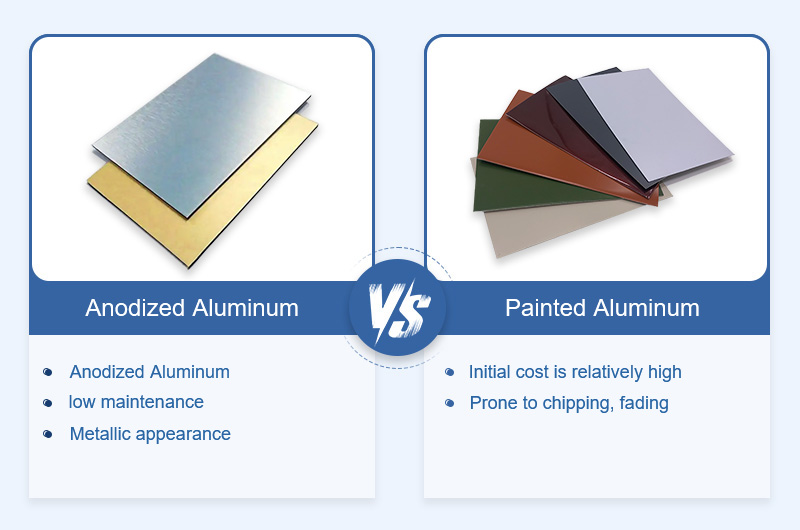

Anodized Aluminum vs. Painted Aluminum

Anodized aluminum and painted aluminum are two common surface treatments for aluminum, each with distinct characteristics.

Anodized aluminum sheet undergoes an electrochemical process to form a durable, hard oxide layer that is integral to the metal, offering excellent corrosion and abrasion resistance, low maintenance, and a rich metallic appearance. It is ideal for outdoor applications and high-traffic areas. However, it has limited color options and higher initial costs.

Painted aluminum, on the other hand, involves applying an organic coating to the surface, providing a wide range of colors and patterns. It is more cost-effective for large-scale production and suitable for indoor use. However, painted surfaces are more prone to chipping, fading, and requiring regular maintenance.

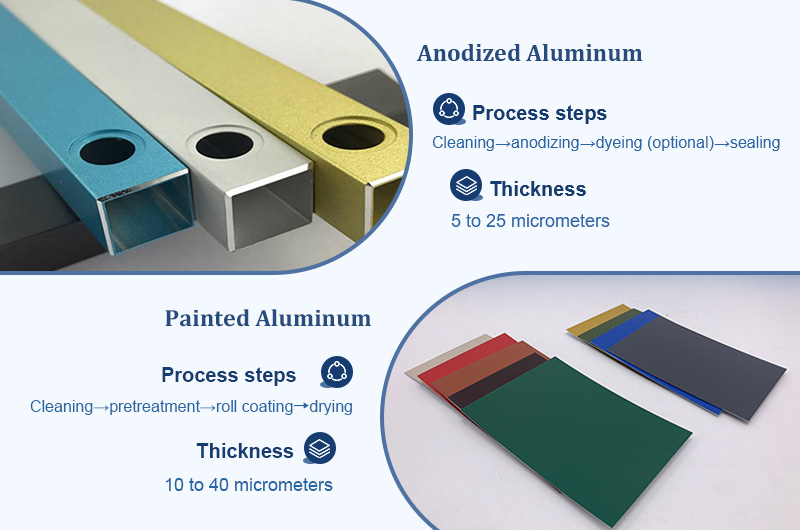

Process & Structure

Anodized Aluminum: Involves an electrochemical process where aluminum is submerged in an acid bath and subjected to an electric current, forming a thick, durable aluminum oxide layer. This layer is integral to the metal, with dyes infused into porous oxide before sealing.

Painted Aluminum: A coating (liquid or powder) is applied to the surface. Requires surface preparation (priming) for adhesion. The paint sits atop the metal.

Durability

Anodized: Superior scratch and wear resistance due to the hard oxide layer (especially Type III "hard coat"). Resists chipping and peeling.

Painted: Prone to chipping, scratching, and UV fading over time. Durability varies with paint type (e.g., powder coating is more robust).

Aesthetic & Color Options

Anodized: Metallic sheen with translucent, uniform colors. Limited to darker hues and metallic tones. Maintains appearance even if scratched.

Painted: Broad color range, finishes (glossy/matte), and effects (e.g., textures). Opaque and vibrant but may fade or show metal when damaged.

Corrosion & Environmental Resistance

Anodized: Excellent corrosion resistance; oxide layer is inert. Highly UV-resistant, minimizing fading.

Painted: Good corrosion protection if applied correctly, but susceptible to UV degradation and chemical wear.

Cost & Maintenance

Anodized: Higher initial cost (process-intensive) but lower maintenance. No touch-ups needed.

Painted: Lower upfront cost but potential for higher long-term maintenance (touch-ups, repainting).

Applications

Anodized: Ideal for high-traffic, outdoor, or architectural uses (window frames, marine hardware).

Painted: Preferred for consumer goods, automotive parts, and signage where color variety is key.

Environmental Impact

Anodized: Uses chemicals/electricity but produces no VOCs. Fully recyclable.

Painted: May involve VOCs (except powder coating). Paint removal needed before recycling.

Conductivity

Both are generally non-conductive due to their coatings.

Conclusion

Choose anodized aluminum for durability, UV resistance, and low maintenance in harsh environments. Opt for painted aluminum when vibrant colors, cost flexibility, or design versatility are priorities. Consider lifecycle costs, environmental conditions, and aesthetic requirements when deciding.