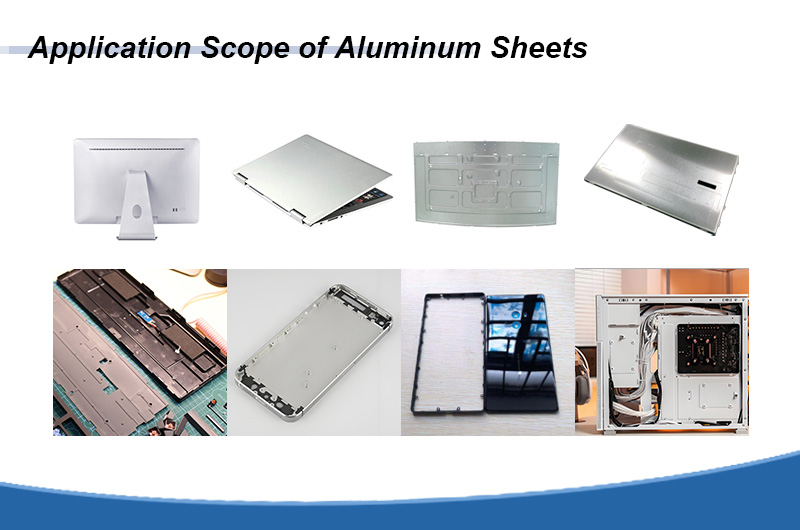

Application Scope of Aluminum Sheets

Exterior components of 3C electronic products, such as computer and mobile phone shells, cases, etc.

Structural components of 3C electronic products, such as keyboards, mobile phone frames, mid-panels, LED back panels, etc.

Processing Techniques for Aluminum Sheets

Mobile Phone Shells, Frames, and Mid-Frames

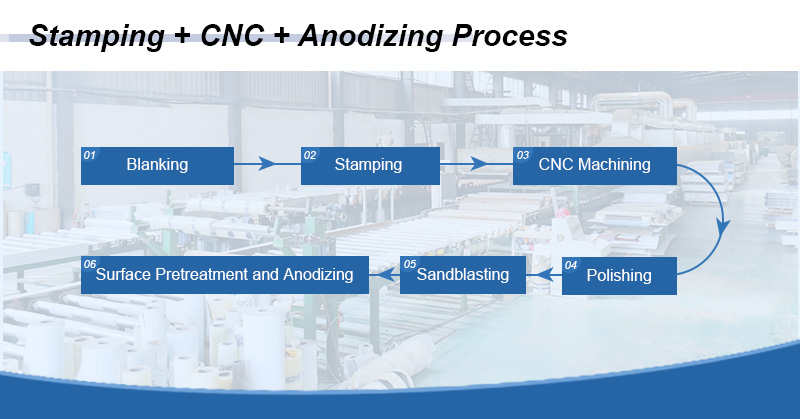

Stamping + CNC + Anodizing Process:

- Blanking

- Stamping

- CNC Machining

- Polishing

- Sandblasting

- Surface Pretreatment and Anodizing

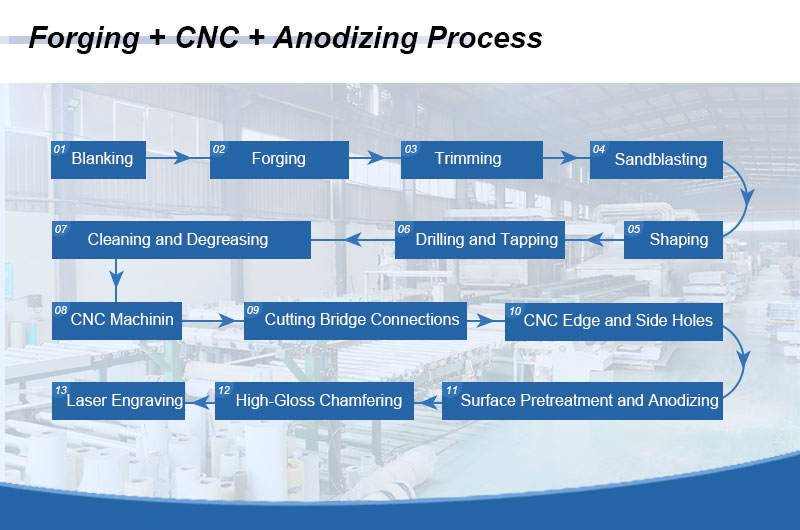

Forging + CNC + Anodizing Process:

- Blanking

- Forging

- Trimming

- Sandblasting

- Shaping

- Drilling and Tapping

- Cleaning and Degreasing

- CNC Machining

- Cutting Bridge Connections

- CNC Edge and Side Holes

- Surface Pretreatment and Anodizing

- High-Gloss Chamfering

- Laser Engraving

Mobile Phone Mid-Frames

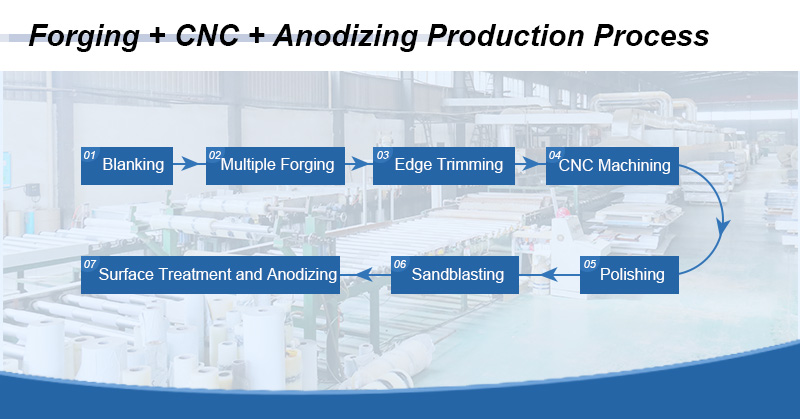

Forging + CNC + Anodizing Production Process:

- Blanking

- Multiple Forging

- Edge Trimming

- CNC Machining

- Polishing

- Sandblasting

- Surface Treatment and Anodizing

Aluminum Profiles for 3C Electronics

Types of Aluminum Profiles

- Alloys:6000, 7000 series alloys

- Thickness Range:7-10mm

Performance:

| Alloy | Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) |

| 6063 | T6 | 260 | 230 | 12 | 83 |

| 6061 | T6 | 310 | 276 | 12 | 95 |

| 7075 | T6 | 572 | 503 | 11 | 180 |

Application Scope of Aluminum Profiles

Shells of 3C electronic products, such as integrated frames or shells of mobile phones and laptops.

Structural components of 3C electronic products, such as mobile phone frames, computer frames, etc.

Processing Techniques for Aluminum Profiles

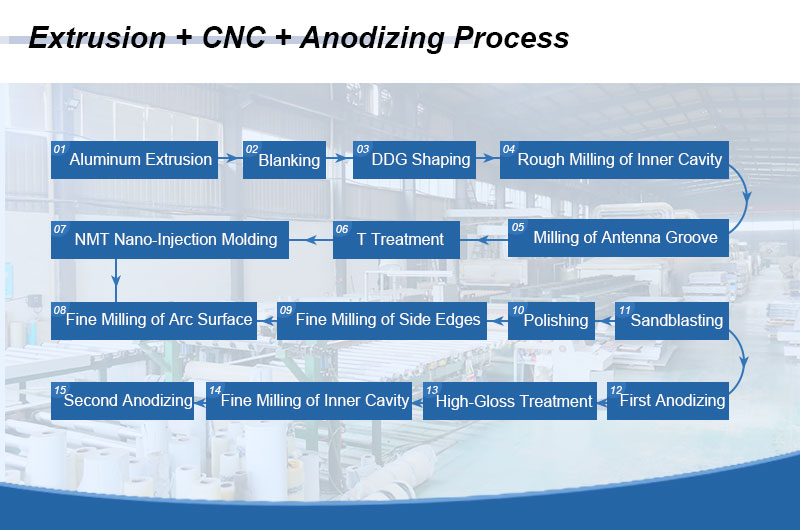

Extrusion + CNC + Anodizing Process:

- Aluminum Extrusion

- Blanking

- DDG Shaping

- Rough Milling of Inner Cavity

- Milling of Antenna Groove

- T Treatment

- NMT Nano-Injection Molding

- Fine Milling of Arc Surface

- Fine Milling of Side Edges

- Polishing

- Sandblasting

- First Anodizing

- High-Gloss Treatment

- Fine Milling of Inner Cavity

- Second Anodizing

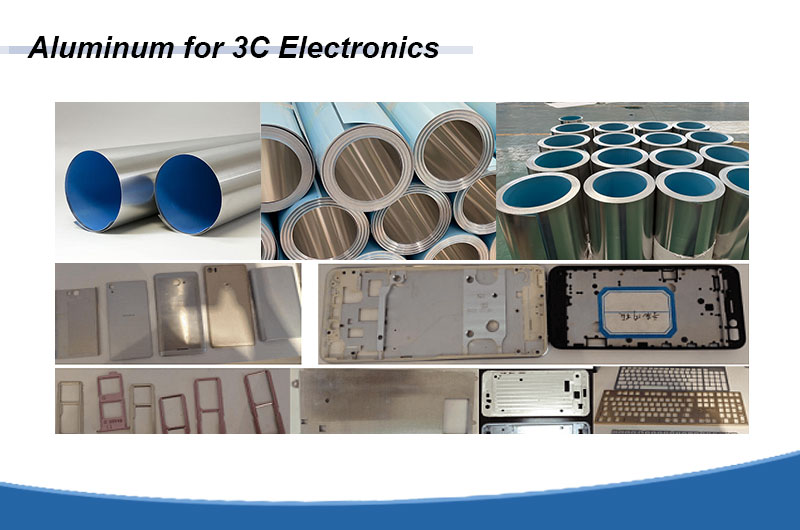

Die-Cast Aluminum for 3C Electronics

Types of Die-Cast Aluminum

- Alloys:A1-Si, AI-Mg, AL-Si-Cu, AI-Si-Mg, AI-Si-Cu-Mg, A-Zn, etc.

- For Anodizing:ADC5, ADC6, DM3, DM2, DM6

Performance:

| Property | DM3 | DM6 | ADC6 | ADC12 |

| Tensile Strength (N/mm²) | 118 | 235 | 255 | 323 |

| Yield Strength (N/mm²) | 49 | 137 | 118 | 179 |

| Elongation (%) | 28 | 7 | 15 | 4 |

| Brinell Hardness (HB) | 30 | 58 | 60 | 90 |

| Liquidus Temperature (℃) | 657 | 652 | 641 | 593 |

| Solidus Temperature (℃) | 652 | 643 | 599 | 538 |

| Density (Kg/m³) | 2.72 | 2.75 | 2.65 | 2.72 |

Application Scope of Die-Cast Aluminum

Integrated frames and shells of mobile phones and laptops.

Structural components of 3C electronic products, such as mid-panels, frames, accessories, etc.

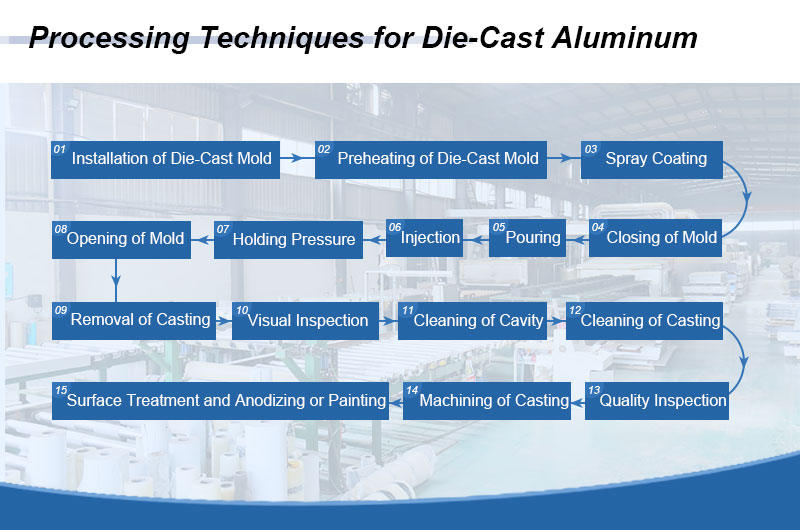

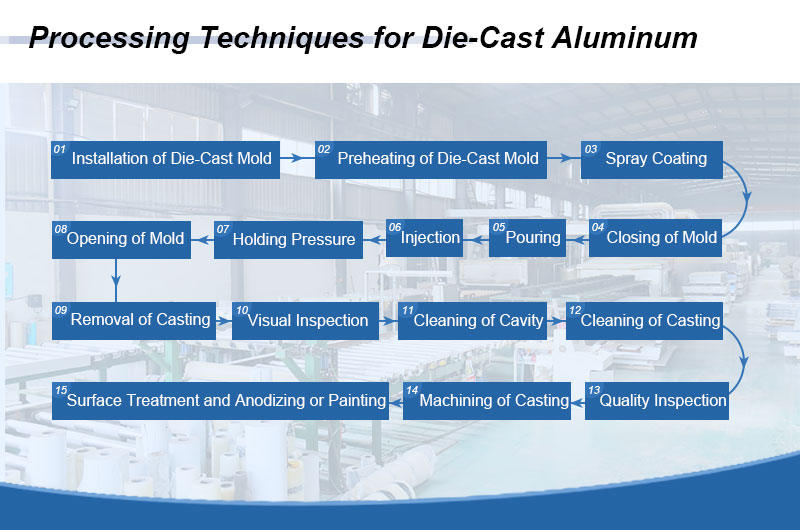

Processing Techniques for Die-Cast Aluminum:

- Installation of Die-Cast Mold

- Preheating of Die-Cast Mold

- Spray Coating

- Closing of Mold

- Pouring

- Injection

- Holding Pressure

- Opening of Mold

- Removal of Casting

- Visual Inspection

- Cleaning of Cavity

- Cleaning of Casting

- Quality Inspection

- Machining of Casting

- Surface Treatment and Anodizing or Painting

Comparison of Aluminum Processing Techniques

Example:Processing Techniques for Mobile Phone Shells/Frames

| Process | Strength | Surface Treatment Method | Material | CNC Time | Cost |

| Full CNC Profile | High | Anodizing | Much | Much | High |

| Forged Sheet | High | Anodizing | Little | Little | Medium |

| Stamped Sheet | Medium | Anodizing | Very Little | Little | Low |

| Die-Cast | Medium-Low | Painting | Little | Little | Low |

Choose the Right Processing Technique Based on Product Positioning and Design Features

Typical 3C Structural Components

LED Back Panels

| Alloy Grade | Supply Condition | Thickness (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Application Scope | Advantages |

| 1050 | H14/24 | 0.3~0.6 | 90-125 | 95~130 | Small-sized TVs | Low cost, good formability, excellent panel quality |

| 5052 | H32 | 0.6~1.0 | 160~190 | 215~245 | Back panels for TVs around 24 inches | High strength, good formability, excellent panel quality |

| 5052 | O | 1.0~2.0 | 80~130 | 180~210 | Back panels for TVs larger than 32 inches | High strength, good formability, excellent panel quality |

| 3104 | O/H111 | 1.0~1.5 | 70~100 | 170~190 | Back panels for TVs larger than 32 inches | High strength, good formability, excellent panel quality |

Internal Structural Components

| Alloy Grade | Supply Condition | Thickness (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Application Scope | Advantages |

| 5052 | H32 | 0.3~3.0 | 160~190 | 215~260 | General structural components | Excellent formability, moderate strength |

| 5052 | O | 0.3~3.0 | 80~130 | 180~215 | Products with deep drawing requirements | Excellent formability, moderate strength |

| 5052 | H32/H34 | 0.15~0.3 | 160~190 | 210~260 | Qingguang plates (possibly a specific product or brand) | Good panel quality, good formability, high strength, can replace stainless steel plates |

| 5182 | O | 0.3~2.0 | >140 | >280 | Products with deep drawing requirements and high strength demands | High strength, good formability |

| 5182 | H34 | 0.3~2.0 | >240 | >330 | Mobile phone mid-frames | High strength, good formability |

| 5B59 | H34 | 0.3~0.5 | >290 | >370 | Products with deep drawing requirements and high strength demands | High strength, good elongation, strong corrosion resistance, fast heat dissipation |

Anodized Aluminum for 3C Electronics

| Alloy Grade | Typical Condition | Thickness (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Application Scope | Advantages |

| 1050 | H14/24 | 0.3~3.0 | 90-125 | 95~130 | Air conditioning, microwave shells | Low cost, bright surface after anodizing |

| 5005 | H14/24 | 0.3~2.0 | 125~165 | 145~185 | Ceilings of large stations, curtain walls, computer cases | Uniform color, good corrosion resistance |

| 5052 | H32/H34 | 0.3~3.0 | 160~190/210~240 | 215~240/230~260 | Laptop shells, camera apertures | High strength, good processability |

| 5252 | H32/H34/H36/H38 | 0.5~3.0 | 160~230 | 210~270 | Mobile phones, laptops, computers, speaker shells | High strength, good formability, transparent anodizing film, no material marks |

| 6530 | 0.6~3.0 | >235 | >290 | Mobile phone shells, card trays | High strength, good anodizing effect | |

| 7550 | 2~10 | >340 | >430 | Mobile phone mid-frames | Very high strength, good anodizing effect |

Why Choose Us?

Worthwill is a leading enterprise in the domestic aluminum sheet and strip industry. Our industrialized 3C products have been recognized and widely used by mobile phone companies such as Huawei, OPPO, VIVO, Xiaomi, as well as computer companies like Lenovo, HP, and ASUS.

Exterior Components:High surface requirement anodized sheet and strip materials, such as mobile phone shells, computer shells, mobile phone frames, cases, etc.

Inner Components:Such as LED aluminum back panels, keyboard materials, mobile phone mid-panels, back panels, card trays, etc.