Aluminum fan blades are lightweight and corrosion-resistant, and are widely used in environments that require high efficiency and durability. When they rotate, they inhale cold air and expel hot air, achieving airflow and heat dissipation. They are mainly used for temperature control in industrial ventilation, HVAC and automotive cooling systems.

Worthwill's industrial ceiling fan blades are made of 5052 aluminum sheet which are meet the ASTM B209 standard.

Common aluminum sheets for aluminum fan blades

1000 Series

1000 series aluminum are almost pure aluminum with a small amount of impurities. It has good formability and the best corrosion resistance among aluminum alloys, but its strength is low and it is usually not used to manufacture fan blades that need to withstand greater stress. In some small or decorative fans with special requirements for weight and thermal conductivity, 1 series aluminum alloys may be used.

3000 Series

3000 series is an aluminum-manganese alloy with good corrosion resistance and weldability. And it is suitable for manufacturing some fan part that do not require extremely high strength but require good corrosion resistance, such as some types of fan housings or brackets.

5000 Series

Because of the addition of magnesium, 5 series aluminum alloy has higher strength, good weldability and corrosion resistance. These characteristics make 5 series aluminum alloy very suitable for fan blade materials, especially in those working environments with harsh conditions (such as high humidity or environments with chemical corrosion risks). In addition, 5 series aluminum alloy also has good fatigue strength, which is very important for fan blades that run at high speed for a long time.

Aluminum fan blade VS plastic fan blades

The following aspects will be analyzed:

Durability: Aluminum fans are more durable than plastic blades and can withstand longer and more frequent use without breaking or deforming easily.

Stability: Aluminum blades are more stable than plastic blades, have higher strength, and have a more uniform rotation speed. Especially suitable for high-power fans, aluminum blades can provide stronger and more stable airflow. Long-term use of plastic fan blades may cause deformation of the plastic fan blades or weakening of the wind force.

Heat dissipation: Aluminum is a good thermal conductive material. Aluminum fan blades have better heat dissipation performance and can dissipate heat faster, which helps the fan dissipate heat more efficiently. This helps to extend the service life of the motor.

Aesthetics: Aluminum fan blades have a more refined appearance, better texture, and better match with interior decoration.

Noise: The fan noise of aluminum fan blades is relatively small because metal is not easy to resonate, making the fan run more quietly.

Wind power: Aluminum fan blades have a relatively large air volume and strong wind force, which can quickly dissipate heat and are suitable for large areas of space. Plastic fan blades are weak and have weaker wind force.

To sum up, aluminum fan blades are superior to plastic fan blades in terms of durability, stability, heat dissipation performance, aesthetics, noise control and wind power, and are suitable for use in occasions where higher fan performance requirements are required.

5052 Aluminum sheet for aluminum fan blades

Product specifications

| Alloy | 5052 |

| Temper | H12, H22, H32, H38, H112 |

| Thickness | 1.5-3mm |

| Width | 1000-2000mm |

| Length | 3000-6000mm |

| Surface Treatment | Double-sided polished or Single-sided polished |

| Color | Silver or Customized |

| Package | Strapped packaging or Customized |

Chemical composition

| Element | Composition(%) |

| AI | Remainder |

| Mg | 2.2-2.8 |

| Si | 0-0.25 |

| Fe | 0-0.4 |

| Cu | 0-0.1 |

| Cr | 0.15-0.35 |

| Zn | 0-0.1 |

| Mn | 0-0.1 |

| Other(Total) | 0-0.15 |

| Other(each) | 0-0.05 |

Performance parameters

| Temper | Thickness/mm | Tensile strength/Mpa | Non-proportional tensile strength/ Mpa | Elongation/% |

| H12 | >0.20-0.50 | 210-280 | 180 | 4 |

| >0.50-1.50 | 5 | |||

| >1.50-3.00 | 5 | |||

| >3.00-6.00 | 8 | |||

| H22,H32 | >0.20-0.50 | 210-260 | 130 | 5 |

| >0.50-1.50 | 5 | |||

| >1.50-3.00 | 7 | |||

| >3.00-6.00 | 10 | |||

| H38 | >0.20-0.50 | 270 | 210 | 3 |

| >0.50-1.50 | 3 | |||

| >1.50-3.00 | 4 | |||

| H112 | >6.00-12.50 | 190 | 80 | 7 |

| >12.50-40.00 | 170 | 70 | - | |

| >40.00-80.00 | 170 | 70 | - |

Application

Construction machinery

Generators, pesticide sprayers, axial fans and other engineering machinery.

Wind power

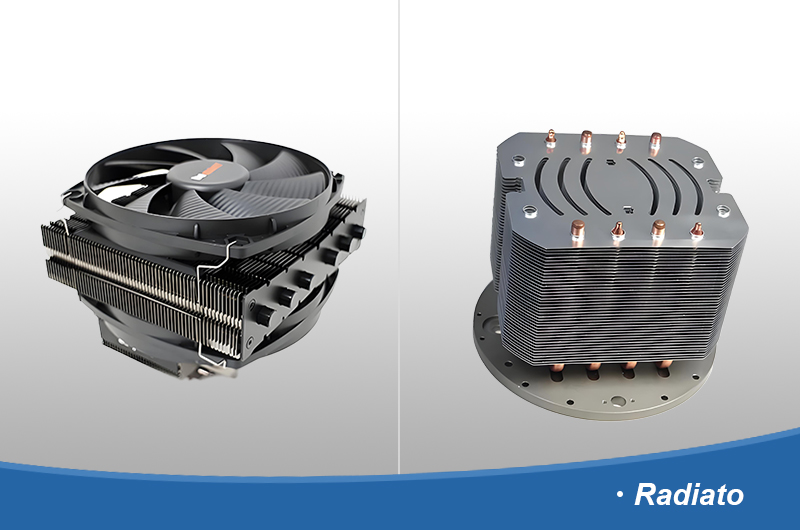

Radiator

Cooling tower

Package

Usually, carton packaging is adopted to pack the fan blades and parts in different areas to protect the fan blade surface from scratches and deformation. Buffer air cushions or foam will also be placed inside the box according to customer requirements.

Contact us

Henan Worthwill Industry Co., Ltd has been actively engaged in the aluminum alloy products industry for more than 10 years, and each employee of the company has more than 5 years of international trade experience. It is worth mentioning that we have our own factory to meet the personalized needs of customers. The main products include aluminum strips, aluminum sheets/coils, color-coated aluminum coils, aluminum foils, etc. Mainly exported to Southeast Asia, North Africa and the Middle East markets, such as South Korea, Vietnam, Thailand, Myanmar, the Philippines, Singapore, Jordan, Dubai and Kuwait, etc.