Aluminum Defects

Common aluminum sheet defects: surface oil and scratches caused by equipment mishandling or contaminated rollers.

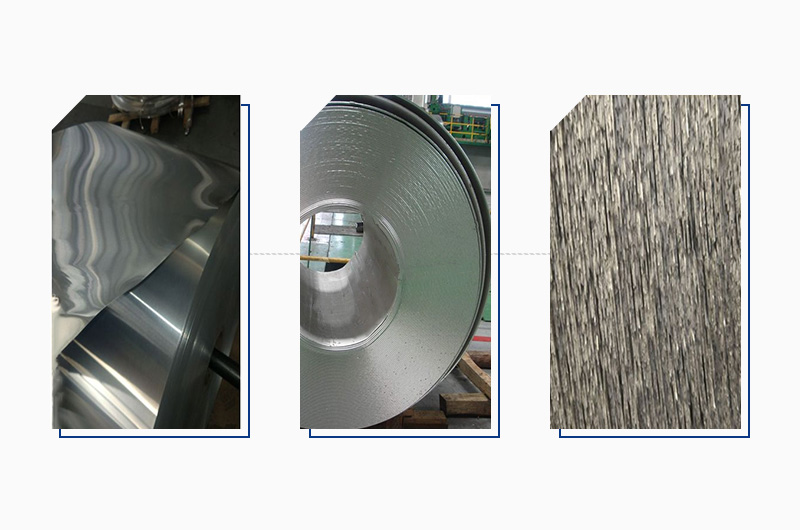

Common aluminum coil defects: delamination, waviness, and loose winding due to poor process control or handling errors.

Common casting aluminum defects : surface scratches, cracks, and coarse grains resulting from unstable parameters or melting / equipment issues.

Type of Aluminum Defects

Critical Defects (Unacceptable)

- Severe structural damage: Through-holes, inclusions, overburning, etc.

- Corrosion-related damage: Corrosion, diffusion, white spots, etc.

- Structural integrity failure: Tears, cracks, etc.

- Non-compliance with mechanical properties or dimensional tolerances.

Acceptable Defects (Conditionally Acceptable)

- Surface defects (e.g., bubbles, waves, scratches) with limited area and depth.

- Minor defects (e.g., folds, non-metallic inclusions).

- Defects matching standard samples (e.g., small black spots, creases).

Other Defects (Unspecified)

Side bending, oil stains, water stains, etc., requiring evaluation against specific standards.

Surface Defects

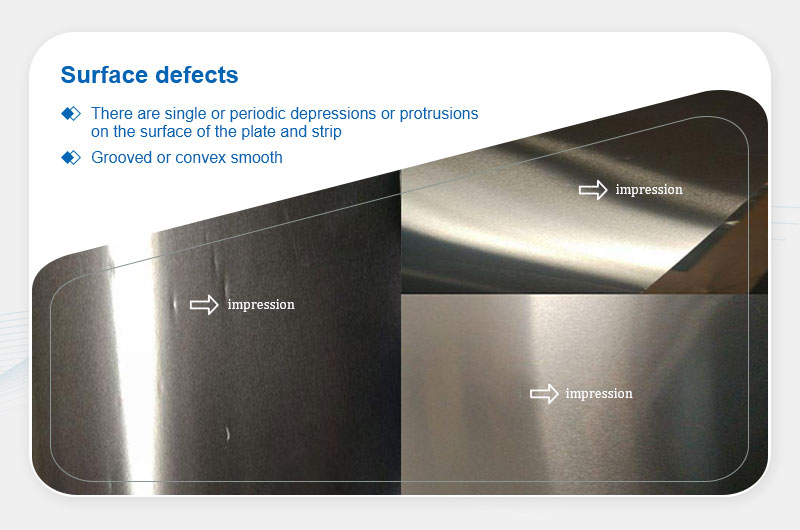

Imprints

Definition: Single or periodic depressions/protrusions on the surface, smooth in texture.

Main Causes:

- Metal debris or contaminants on rolls, work rolls, or coating/oiling rollers.

- Defects or contaminants on process equipment (e.g., calenders, straighteners, feed/guide rollers).

- Dirty, uneven, or protruding coiling sleeves.

- Foreign particles adhering during coiling.

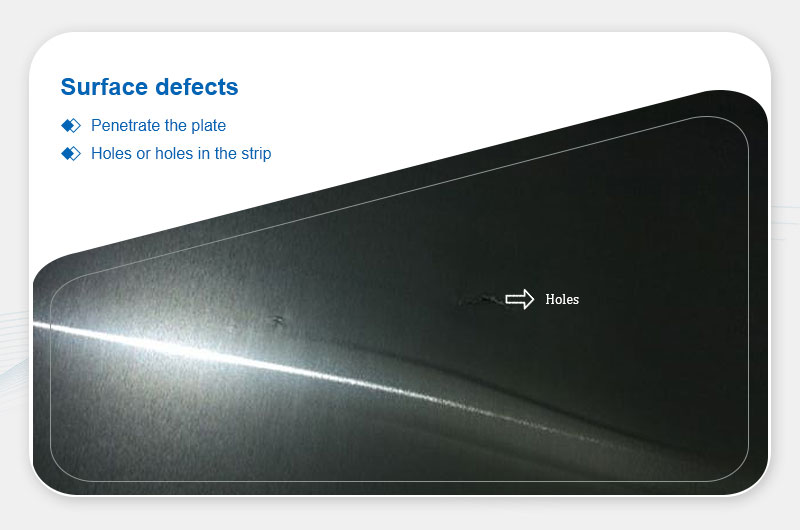

Holes

Definition: Penetrating holes or voids in the plate/strip.

Main Causes:

- Slag inclusions, scratches, or pre-existing holes in the billet before rolling.

- Detachment of embedded particles during rolling.

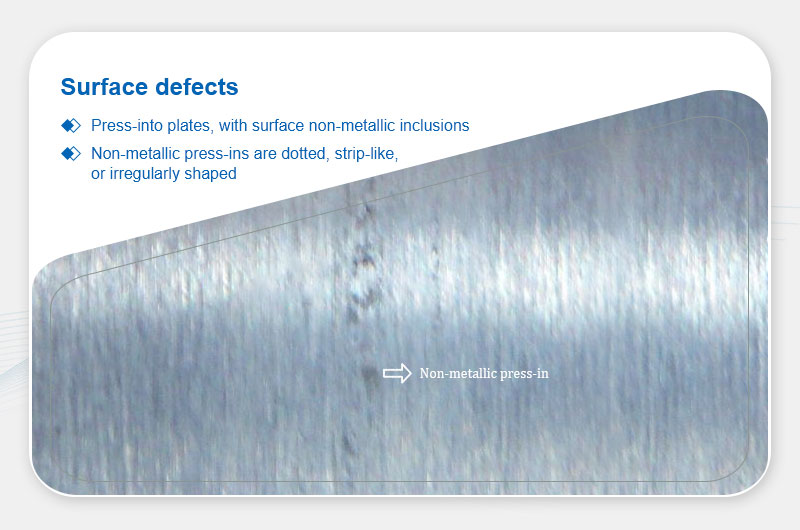

Non-Metallic Inclusions

Definition: Non-metallic particles (dots, streaks, irregular shapes) embedded on the surface.

Main Causes:

- Contaminated equipment or environment.

- Dirty rolling lubricants.

- Residual non-metallic debris in billet surface scratches or oil residues.

- Foreign particles falling onto the surface during production.

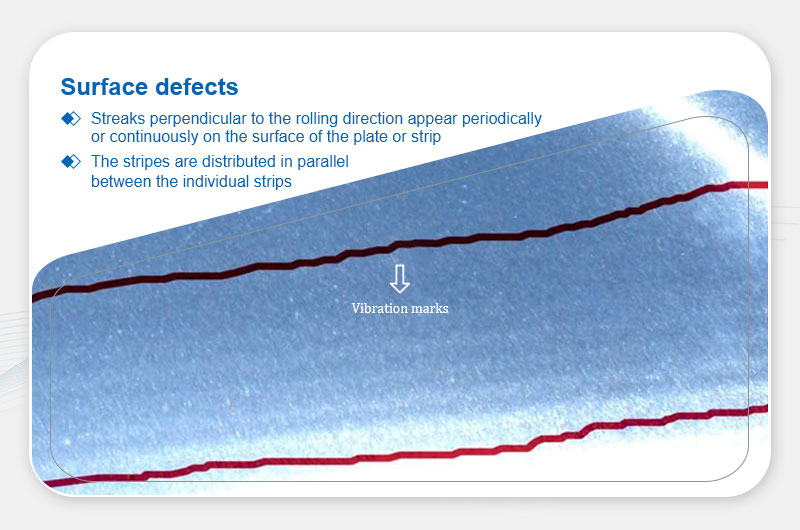

Vibration Marks

Definition: Stripes perpendicular to the rolling direction, often spanning the entire width.

Main Causes:Vibrations in rolling mills, straighteners, or calenders.

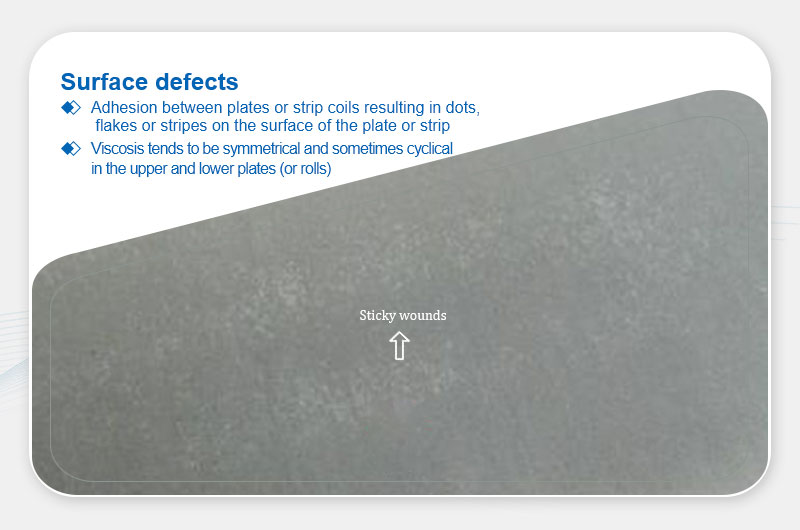

Adhesion Marks

Definition: Symmetric or periodic point/streak marks from layer-to-layer adhesion.

Main Causes:

- Localized pressure on hot plates/strips.

- Excessive tension during cold rolling or coiling.

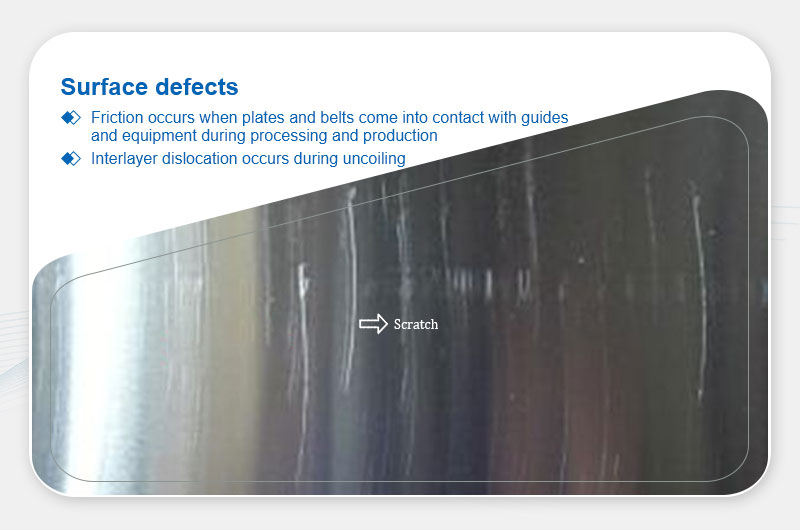

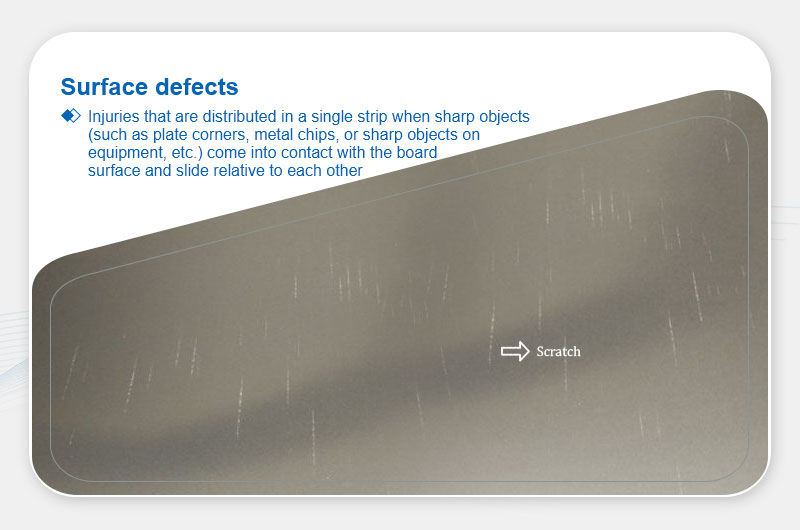

Scratches

Definition: Clustered abrasions from interlayer friction or contact with equipment.

Main Causes:

- Friction with guides or equipment during processing.

- Layer misalignment during annealing or uncoiling.

- Improper handling during finishing or packaging.

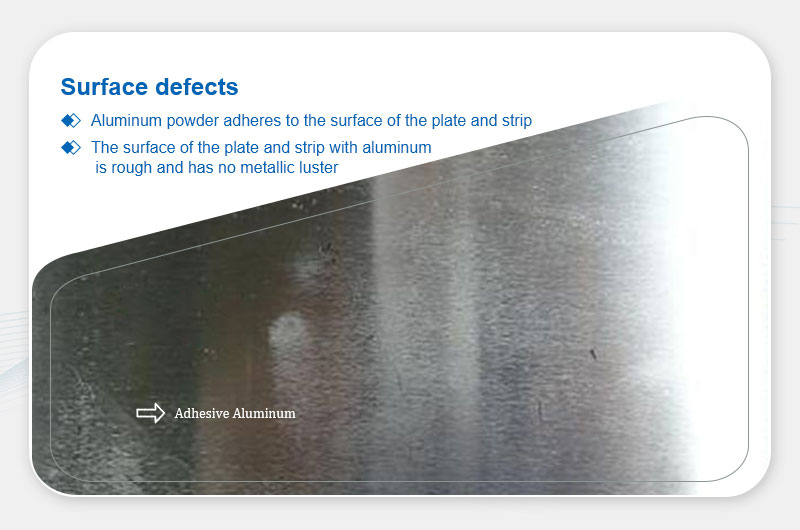

Aluminum Adhesion

Definition: Rough, non-glossy surfaces due to adhered aluminum powder.

Main Causes:

- High billet temperature during hot rolling.

- Excessive rolling speed/pressure.

- Poor-quality lubricants.

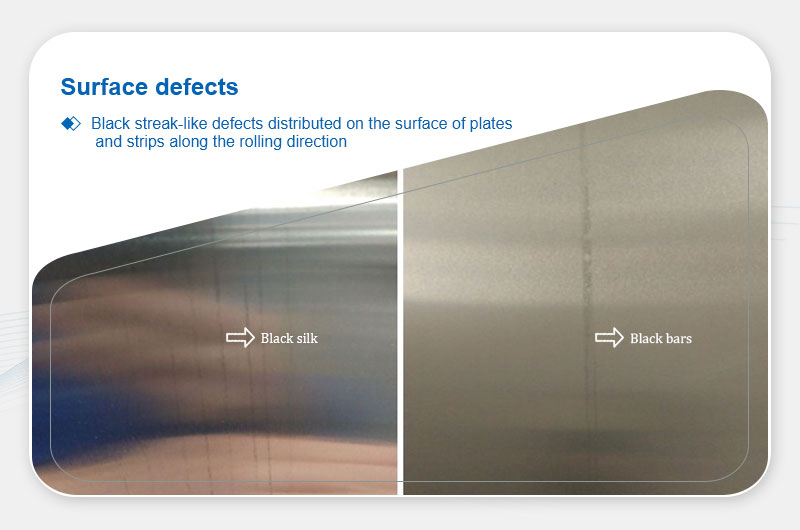

Black Streaks

Definition: Black lines along the rolling direction.

Main Causes:

- Poor lubrication or contaminated lubricants.

- Surface scratches or dirty guides.

- Incomplete billet milling or oxide inclusion during rolling.

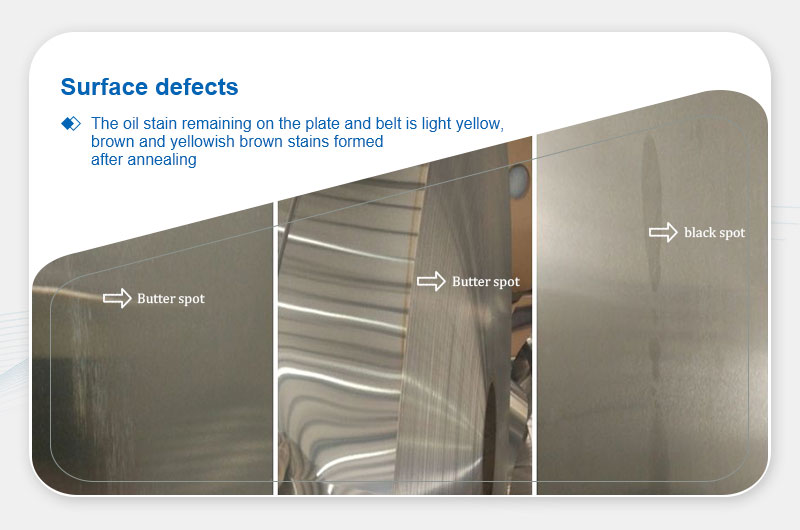

Oil Stains

Definition: Yellow / brown residues from oil oxidation during annealing.

Main Causes:

- Unsuitable rolling oil properties.

- Incomplete oil removal before annealing.

- Contamination with high-viscosity oils.

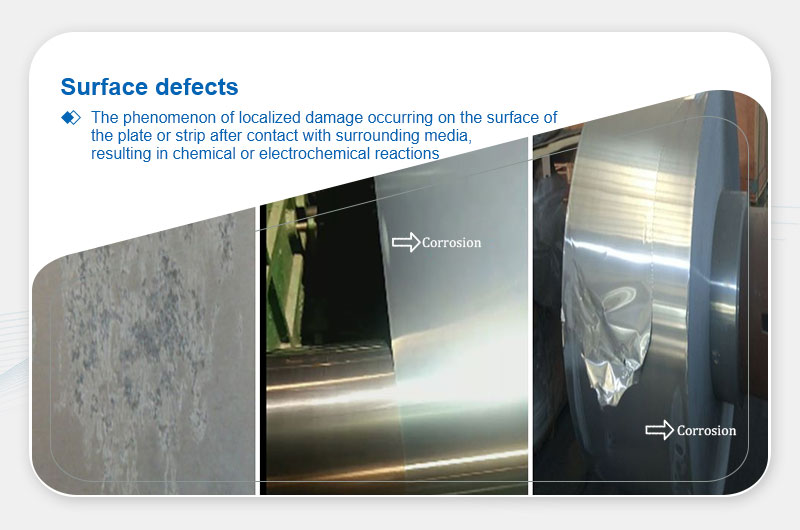

Corrosion

Definition: Chemical/electrochemical surface damage, often with loss of metallic luster.

Main Causes:

- Residual acids/alkalis after quenching.

- Moisture exposure during storage/transport.

- Water-contaminated lubricants or compressed air.

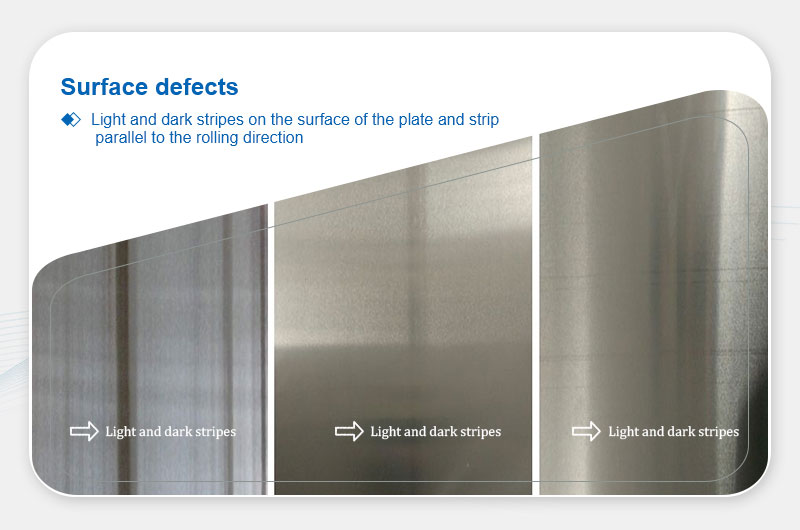

Bright/Dark Stripes

Definition: Parallel alternating glossy/matte stripes.

Main Causes:

- Poor billet surface quality or uneven lubrication.

- Roller defects or material heterogeneity.

- Rolling narrow strips before wide ones ("wide-narrow marks").

Scoring

Definition: Linear scratches from sharp objects.

Main Causes:

- Aluminum buildup on hot mill guides.

- Sharp edges on cold mill equipment.

- Improper handling during finishing/packaging.

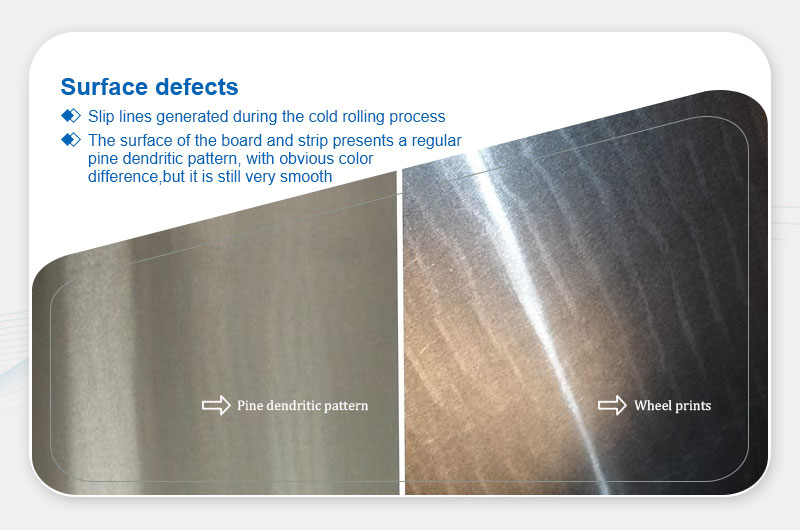

Pine-Tree Patterns/Wheel Marks

Definition: Slip lines with glossy/matte contrast, smooth to touch.

Main Causes:Poor lubrication, excessive cold rolling reduction, or low tension.

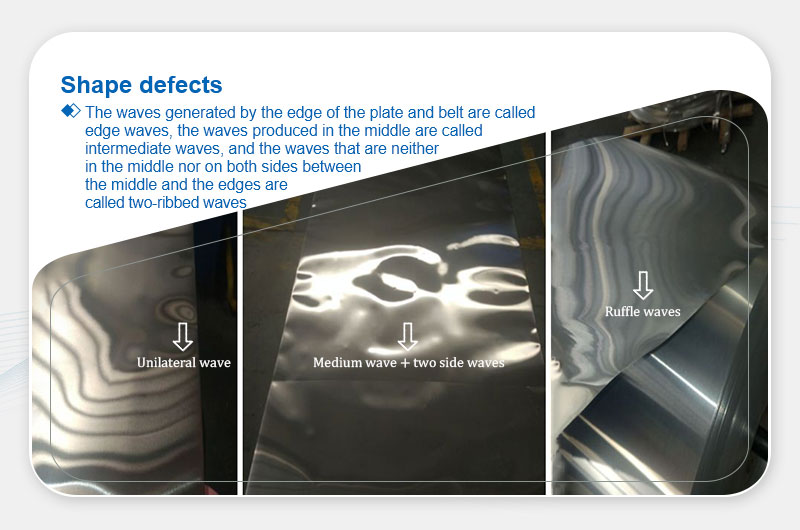

Shape Defects

Waves

Definition: Uneven deformation causing edge, center, or localized waviness.

Main Causes:

- Uneven roll gaps or lubrication.

- Improper reduction distribution or poor incoming plate flatness.

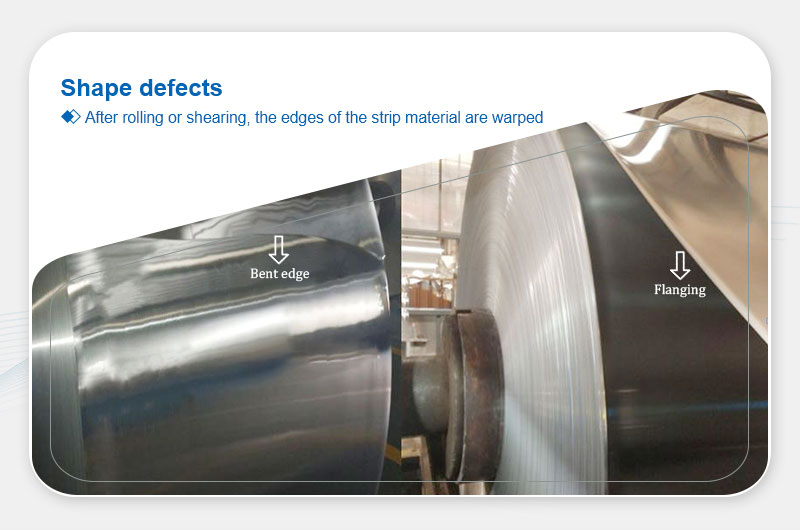

Edge Warping

Definition: Curled edges after rolling/shearing.

Main Causes:

- Excessive rolling reduction.

- Uneven lubrication or improper shear blade alignment.

Warping and Buckling

Definition: Irregular bending from uneven stress or thermal effects.

Main Causes:Material inhomogeneity, residual stresses, temperature/humidity fluctuations.

Dimensional Defects

Thickness Deviation

Main Causes:Incorrect rolling reduction or faulty thickness gauges.

Width/Length Deviation

Main Causes:Misadjusted shearing equipment or unaccounted thermal shrinkage.

Appearance Defects

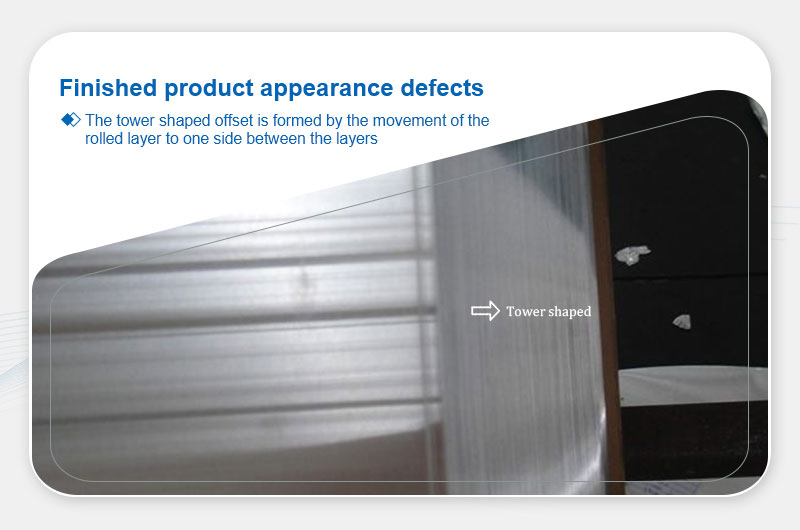

Tapered Coils

Definition: Layer misalignment forming a "tower" shape.

Main Causes:

- Poor incoming flatness or tension control.

- Faulty coiling alignment systems.

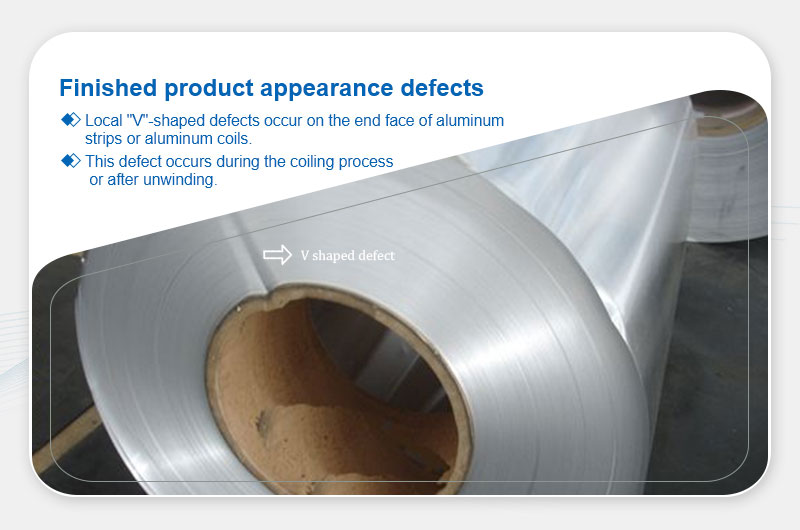

V-Shaped Defects

Definition: Local "V" notches on coil end faces.

Main Causes:

- Improper tension during coiling.

- Defective cores or uneven stress distribution.

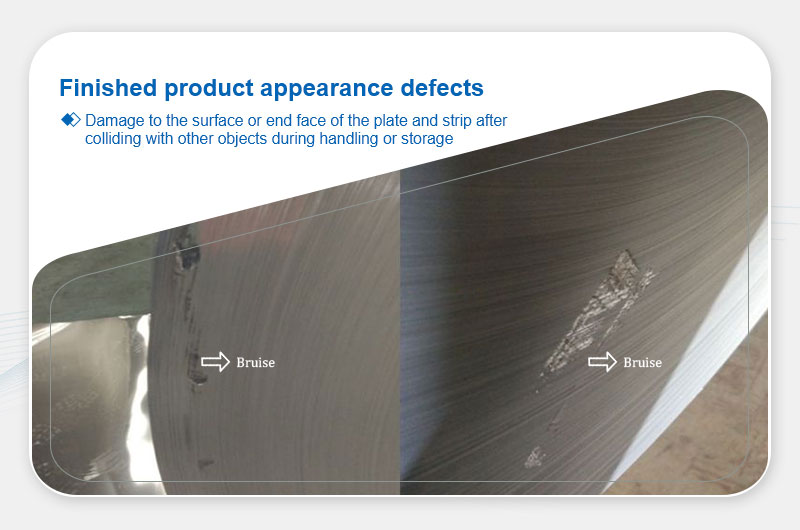

Impact Damage

Definition: Collision-induced surface/edge damage.

Main Causes:Mishandling during transport/storage.

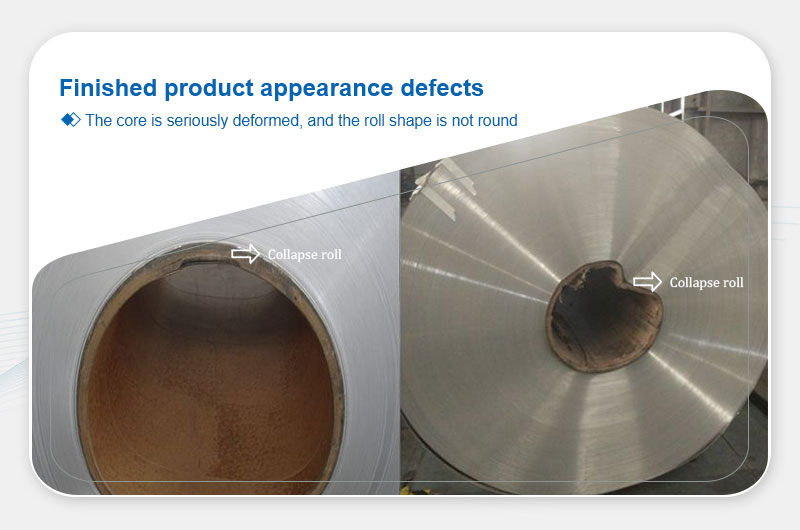

Collapsed Coils

Definition: Deformed cores or non-circular coils.

Main Causes:Incorrect coiling tension, external pressure, or weak cores.

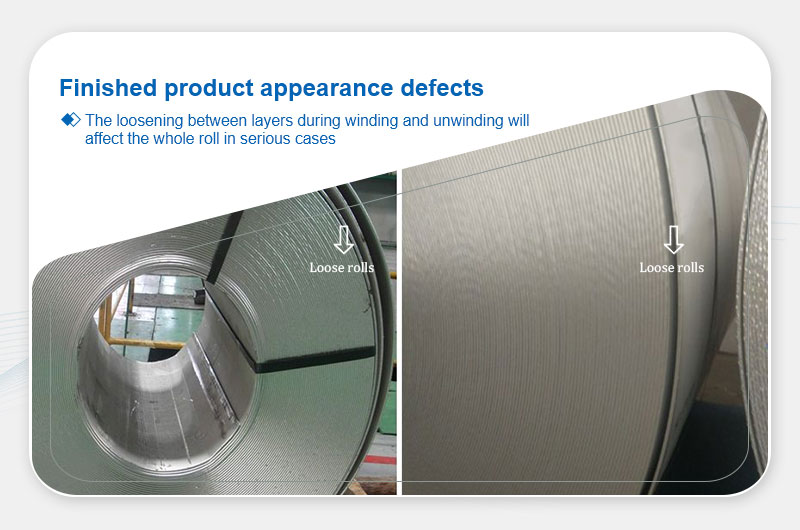

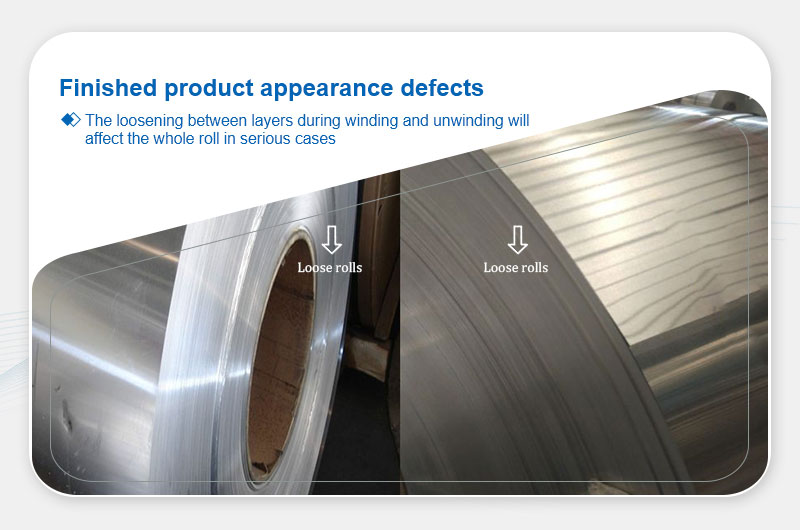

Loose Coils

Definition: Interlayer slippage during coiling/uncoiling.

Main Causes:Low tension during coiling or unsecured strapping.

Layer Misalignment

Definition: Irregular end face stacking.

Main Causes:Poor incoming flatness, uneven tension, or misaligned rollers.

Edge Defects

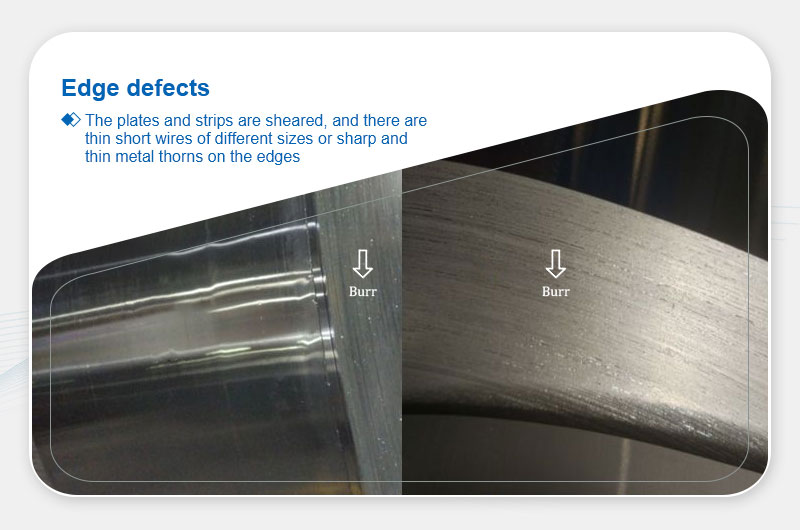

Burrs

Definition: Fine metal protrusions along sheared edges.

Main Causes:Dull blades, poor lubrication, or incorrect blade settings.

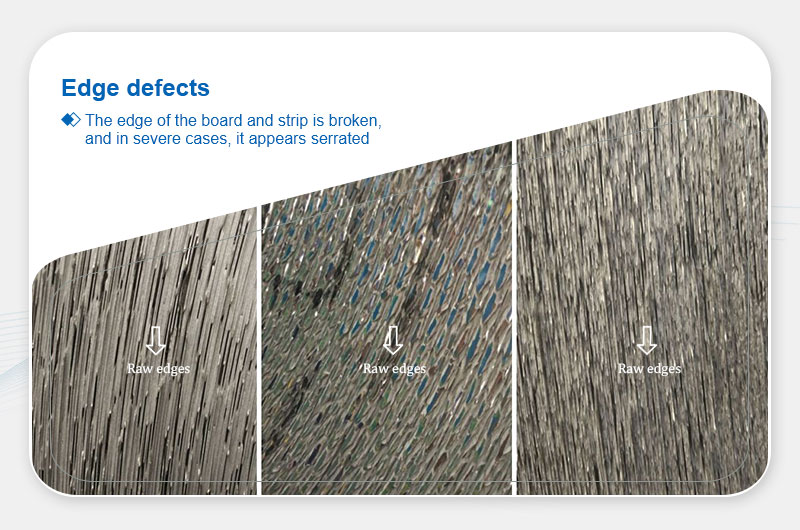

Edge Cracks

Definition: Jagged edge fractures.

Main Causes:Low billet temperature, improper annealing, or excessive reduction.

Edge Waviness

Definition: Wavy edges from uneven rolling extension.

Main Causes:Roll wear, temperature gradients, or material stress.

Edge Dents

Definition: Localized edge depressions.

Main Causes:Contact with damaged rollers or uneven cooling.

Microstructural/Performance Defects

Failed Mechanical Properties

Main Causes: Non-compliant chemical composition, improper heat treatment, or testing errors.

Overburning

Definition: Microstructural damage from excessive heating.

Main Causes:Temperature overshoots, faulty equipment, or improper furnace loading.

Casting Inclusions

Definition: Embedded foreign particles weakening the structure.

Main Causes:Impure materials, contaminated melting, or inadequate casting/rolling.

Summary

Aluminum defects arise from diverse causes but can be mitigated through optimized processes, stringent controls, and high-quality materials. Tailored solutions are essential for addressing specific defect types.