Aluminum shutters are made of high-quality aluminum sheets or coils, which are treated with paint and will not corrode or rust.

Aluminum alloy shutters feel light and thin in the hand, have beautiful shape, and high strength. They are a very good material.

What’s aluminum shutter?

Aluminum shutters are usually composed of a series of parallel blades, which can be opened and closed manually or electrically. They are mainly used for sunshade, ventilation and privacy protection. They can be fixed on windows or doors to provide flexible light and sight control.

Aluminum roller shutter consists of a series of rolled aluminum blades, usually mounted on tracks, that can be rolled up and unrolled by a motor or manually. They are primarily used for anti-theft and security purposes and are commonly used on commercial and residential exterior and interior doors and windows.

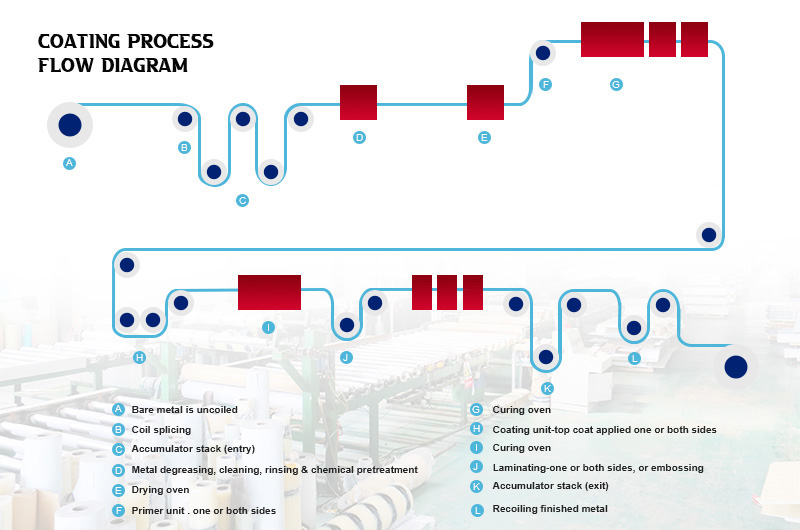

How are coated or prepainted aluminum for shutter made?

Aluminum shutters are mainly divided into two materials according to their uses.

Below are the common specifications of aluminum coil for shutters.

| Item | HP material | HP material |

| Application | Aluminium roller shutter slats | Aluminium roller shutter box |

| Alloy | EN AW 3005 H46 or 3105 H46 | 3105 H46 |

| Thickness | 0.25 mm -0.4 mm | 0.6 mm - 0.8 mm |

| Width | 100-150 mm | 85-500 mm |

| Paints | Pur-Pa technology | PE |

| Paints thickness | min 22 µm | 25 µm |

| Paints gloss | 30 ± 5 | 50 |

Different aluminum alloy comparison

Aluminum roller shutters are made up of two parts, the aluminum substrate and the paint coating. The most commonly used alloys on the market are 3003, 3005 and 3105 alloys.

Below is a comparison of these three alloys. Currently, European countries mostly use 3005 and 3105, while the Middle East and Southeast Asian countries mostly use 3003.

3003 Alloy content and mechanical properties

| 3003 Alloy content | |||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | / | / | 0.1 | / | 0.15 | Remain |

| 3003 Mechanical properties | |||||||||

| temper | Thickness (inch) | Tensile Strength | Yield Strength | Elongation ( min %) | |||||

| Min (ksi) | Max (ksi) | Min (ksi) | Max (ksi) | ||||||

| H12 OR H22 | 0.017-0.031 | 16 | 22 | 11 | / | 4 | |||

| 0.032-0.050 | 16 | 22 | 11 | / | 5 | ||||

| 0.051-0.113 | 16 | 22 | 11 | / | 6 | ||||

| 0.114-0.161 | 16 | 22 | 11 | / | 7 | ||||

| 0.162-0.249 | 16 | 22 | 11 | / | 8 | ||||

| 0.250-0.499 | 16 | 22 | 11 | / | 9 | ||||

| 0.500-2.000 | 17 | 23 | 12 | / | 10 | ||||

| H14 or H24 | 0.009-0.012 | 19 | 25 | 16 | / | 1 | |||

| 0.013-0.019 | 19 | 25 | 16 | / | 2 | ||||

| 0.020-0.030 | 19 | 25 | 16 | / | 3 | ||||

| 0.032-0.050 | 19 | 25 | 16 | / | 4 | ||||

| 0.051-0.113 | 19 | 25 | 16 | / | 5 | ||||

| 0.114-0.161 | 19 | 25 | 16 | / | 6 | ||||

| 0.162-0.249 | 19 | 25 | 16 | / | 7 | ||||

| 0.250-0.499 | 19 | 25 | 16 | / | 8 | ||||

| 0.500-1.000 | 20 | 26 | 17 | / | 10 | ||||

| H16 OR H26 | 0.006-0.019 | 23 | 29 | 20 | / | 1 | |||

| 0.020-0.031 | 23 | 29 | 20 | / | 2 | ||||

| 0.032-0.050 | 23 | 29 | 20 | / | 3 | ||||

| 0.051-0.162 | 23 | 29 | 20 | / | 4 | ||||

3105 Alloy content and mechanical properties

| 3105 Alloy content | |||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | 0.4 | 0.1 | 0.15 | Remain |

| 3105 Mechanical properties | |||||||||

| Temper | Thickness (inch) | Tensile Strength | Yield Strength | Elongation(min %) | |||||

| Min (ksi) | Max (ksi) | Min (ksi) | Max (ksi) | ||||||

| H12 | 0.017-0.019 | 19 | 26 | 15 | / | 1 | |||

| 0.020-0.031 | 19 | 26 | 15 | / | 1 | ||||

| 0.032-0.050 | 19 | 26 | 15 | / | 2 | ||||

| 0.051-0.080 | 19 | 26 | 15 | / | 3 | ||||

| H14 | 0.013-0.019 | 22 | 29 | 18 | / | 1 | |||

| 0.020-0.031 | 22 | 29 | 18 | / | 1 | ||||

| 0.032-0.050 | 22 | 29 | 18 | / | 2 | ||||

| 0.051-0.080 | 22 | 29 | 18 | / | 2 | ||||

| H16 | 0.013-0.031 | 25 | 32 | 21 | / | 1 | |||

| 0.032-0.050 | 25 | 32 | 21 | / | 2 | ||||

| 0.051-0.080 | 25 | 32 | 21 | / | 2 | ||||

| H22 | 0.013-0.019 | 19 | / | 15 | / | 3 | |||

| 0.020-0.031 | 19 | / | 15 | / | 4 | ||||

| 0.032-0.050 | 19 | / | 15 | / | 5 | ||||

| 0.051-0.080 | 19 | / | 15 | / | 6 | ||||

| H24 | 0.013-0.019 | 22 | / | 18 | / | 2 | |||

| 0.020-0.031 | 22 | / | 18 | / | 3 | ||||

| 0.032-0.050 | 22 | / | 18 | / | 4 | ||||

| 0.051-0.080 | 22 | / | 21 | / | 6 | ||||

| H26 | 0.013-0.031 | 25 | / | 21 | / | 3 | |||

| 0.032-0.050 | 25 | / | 21 | / | 4 | ||||

| 0.051-0.080 | 25 | / | 21 | / | 5 | ||||

3005 Alloy content and mechanical properties

| 3005 Alloy content | |||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.1 | 0.25 | 0.1 | 0.15 | Remain |

| 3005 Mechanical properties | |||||||||

| Temper | Thickness (inch) | Tensile Strength | Yield Strength | Elongation(min %) | |||||

| Min (ksi) | Max (ksi) | Min (ksi) | Max (ksi) | ||||||

| H12 | 0.017-0.019 | 20 | 27 | 17 | / | 1 | |||

| 0.020-0.050 | 20 | 27 | 17 | / | 2 | ||||

| 0.051-0.113 | 20 | 27 | 17 | / | 3 | ||||

| 0.114-0.161 | 20 | 27 | 17 | / | 4 | ||||

| 0.1620.249 | 20 | 27 | 17 | / | 5 | ||||

| H14 | 0.009-0.031 | 24 | 31 | 21 | / | 1 | |||

| 0.032-0.050 | 24 | 31 | 21 | / | 2 | ||||

| 0.051-0.116 | 24 | 31 | 21 | / | 3 | ||||

| 0.114-0.249 | 24 | 31 | 21 | / | 4 | ||||

| H16 | 0.006-0.031 | 28 | 35 | 25 | / | 1 | |||

| 0.032-0.113 | 28 | 35 | 25 | / | 2 | ||||

| 0.114-0.162 | 28 | 35 | 25 | / | 3 | ||||

| H28 | 0.016-0.019 | 31 | / | 27 | / | 1 | |||

| 0.020-0.031 | 31 | / | 27 | / | 2 | ||||

| 0.032-0.050 | 31 | / | 27 | / | 3 | ||||

| 0.051-0.080 | 31 | / | 27 | / | 4 | ||||

Coating technology and paints comparison

At the same time, different paints add color and vitality to the shutters and roller shutters. PE paint is the most common in the production of shutters. PU and PVDF paints are only used in some developed countries due to their high costs.

Coating technology

Paints comparison

Polyester Paints (PE Paints)

- Polyester primer and polyester finishing coat.

- Layering 8-40um (depending on color and application).

- Excellent ductility.

- Extensive color range, high degree of gloss.

- Limited durability regarding UV and weathering.

PU/PA Paints

- Extreme form and temperature stability.

- Weathering resistant.

- Versatile colour range.

- High mechanical durability.

- Proven in saltwater, industrial and sun intensive climates.

- Especially for roller shutter slats and roller shutter box ect.

PVDF Paints

- Excellent weathering and UV properties.

- Excellent color and gloss durability.

- Excellent corrosion and chemical resistance.

- Very good ductility.

- Double coating system consisting of primer and finishing layers.

- The layering thickness is approximately 25 µm.

- The degree of gloss at a 60° measuring angle is approximately 20 units (Gardner).

Epoxy Paints

- Outstanding chemical resistance.

- High flexibility.

- Ideal for interior use .

The benefits of aluminum coil for shutter

- High strength, not easy to deform, light weight and durable.

- Accurate size, high processing precision, and extrusion resistance.

- Rich and diverse colors, good gloss, good feel, excellent resilience and toughness.

- Not afraid of ultraviolet rays, high heat reflectivity, can help save energy.

Client requirements

Due to the particularity of this product, most of our customers are shutter manufacturers. The customer's workshop will prepare the corresponding cutting board, bending and forming machine for easy processing at any time.

Then we supply customers with color-coated or prepainted aluminum coil. After decades of export experience, we found that the basic requirements of shutter manufacturers for color-coated aluminum coils are as follows:

- Good paint adhesion.

- The paint cannot fall off or produce color difference during subsequent processing.

- The width tolerance is strictly controlled +/-1 mm.

- The width of the shutter production must be consistent before it can enter the machine bending and other subsequent processing.

- Each aluminum coil is packaged separately according to the color, and as much as needed is taken.

The difference between shutter and roller shutter

Aluminum shutter

- Structure: Parallel blades, manually or electrically controlled.

- Function: Sunshade, ventilation, privacy protection.

- Application: Balconies, terraces, interior decoration, places requiring good sight control and natural light.

Aluminum roller shutter

- Structure: Rolled-up aluminum blades, mounted on tracks, motorized or manually controlled.

- Function: Anti-theft, security protection.

- Application: Store front windows, warehouses, residential exterior doors and windows, places requiring high security.