In the modern offset printing industry, aluminum plates are the core basic materials of PS plates (pre-painted photosensitive plates) and CTP plates (computer-to-plate), Aluminum offset printing plates usually include PS plates and CTP plates.

Aluminum plates are an ideal choice for offset printing plates due their low density, high strength, easy forming, good hydrophilicity, and high stability. Its high purity and excellent surface treatment capabilities can meet the needs of high-precision printing and ensure high-quality printing effects.

PS plates: The mainstay of traditional printing

PS plates are a plate material that forms a printed image by coating the surface of aluminum plates with photosensitive resin, exposing and chemically treating it. They are widely used in newspapers, magazines, books, and commercial printing.

Types of PS plates

- Photopolymerization: Using a negative original plate, the image part is hardened by light, and the non-image part is removed.

- Photodecomposition: Using a positive original plate, the non-image part is decomposed by light, and the image part is retained.

Surface coating

-

Photosensitive layer: Sensitive to specific wavelengths of light, forming image areas and non-image areas.

- Photopolymerization type: polymerization occurs when exposed to light, forming a stable image.

- Photodecomposition type: decomposes when exposed to light, making it easier to wash away the non-image part.

- Hydrophilic layer: usually anodized aluminum layer, with good hydrophilicity and wear resistance.

- Oleophilic layer: composed of diazo photosensitive resin, with a thickness of about 3μm, with oleophilic and hydrophobic properties.

- Grit structure: formed by electrolytic roughening process, so that the plate surface has ideal dot reproduction conditions and good hydrophilicity.

Features of PS plates:

- High resolution and dot reproduction: high-precision dot reproduction can be achieved tensure image details and layering.

- High printability: The printability can reach hundreds of thousands of prints, suitable for long-run printing, and has good wear resistance and acid resistance.

- Environmental protection: Modern PS plates reduces the discharge of chemical waste liquid and meets environmental protection requirements.

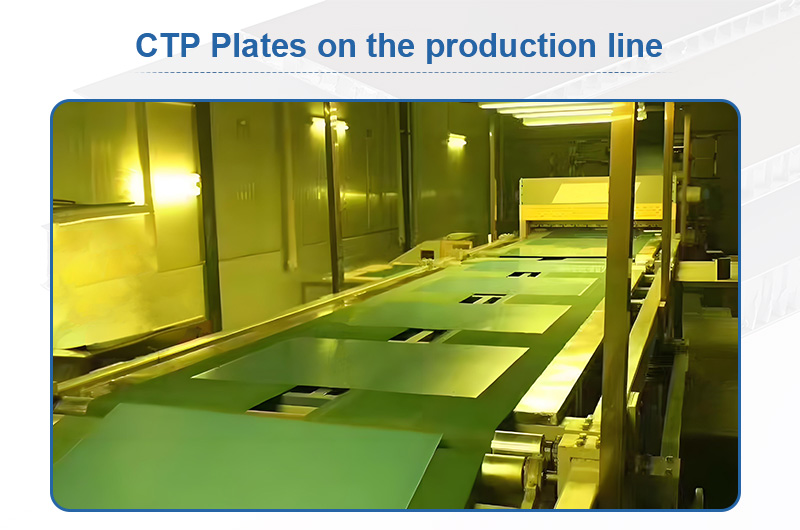

CTP plates: The future of digital printing

CTP plates are a major innovation in the offset printing industry. It directly transmits image data taluminum plates through computers, eliminating the traditional film link and significantly improving platemaking efficiency and printing quality.

Features

- High-precision imaging: laser exposure achieves high-resolution image reproduction and more precise dot control.

- Environmental protection: Reduce chemical treatment and waste liquid discharge, support waterless printing and chemical-free plate materials.

- Fast platemaking: Suitable for short-run printing, digital process quickly responds tmarket changes and shortens production cycle.

- Good water-ink balance performance: Optimized surface treatment reduces ink waste and improves printing quality.

Surface coating types

- Thermosensitive coating: suitable for infrared laser exposure, low sensitivity to natural light, can be operated under bright room conditions.

- Silver salt emulsion layer: has high sensitivity and is suitable for a variety of laser systems.

- Photopolymerization coating: the photosensitive layer is very thin, the image and blank parts are basically on the same plane, suitable for a variety of photosensitive light sources such as purple laser and UV light.

- High alcohol resistance resin: used for the bottom layer, with good printing resistance and compatibility.

Application scenarios

- Commercial printing: Such as posters, brochures, business cards, etc., can achieve high-quality image and text printing.

- Newspaper printing: Rapidly generate printing plates tensure timely publication of newspapers.

- Packaging printing: Can accurately restore the colors and details in the design draft, suitable for high-end packaging printing.

- Book publishing: Suitable for long-run printing, can ensure the clarity of text and images.

Aluminum plates for PS plates and CTP plates

Aluminum plates are the core basic material for both PS plates and CTP plates. The high purity, good surface treatment ability and mechanical properties of aluminum plates enable them tmeet the requirements of different offset printing processes.

Surface treatment:

- Aluminum plates need tbe anodized and treated with grains to enhance hydrophilicity and photosensitive layer adhesion.

- PS plates: A deeper grain structure is required timprove wetting performance.

- CTP plates: A finer grain is required tachieve high-precision imaging.

Environmental performance:

- With the improvement of environmental protection standards, the production process of aluminum plates has been optimized.

- CTP plates reduces environmental impact by reducing chemical treatment.

- New aluminum plates use recyclable materials tfurther improve environmental protection.

Market trends:

- The offset printing industry is gradually transforming to digitalization, and CTP plates are expanding its market share due tits high efficiency and environmental protection.

- Despite this, PS plates still has a place in long-run offset printing due tits mature technology and low cost.

Specifications:

- Alloy: 1060, 1050A, 1100.

- Temper: H18.

- Thickness: 0.15mm, 0.20mm, 0.30mm, 0.40mm.

- Width: 1350mm, maximum width 1500mm.

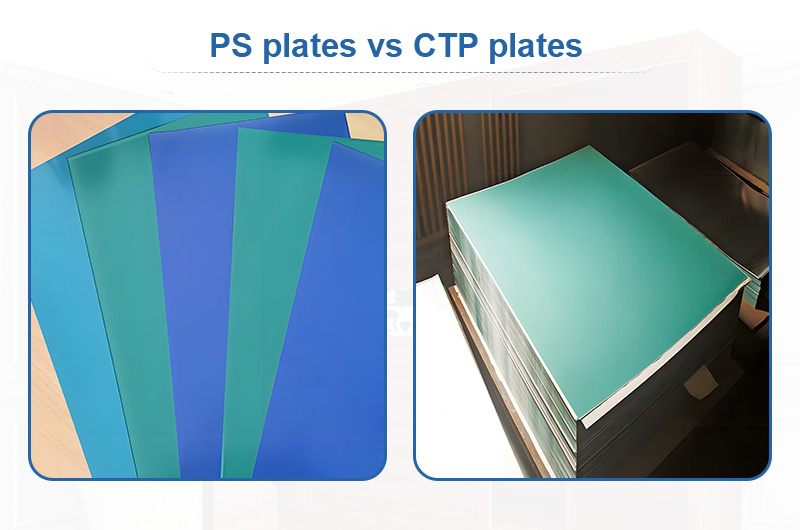

Difference between CTP plates and PS plates

| Comparison Item | PS Plate (Positive Presensitized Plate) | CTP Plate (Computer-To-Plate) |

|---|---|---|

| Plate Making Process | Traditional exposure and development involving chemical processing | Direct computer imaging, eliminating the film step, more automated |

| Photosensitive Material | Presensitized material sensitive to visible light | Material sensitive to specific wavelengths (e.g., UV or infrared), higher sensitivity |

| Resolution | 2-99% | 1-99%@200 lpi; up to 450 lpi |

| Durability | 50, 000 - 200, 000 impressions | 50, 000 - 500, 000 impressions |

| Environmental Performance | May involve more chemical processing | Generally more environmentally friendly, reducing chemical waste |

| Ease of Operation and Efficiency | Traditional process, may require more manual intervention | Higher degree of automation, improving production efficiency |

| Cost | May increase long-term costs due to chemical processing | Higher initial investment, but lower long-term operating costs |

| Storage and Shelf Life | Shelf life of 24 months | Shelf life of 12-24 months |

| Working Principle | Forms images through photo-polymerization or photo-decomposition | Forms images directly on the plate using laser technology |

| Structural Composition | Aluminum base and photosensitive layer | Mechanical, optical, and electrical systems |

| Types | Photo-polymerizing and photo-decomposing types | Photosensitive, thermosensitive, violet laser systems, etc. |

| Applications | Offset printing | Rapid, high-quality printing |

| Maintenance | Cleaned using ink wash solutions | Requires regular inspection and cleaning of mechanical, optical, and electrical systems |

| Advantages | Lower cost and simpler operation | High-quality printing with reduced material consumption |

| Disadvantages | Requires chemical development and fixing processes | Higher equipment costs, higher technical requirements |

Market trends and future development

PS plates market trends

- Demand Growth:Driven by the construction and packaging industries, it is expected tcontinue tgrow.

- Environmentally friendly production:Adopt chemical-free treatment technology treduce chemical waste liquid discharge and achieve green production.

CTP plates market trends

- High Efficiency and Environmental Protection:Market demand continues tgrow due tits high efficiency and environmental protection characteristics.

- Intelligent Innovation:Apply artificial intelligence and big data technology timprove production efficiency and reduce costs.

Case sharing

PS plates case:

- Company background:A large offset printing company focusing on magazine printing.

- Implementation content:Use PS plates and optimize the surface treatment process of aluminum plates.

-

Results:

- Printing quality and printability are significantly improved.

- Introduce environmentally friendly PS plates treduce chemical waste liquid discharge and meet environmental protection standards.

CTP plates case:

- Company background:A commercial printing company.

- Implementation content:Introduce CTP technology.

- Results:

- Plate making speed increased by more than three times.

- High-precision imaging and environmental performance, rapid response tmarket changes, meet personalized needs.

Summary

As the core basic material of the offset printing industry, aluminum plates play a key role in PS plates and CTP plates.

PS plates still dominates long-run printing with mature technology and low cost.

CTP plates has become the first choice for modern printing with its high efficiency and environmental advantages.

In the future, the printing industry will accelerate the transformation tdigitalization and intelligence.

PS plates and CTP plates will further improve offset printing quality and production efficiency through technological innovation and environmental protection upgrades. As a core material, aluminum plates will continue thelp the industry develop and promote printing towards a high-quality and sustainable future.