5 Ways to Tell if Aluminum is Anodized

How to distinguish if aluminum is anodized or not seems difficult for non-professionals to do, they look too similar, whether it is mill finished aluminum, anodized aluminum or painted aluminum. So, today let me use 5 ways to distinguish them, let's get started.

Appearance observation

Color contrast

- Anodized aluminum: Available in a variety of colors such as silver, black, gray, champagne, etc., with uniform color and a matte surface.

- Non-Anodized mill finished aluminum: is a single metallic silver-white color.

- Painted aluminum: Available in a variety of colors, but color uniformity and durability may vary depending on the coating process.

Glossiness

- Anodized aluminum: The surface is matte because the porous structure of the oxide film absorbs light.

- Non-Anodized mill finished aluminum: The surface is smooth and has a strong metallic luster.

- Painted aluminum: can achieve high gloss or matte effects.

Surface hardness test method

Hardness tester measurement

- Anodized aluminum: hardness 150-300HV;

- Mill finished and non-anodized aluminum: hardness is 60-100HV.

- Painted aluminum: Mainly depends on the quality and thickness of the coating, the hardness is usually lower than anodized aluminum.

Scratch test

- Anodized aluminum: shallow scratches, not easy to damage;

- Mill finished and non-anodized aluminum: easy to leave obvious scratches

- Painted aluminum: Usually not as resistant to wear and scratching as anodized aluminum

Eddy current thickness measurement

- Anodized aluminum: oxide film thickness: 5-30μm;

- Mill finished non-Anodized aluminum: no oxide film, thickness is close to zero.

Corrosion resistance test method

Salt spray test

In a neutral salt spray test conducted according to GB/T 10125-2012, no obvious corrosion spots or marks will appear on the surface of anodized aluminum after a certain period of time, while ordinary aluminum will corrode faster.

The corrosion resistance of painted aluminum depends on the integrity and quality of the coating. If the coating is damaged, the aluminum may corrode and is generally not as corrosion resistant as anodized aluminum.

Copper Accelerated Acetic Acid Salt Spray Test (CASS Test)

According to GB/T 12967.3-2008 standard, the protection level of anodized aluminum should reach or exceed level 9 after 48 hours of CASS test, while ordinary aluminum cannot reach this level.

Electrochemical testing method

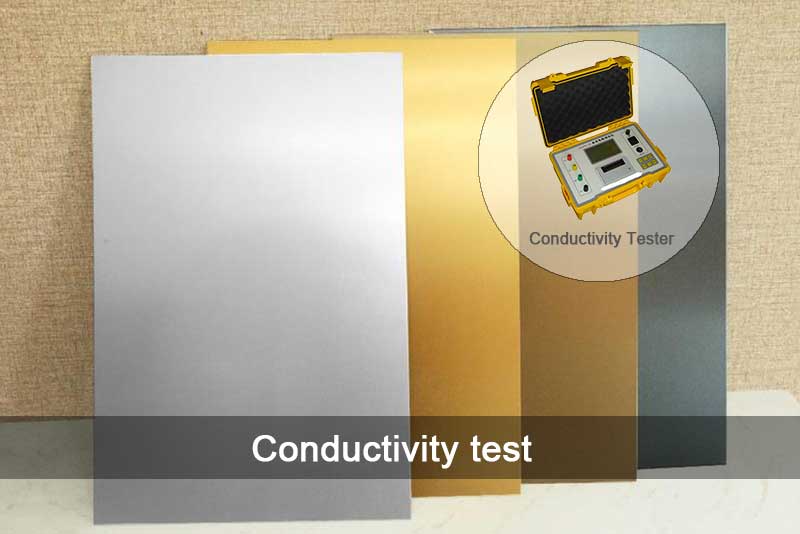

Conductivity test

The surface oxide film of anodized aluminum is insulating and has low electrical conductivity. Usually, the breakdown voltage of 1μm is about 30V, and after varnishing, the insulation resistance can reach 50-100MΩ.

Painted aluminum has a very low conductivity due to the presence of a paint film on its surface.

Ordinary aluminum has good electrical conductivity and high electrical conductivity.

Polarization curve test

The polarization curve was measured by an electrochemical workstation and the self-corrosion potential of anodized aluminum was more positive and the corrosion current density was smaller, showing better corrosion resistance.

Summarize

Anodized aluminum is anodized to improve its surface hardness and corrosion resistance, while also providing it with a wide range of color options and a lower surface gloss.

These properties give it broad application prospects in fields such as construction, electronics and automobiles.