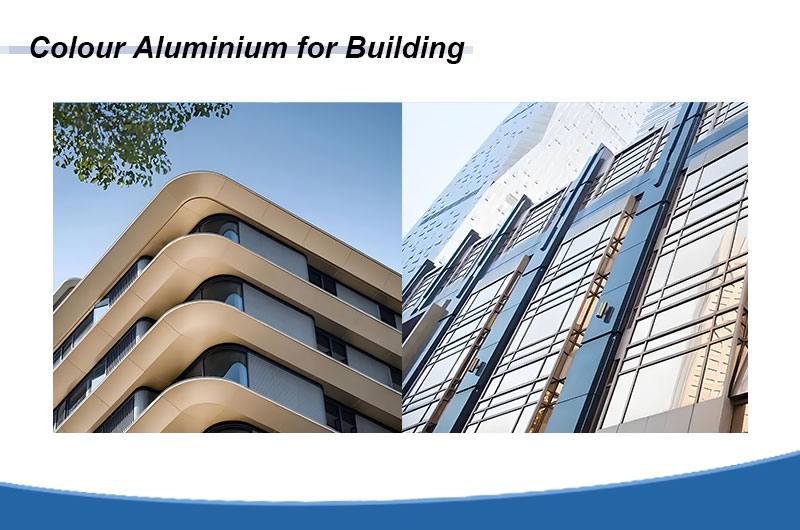

What is architectural colored aluminum

Architectural colored aluminum refers to colored aluminum alloy materials used in architectural decoration and structure. Common alloys are 1000 series aluminum alloys, such as 1050, 1060, 1100, 1200, 3000 series aluminum alloys, such as 3003, 3004, 3105, 5000 series aluminum alloys, such as 5005, 5052, 5454, etc. Common coatings are PVDF, PE.

Architectural colored aluminum not only enhances the appearance of the building, but also enhances its structural performance and durability. Architectural colored aluminum has more obvious advantages in color selection, corrosion resistance, UV resistance, etc.

Worthwill is committed to providing ideal color-coated aluminum products for your construction project!

Specifications

Alloy: 1050, 1060, 3003, 3004, 3105, 5005, 5052, 5454

Coating: PE, PVDF, Epoxy, Acrylic.

Coating thickness: according to your needs

Process: roller coating, spray coating, anodizing

Thickness: 0.2mm-10mm

Width: 100mm-2650mm

Length: customizable

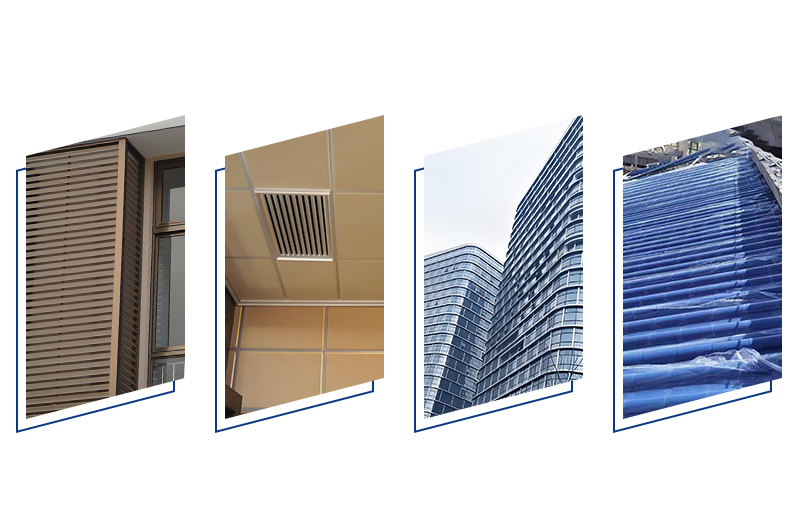

Application areas

Exterior wall system: used for decoration and insulation of building exterior walls, providing long-lasting color and excellent weather resistance.

Roof and ceiling: suitable for roof and ceiling materials, providing waterproof performance and beautiful appearance.

Door and window frames: used for door and window frames, enhancing their corrosion resistance and aesthetics.

Interior decoration: used for interior decoration such as walls, ceilings and partitions, adding color and design.

Roofing material

Aluminum roofing sheet

The color aluminum used for the roof is usually made of aluminum-magnesium-manganese alloy, Temper is mostly T5 or T6, Worthwill's roofing material, small color difference, uniform paint film, good formability and strength.

Alloy: 1050, 1060, 3003, 5052

Temper: O, H12, H22, H14, H24, H16, H26, H18

Film thickness:

- PE coating: generally 25-30μm

- PVDF coating: up to 40μm or more

Size:

- Thickness from 0.2mm to 6.0mm.

- Width from 300mm to 2900mm.

- Lengths less than 12.5m.

Surface treatment: mill finished, orange peel, worm pattern, can be covered with plastic film, Or according to your needs.

Wave type: Trapezoidal and curved.

Wave height: 10mm-55 mm.

Coating: Galvanized, PVDF, PE, HDP.

Standard: GB/T4438-2006、GB/T 3190、GB/T 3880, GB/T 228, GB/T 3199, or according to your needs.

Roofing materials can provide a wide range of color options, based on color cards or samples you provide.

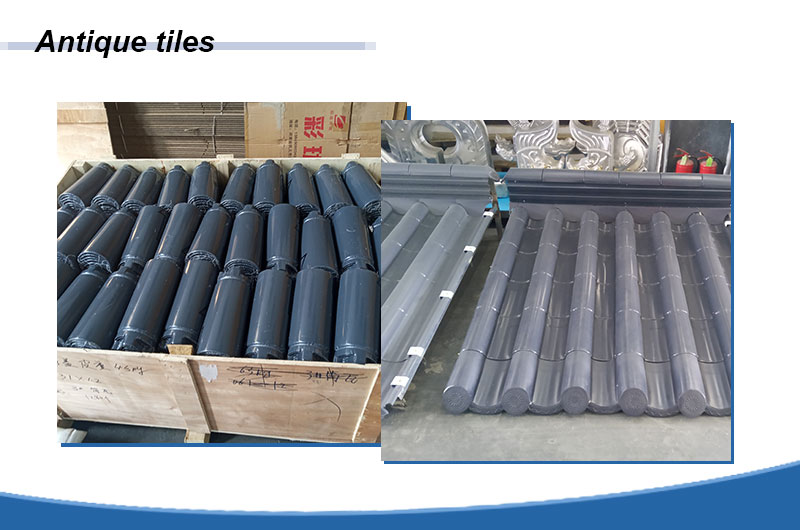

Antique tile

Antique aluminum tile is a new type of tile used in the roof of ancient buildings. It is mainly made by stamping and bending aluminum plates into antique-looking tiles.

Alloy: 3003, 3004, 5005, 5052

Temper: O

PVDF coating thickness: not less than 25μm

Base aluminum size: Thicknesses 1 or 1.2 mm or as per customer requests

Antique aluminum tiles have various structures. They can be designed and produced in different styles according to different building types to meet the overall architectural style.

Aluminum siding

Aluminum Siding is an aluminum sheet used for building exteriors. It is a popular building material that is widely used for its durability, low maintenance, and aesthetics.

Specifications

Alloy: 3003, 3105, 5005, 6061, 6063

Temper: O, H22, H24, H44, T3, T4, T5

Coating process: Powder coating, anodizing, electrophoretic coating

Coating: PVDF, 100% Acrylic Latex Paint, PE

Plank Length: Customizable, most aluminum sidings are 16 feet long (about 4.87 meters)

Exposed Face: 10mm-1500mm

Common panel widths include the following sizes:

- 3 inches (about 76.2 mm)

- 4 inches (about 101.6 mm)

- 6 inches (about 152.4 mm)

- 8 inches (about 203.2 mm)

- Thickness: 0.15mm-6mm

Common thicknesses include the following sizes:

- 3-inch panel: minimum metal thickness is 0.055 inches (about 1.40 mm)

- 4-inch panel: minimum metal thickness is 0.062 inches (about 1.60 mm)

- 6-inch panel: minimum metal thickness is 0.062 inches (about 1.60 mm)

- 8-inch panel: minimum metal thickness is 0.090 inches (about 2.29 mm)

Smooth aluminum siding panels

Provide a clean, minimalist look that fits modern architectural styles.

The surface is smooth and easy to clean and maintain.

Textured aluminum siding panels

Designed to mimic the look of traditional materials such as wood or stone, they offer the aesthetics of natural materials without the maintenance concerns of traditional materials.

Available in a variety of textures, such as faux wood or faux stone.

Insulated aluminum siding panels

With an extra layer of insulation, they enhance thermal efficiency.

In addition to their decorative purpose, they provide additional thermal insulation.

Vertical and horizontal aluminum siding panels

These panels can be installed vertically or horizontally, depending on the desired look and feel.

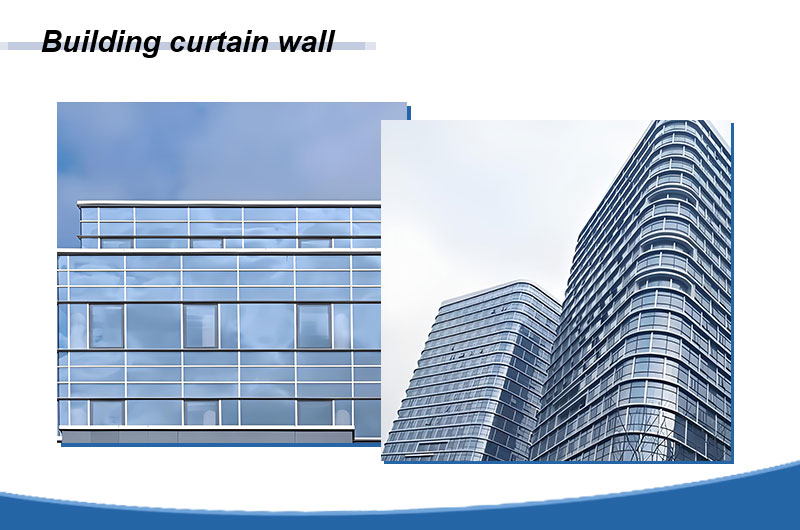

Building curtain wall

Aluminum curtain wall usually refers to a curtain wall with aluminum veneer as the surface material, which is formed by CNC bending and other technologies, and the surface is sprayed with decorative paint. The aluminum curtain wall has a unique texture, rich and lasting color, and can be diversified in appearance and shape, and can be perfectly combined with glass curtain wall materials and stone curtain wall materials.

The structure is mainly composed of panels, reinforcement ribs and corners. The corners can be directly bent and stamped by the panel, or they can be riveted on the small edge of the panel.

The reinforcing ribs are connected to the plate surface with electric welding screws to form a solid whole, which greatly enhances the strength and rigidity of the aluminum curtain wall

Alloy: 1100, 3003H24, 5005H24

Temper: O, H24, H26

Thickness: 1.5mm, 2.0mm, 2.5mm, 3.0mm, or customized

Color coating process: powder spraying

Coating: PVDF, PE

Paint film thickness: above 35μm

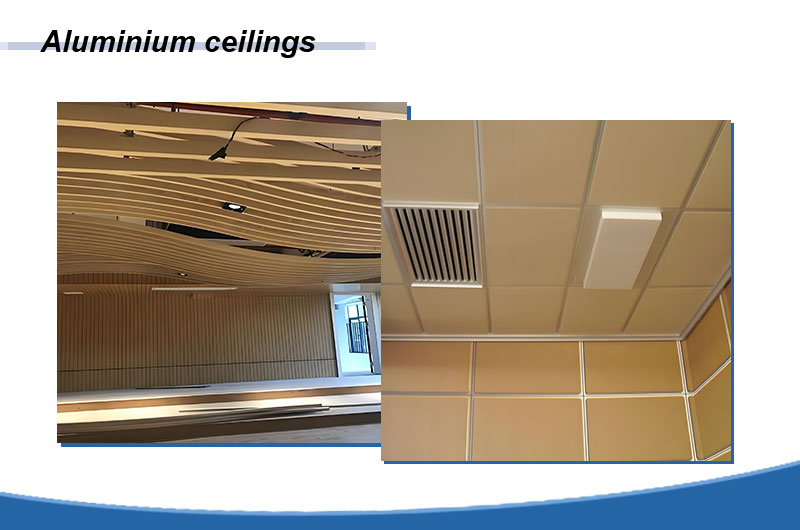

Aluminum ceiling

It is a ceiling material widely used in commercial and residential environments, with the characteristics of beauty, functionality, durability, and fire resistance.

Compared with traditional materials such as gypsum board, aluminum ceiling has better durability, fire resistance and easy maintenance. In addition, the inherent flexibility of aluminum allows for a wide range of design options to suit a variety of architectural styles

Specifications

Alloy: 1060, 1070, 3003, 5005, 5052

Temper: O, H14, H16, H24, H26

Types of aluminum ceilings

- Exposed grid systems

- Lay-in tile systems

- Baffle ceilings

- Aluminum ceiling strips

Aluminum gusset plate ceiling

Alloy: 1100, 1060, 3003, 5005, 5052

Dimensions: 300, 450, 500, 600 square plate

Base plate thickness: 0.3~0.6mm, 0.6~1.0mm, 1.0~1.2mm

Processing technology: die pressing

Aluminum square tube ceiling

Alloy: 1100, 3003, 5005

Temper: H18, H24

Bottom width: 20mm-400mm

Height: 20mm-600mm

Thickness: 0.4mm-3.5mm

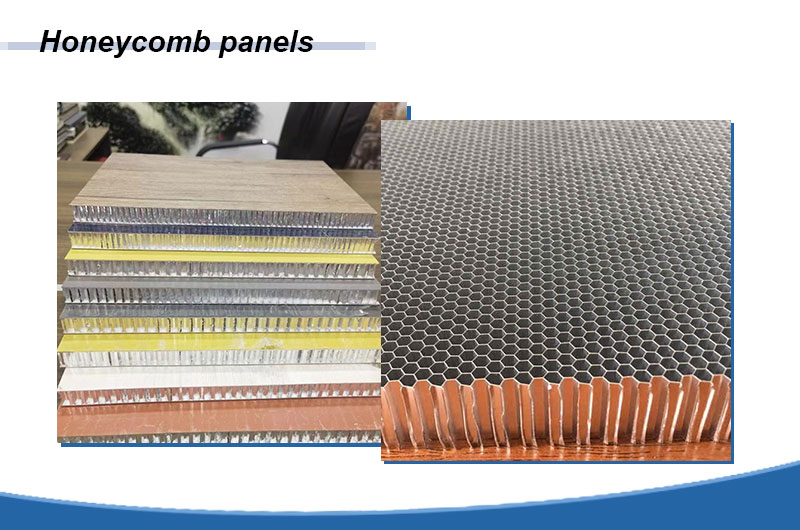

Honeycomb panel

Aluminum honeycomb panel adopts aluminum hexagonal honeycomb structure, with low density and high strength. It has sound insulation, heat insulation, fire resistance (B1 grade), smooth surface, corrosion resistance and strong earthquake resistance. It is suitable for building ceilings, not easy to deform, environmentally friendly and reliable.

Alloy: 3003, 5052

Temper: H18

Common thickness: 4mm, 8mm, 10mm, 15mm, 18mm, 25mm, 32mm, etc. (customizable)

Aluminum plate thickness: 0.5mm, 0.6mm, 0.8mm, 1mm, 1.5mm, Max 3mm, etc. (customizable)

Surface coating: PVDF, PE, anodized, mill finished, embossed, mirror, etc.

Width: 1000mm, 1220mm, 1250mm, 1500mm, Max 2440mm

Length: 2440mm, 3000mm, 3500mm, 5800mm

Aluminum honeycomb core thickness: 0.02mm, 0.04mm, 0.05mm, 0.06mm, 0.08mm Max 0.12mm

Aluminum honeycomb core size: Common specifications: 1/4" (6.35mm), 1/3" (8.47mm), 3/8" (9.53mm), 1/2" (12.7mm), etc.

Shutters

Alloys: 3104 3105 5052 5182

Temper: H19 H48

Thickness: 0.12mm-0.5mm

Width: 12.5mm-100mm, 100mm-1250mm

Inner diameter: 30mm-50mm, 300mm, 400mm, 500mm

Length: Customizable

Coating: PE, PVDF, HDP

Surface treatment process: Roller coat, anodizing, dye sublimation.

Standard: Meets industry standards such as ANSI WCMA A100.1-2018 and ASTM B221

Aluminum trim coil

Aluminum trim coil It is a kind of aluminum coil, usually a color-coated coil with a coating on the surface, used for decorative, protective or restorative purposes.

For example, it can be used to trim the exterior of a building, decorate or protect the edges around window frames and door frames, eaves and gables, and add a protective layer to damaged stairs, tables, and chairs to achieve the purpose of repair, protection and decoration.

Alloy: 1100, 3003, 3105, 5005, 5052

Temper: O, H12, H14, H22, H24

Width: 10''- 24'',

Thickness: 0.019''- 0.024''

Length: 50' -100'

Coating process: Roller coating, power spraying

Coating: PVDF, PE, PVC, Q800 TuffTech Coating

Surface treatment: Brushed finish, mirror polishing, embossed finish, painted finish, anodized finish, mill finish

Aluminum gutter coil

Aluinum gutter coil is a type of color-coated aluminum sheet, which is mainly used in rainwater mobile phones and guide systems in construction projects, and plays a very critical role in the overall construction. The advantages of aluminum gutter coil include simple installation, convenient maintenance, long life, light weight, etc.

Alloy: 3003, 3105

Thickness: 0.6 - 0.9 mm, .032””.027’’

Width: 200 - 800 mm

Coating: PE/HDPE/PVDF

Color: white, black, bronze, clay, classic cream, dove gray, Eggshell, green, Ivory, musket brown, pearl gray, red, royal brown, wicker

Why choose our architectural color coated aluminum?

Professional customization: Provide customized services, customized size, shape and color according to your specific needs.

Quality assurance: Through strict quality control process, ensure that each product has excellent performance.

Technical support: Provide professional technical support to help you choose the most suitable color coated aluminum material for your project.

Service commitment: Provide excellent customer service, including fast response and professional after-sales service.