Aluminum Jacketing Installation Guide

We will take aluminum insulation jacketing as an example to introduce the metal jacketing installation guide

Insulation material selection

It is crucial to choose the right insulation material for different types of fluid media and pipeline temperatures:

- Normal temperature water pipes: Rubber-plastic or PEF materials are recommended.

- Heating pipes (temperature≤100°C): Polyurethane is the first choice because of its low thermal conductivity and long service life, although the cost is higher.

- Steam pipes: Rock wool, glass wool or silicate materials are economical and widely used options.

- High temperature pipes (such as thermal oil pipes for industrial equipment): Aluminum silicate insulation materials should be selected to cope with extreme temperatures.

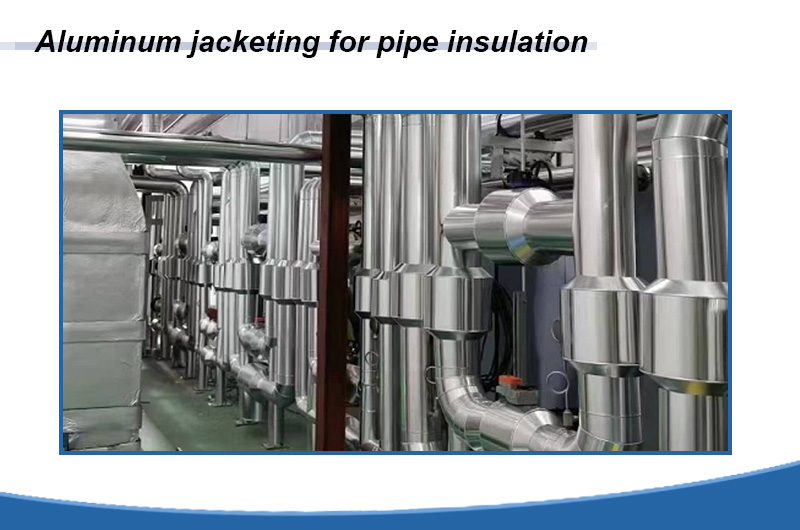

The role of aluminum jacketing

The main role of aluminum jacketing is to protect the internal insulation material from environmental factors such as seasonal changes and external damage, thereby extending the service life of the insulation material.

- 0.5mm thick aluminum jacketing, for pipes or equipment with an outer diameter of Φ≤426mm

- 0.8mm thick aluminum jacketing, for pipes or equipment with an outer diameter of Φ>426mm

- 1mm thick aluminum jacketing, for pipes or equipment with an outer diameter of Φ>2000mm

Preparation before installation

Before starting installation, make sure the following preparations have been completed:

Material preparation

- Aluminum jacketing: Make sure there is a warranty and quality inspection report, no oxidation spots, and the size error is ≤1mm.

- Angle guard: Use L-shaped multi-folding edge shaped angle guard.

Machinery and tools

Required machinery

- Shearing machine: 1 unit, can shear 4mm thick and 2.5m wide plates.

- Angle steel coiling machine: 1 unit, 1400 rpm, suitable for 40×40×4mm angle steel.

- Beading machine: 2 units.

- Rolling and marking machine: 2 units, two models.

- Combined angle bite machine: 1 set.

- Rolling machine: 2 sets.

- Corrugated board cutting machine: 1 set.

Hand tools

Rolling machine, edge press (electric or manual), hand drill, scissors, rivet gun, ruler, angle ruler, compass, drill bit, rivet or screw, mobile wire, nylon braid, etc.

Personnel arrangement

Equipped with professionally trained construction personnel to ensure installation quality and safety.

Precautions

Size requirements

The outer circumference of the straight pipe section Aluminum jacketing is 30~50mm larger than the insulation layer.

One end of the circumferential overlap is pressed out with ribs, and the longitudinal overlap of large-diameter pipes also needs to be pressed with ribs.

The size of the circumferential overlap of the straight pipe section is≥50mm.

Equipment insulation

Arrange the panels according to the equipment shape, stagger the seams and ribs, and leave a 50mm margin.

When cutting aluminum jacketing, its maximum length should be less than 1000mm. If it is too long, press out the diagonal line.

Cut to size

After the boards are arranged and splicedaccording to the equipment shape and the size of the corrugated board, they are cut with a corrugated board cutting machine. Flame cutting is prohibited.

Overlap and fixation

Overlap dimensions of aluminum jacketing for elbows and straight pipe sections:

- High-temperature pipes with a diameter more than 250mm: 75mm.

- Medium and low-pressure pipes: 50mm.

- Expansion area: more than 50mm.

Dimensions in open air or humid environments:

- Overlap dimensions more than 50mm

- Expansion area more than 75mm

Note: It is prohibited to fix at the overlap area.

Installation process

Let us introduce each step of the Aluminum insulation jacketing installation in detail as follows:

Process Overview

- Measurement and calculation

- Rolling and hemming

- Assembly

- Pipe wrapping (insulation layer)

- Self-tapping screw fixation

- Special part treatment

- Quality inspection

- Safety and maintenance

Step 1: Cutting to size

The aluminum roll jacketing is cut according to the outer circumference of the pipe insulation layer plus the overlap length of 30-50mm.

For large-diameter pipes, the longitudinal overlap of the aluminum jacketing also needs to be pressed out with ribs.

Step 2: Rolling and hemming

Use a rolling machine and a hemming machine to form the aluminum jacketing in the circumferential and transverse directions.

Step 3: Wrap and fix the aluminum jacketing

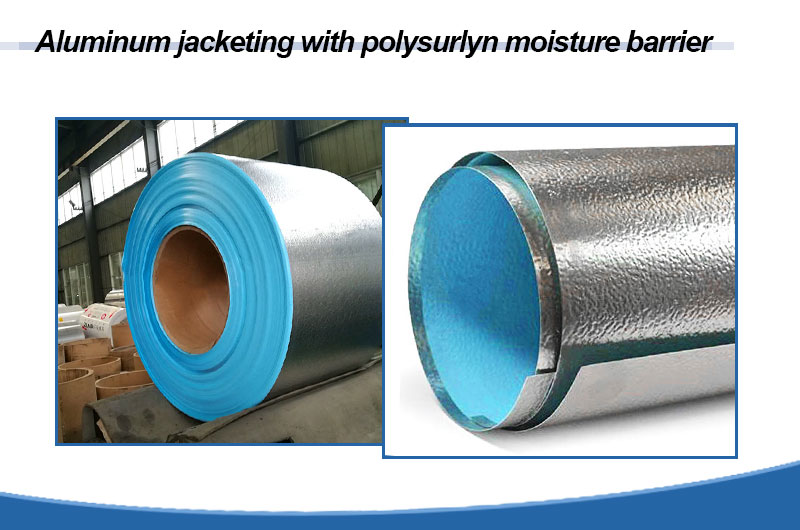

- Put the formed aluminum jacketing close to the moisture-proof layer to ensure that there is no looseness or overhead.

- Make sure that the joint is on the negative side.

- All cutting and punching positions ensure the integrity of the waterproof layer, and install waterproof boards at the disconnection points.

- Use 4×12 galvanized self-tapping screws for fixing, with a spacing of 200mm, and no less than 4 screws per channel.

Step 4: Special parts treatment

Elbow:

- Outer diameter less than 200mm: can be made into a right-angle elbow.

- Outer diameter more than 200mm: should be made into a segmented elbow.

- The longitudinal interface adopts the nail buckle form, and no less than 2 screws are fixed on each segment; the circumferential interface is processed with ribs on each piece, and the overlap width is 300~500mm.

Flange:

- Horizontal pipeline: circumferential ribs are pressed and sealed with circular rings.

- Vertical pipeline: the end face is smoothed into a 10°~20° cone shape.

Tee:

- The intersection of the branch pipe and the main pipe is turned over and fixed, and overlapped along the water.

- When the vertical pipe intersects with the horizontal straight pipe, the vertical pipe is wrapped first, and then the horizontal pipe.

Valve:

Refer to flange construction.

Step 5: Quality inspection

Appearance:

- No looseness, flange, warping, obvious pits.

- No backwater or gaps in the overlap layer.

- The longitudinal joint is parallel to the pipeline axis, and the circumferential joint is perpendicular to the pipeline axis.

- The joint is consistent with the slope.

- Ovality ≤8mm.

Flatness:The allowable error of aluminum jacketing is not more than 2mm/m, and the corrugated board is not more than 2.5mm/m.

Edge rolling:The edges of aluminum jacketing are neat, and both the circumferential and transverse directions need to be rolled.

Fixed:The self-tapping screws or rivets are firmly fixed with consistent spacing. According to actual needs, it is best to set anti-slip support every 3 meters.

Special molding:For flanges and reducers with a pipe diameter greater than DN32, they should be made into a "large and small head" shape to ensure that the whole is firm and reliable.

Overlap size:

- Equipment and pipelines: ≥20mm, expansion ≥50mm.

- Open air or humid environment: ≥50mm, expansion ≥75mm.

- High temperature pipe (≥250mm): straight pipe section and elbow aluminum jacketing overlap ≥75mm.

- Flat wall of equipment: plug-in size ≥30mm.

Step 6: Safety and maintenance

Ensure construction safety, protect the integrity of the insulation layer and waterproof layer, and avoid man-made damage.

Take temporary protective measures for unavoidable trampling areas.

Key points of quality control

In order to ensure the quality of installation, the following points should be noted:

Horizontal pipe:Circumferential joints follow the slope direction, and the circumferential overlap faces the lower part. The longitudinal joint is 15°~45° below the horizontal center line, and the seam faces downward. When there are obstacles, the longitudinal joint can be moved to within 60°above the horizontal center line of the pipe.

Vertical pipe:Lay from bottom to top to form a water-following joint.

Vertical equipment:Fixed on the support in sections.

Flat top of equipment:Install according to the designed slope.

Corrugated board:Install the bottom support first, then install from bottom to top, fix with bolts with rubber pads or blind rivets, with narrow waves facing outward.

Expansion circumferential joint:Meet the thermal expansion requirements, without fixings, to form a movable joint.

Circumferential movable joint spacing:

- Medium temperature is less than or equal to 100°C: not specified.

- Medium temperature from 101°C to 320°C: 4m - 6m

- Medium temperature greater than 320°C: 3m - 4m.

Summary

This aluminum insulation jacketing installation guide is also applicable to other metal jacketing installations, and the installation methods are similar.

Aluminum insulation jacketing installation is a technically challenging job that requires you to be serious and patient. Relax and make it more interesting!