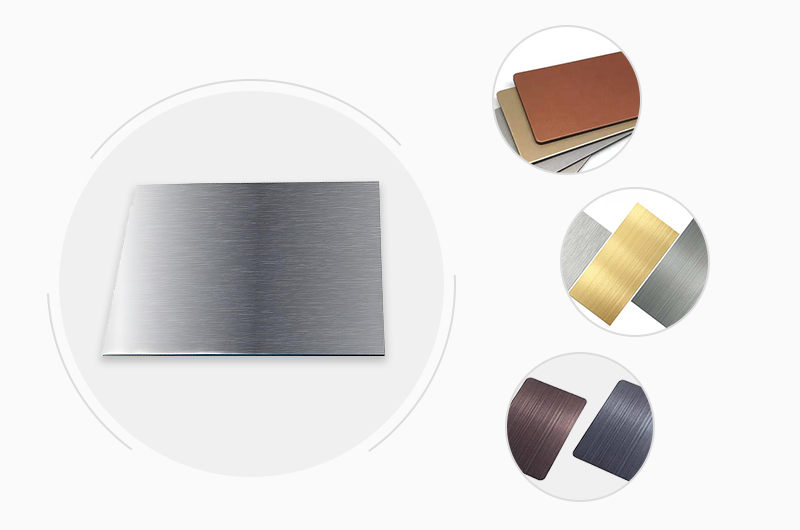

Brushed Aluminum Sheet

Brushed aluminum sheet is a type of aluminum sheet that has undergone a special surface treatment process to create a distinctive brushed texture, enhancing its metallic appearance and feel.

Worthwill's brushed aluminum sheet is a good choice due to its premium quality, advanced technology, and a wide range of products that meet various customer needs.

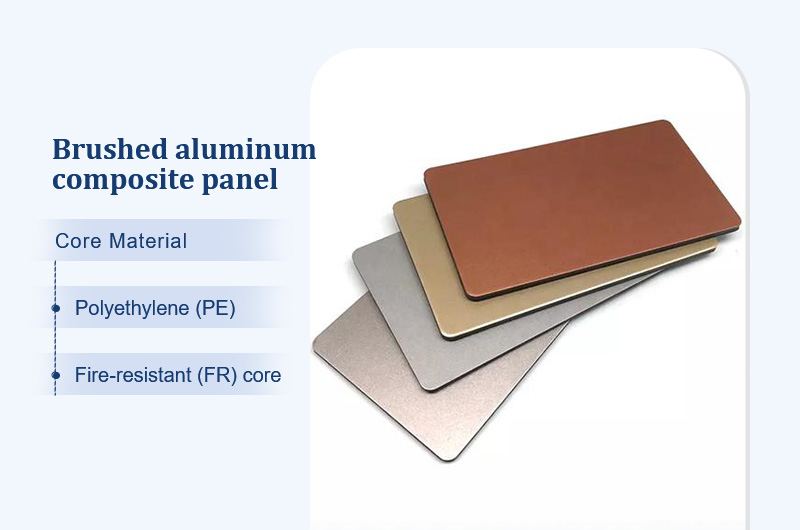

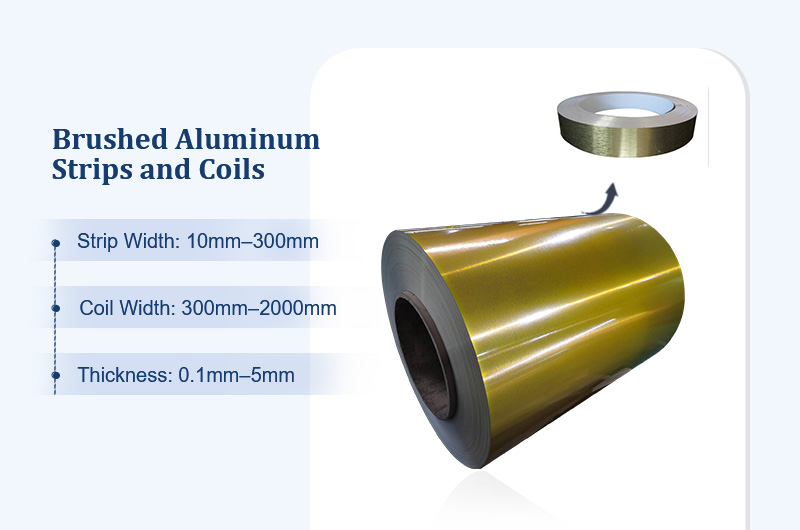

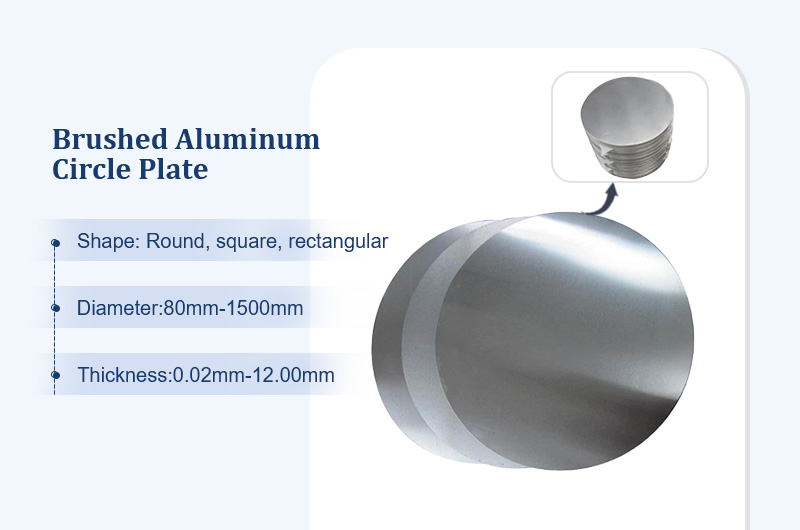

- Product Type:

- Sheet, Coil, Composite Panel, Round Plate.

- Alloy:

- 1060, 1050, 1100, 3003, 3004, 3A21, 5052, 5005, 5083, 5A05, 6061 etc.

- Thickness:

- 0.1mm - 12.0 mm.

- Width:

- 30mm – 1,900mm.

- Texture Type:

- Linear brushing, random brushing, wave brushing, spiral brushing, thread brushing, cross brushing.

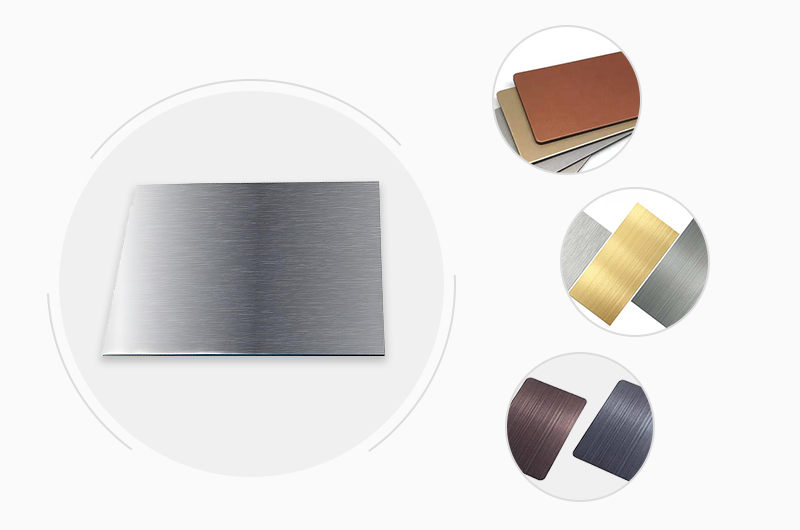

- Colors:

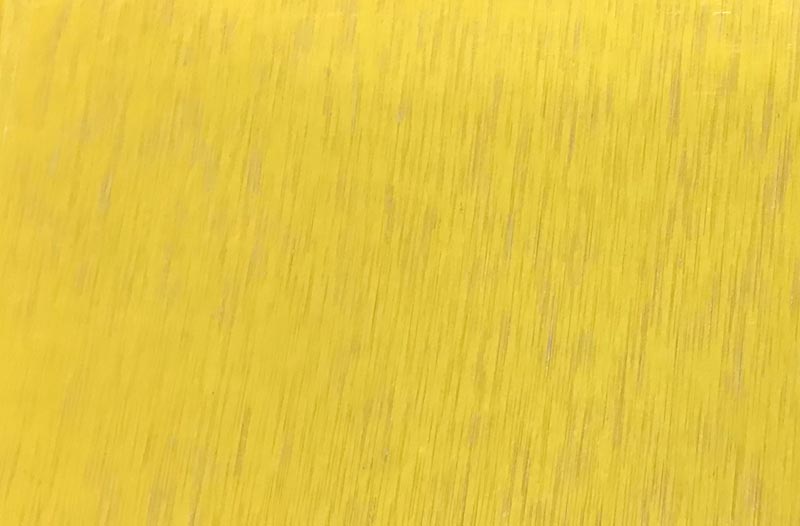

- Gold, silver, regal blue, regal red, terra cotta, matte black, sandstone almond, regal white, medium bronze, mansard brown, etc.

- Common Thickness:

- 1/4", 1/8", .040".

- Common Standard Sizes:

- 1220mm x 2440mm (4' x 8').

Brushed Aluminum Sheets Overview

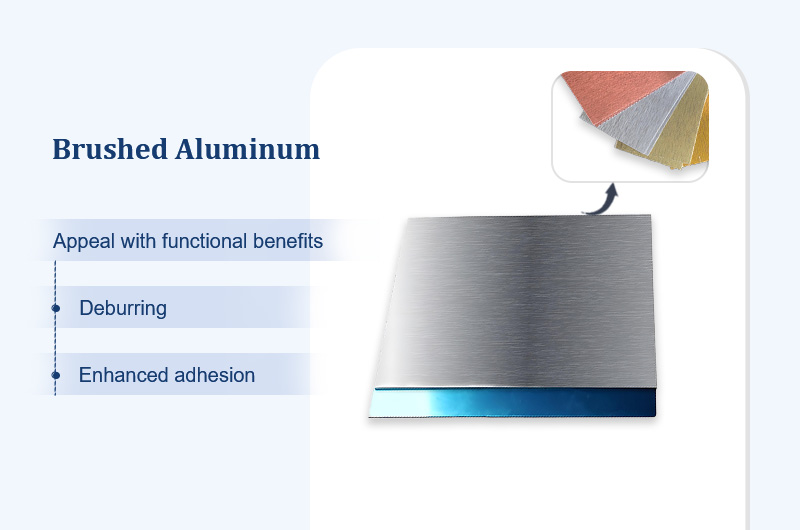

What is the Brushed Aluminum Sheet?

The aluminum sheet with a matte surface finish achieved through mechanical grinding or belt grinding processes to create unidirectional or cross-directional textures, combining both decorative appeal and functional advantages (such as deburring and enhanced adhesion).

Brushed Aluminum Sheet Textures

- Linear Brushing: Parallel straight lines.

- Random Brushing: Irregular, non-directional patterns.

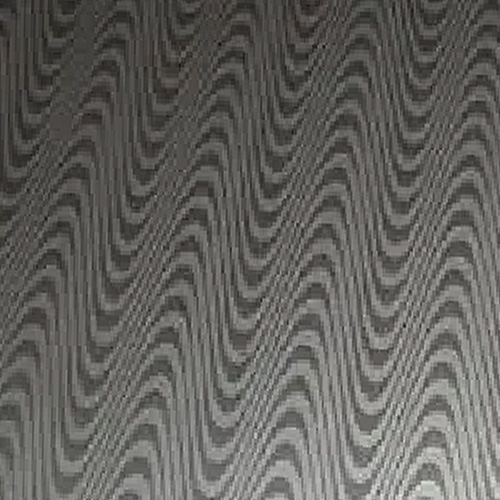

- Wave Brushing: Wavy texture for visual depth.

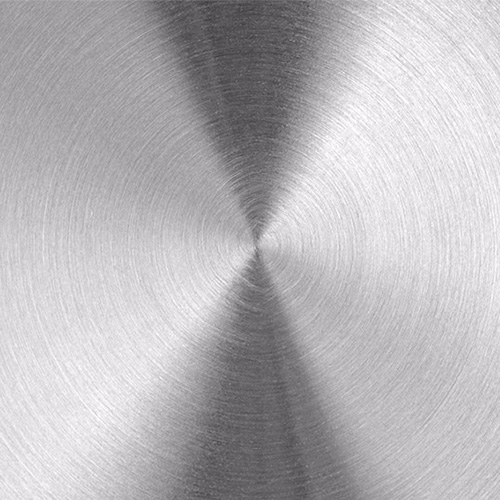

- Circular/Spiral Brushing: Rotational or spiral patterns for decorative accents.

- Thread Brushing: Fine linear grooves.

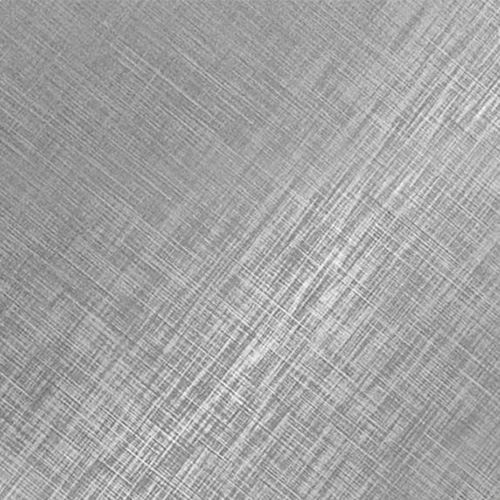

- Cross Brushing: Perpendicular or crisscross textures.

Features & Benefits

- Matte Finish: Reduces glare, ideal for premium designs.

- Scratch Resistance: High surface hardness minimizes daily wear marks.

- Weather Resistance: Suitable for indoor/outdoor use; coating lifespan exceeds 5 years.

- Low Maintenance: Easily cleaned with neutral detergents.

Brushed Sheets Texture and Colors

Brushed Aluminum Texture

Linear Brushing

Random Brushing

Wave Brushing

Circular/Spiral Brushing

Thread Brushing

Cross Brushing

Colors and Coatings

Regal White

Reflective White

Warm White

Pearl Gray

Desert Sand

Surrey Beige

Slate Gray

Royal Blue

Terra Cotta

Cypress Green

Dark Bronze

Brite Red

Charcoal

Midnight Black

Galvalume

Coatings

- Polyester (PE): Cost-effective, vibrant colors; indoor use (5–7 years outdoor).

- High-Density Polyester (HDP): Superior UV/abrasion resistance (8–10 years outdoor).

- PVDF: Extreme corrosion/UV resistance (>20 years outdoor).

Colors

- Standard: Metallic silver, champagne gold, space gray, matte black.

- Custom: Pantone or RAL color matching.

Brushed Aluminum Sheets in Stock

We have a large stock of brushed aluminum sheet and coil, with thickness ranging from 0.1mm to 10mm, and we can also cut it into the sizes you need.

4x8 brushed aluminum sheet

4x8 brushed aluminum sheet

1/4" brushed aluminum sheet

1/4" brushed aluminum sheet

1/8" brushed aluminum sheet

1/8" brushed aluminum sheet

.040 brushed aluminum sheet

.040 brushed aluminum sheet

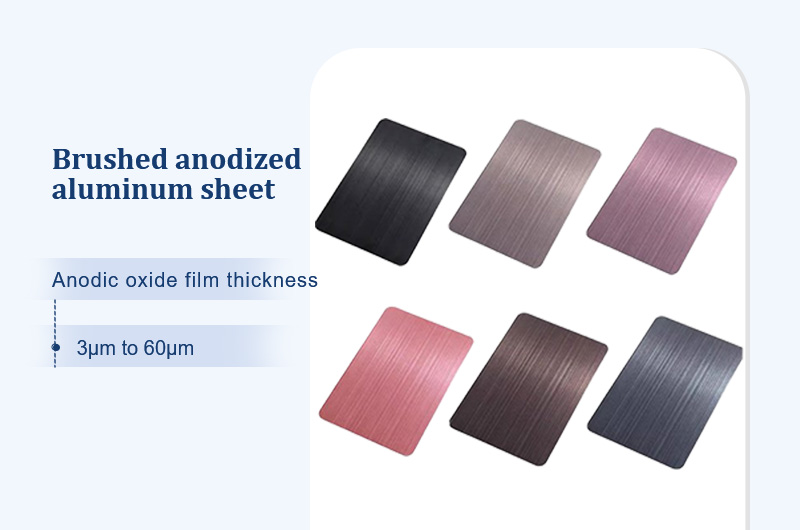

In addition, we also support other processes such as anodizing, color coating, and surface laminating.

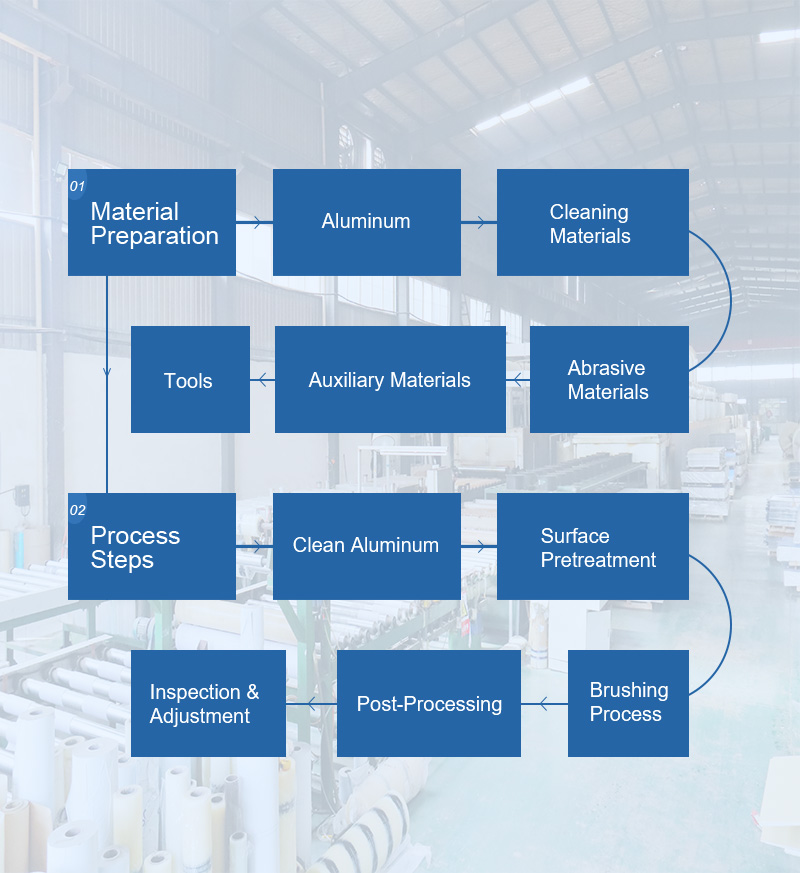

How to Achieve a Brushed Finish on Aluminum

Step 1: Material Preparation

- Aluminum: Select suitable brushed aluminum material.

- Cleaning Materials: Detergent, non-abrasive cloth/soft brush.

- Abrasive Materials: Sandpaper (60–240 grit), abrasive brushes (nylon, sisal, brass).

- Auxiliary Materials: Masking tape, transparent coating/sealant.

- Tools: Grinder/hand brush, clamps, polishing cloth.

Step 2: Process Steps

- Clean Aluminum: Remove dirt with detergent.

- Surface Pretreatment: Polish with fine sandpaper to eliminate scratches.

-

Brushing Process:

- Secure aluminum to prevent movement.

- Brush unidirectionally with consistent pressure.

- Adjust force/angle as needed; repeat.

-

Post-Processing:

- Remove edge burrs.

- Polish for enhanced finish.

- Apply protective coating.

- Inspection & Adjustment: Check texture uniformity; refine locally if needed.

Tips: Maintain consistent pressure, avoid warping, test parameters.

Brushing Equipment Selection

- Small-Scale/Precision: Handheld electric brushes, narrow belt sanders.

- Large-Scale/Batch: Roller brush machines, wide abrasive belt systems.

- Complex Textures: CNC brushing machines for custom patterns.

- Material-Specific: Soft metal-compatible tools to prevent surface damage.

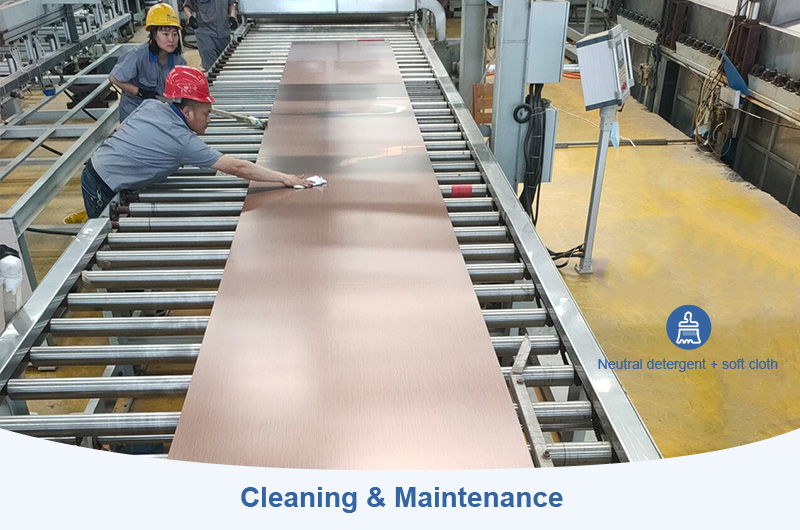

Cleaning and Maintenance

- Routine: Neutral detergent + soft cloth.

- Stubborn Stains: Diluted white vinegar (1:1).

- Oxidation: Metal polish for luster restoration.

Application

- Wall cladding.

- Window/door.

- Frames and Facades. .

- Trims and Molding.

- Furniture Components.

- Accessories.

- Light Fixtures.

- Decorative Panels and Artwork.

- Indoor and Outdoor Signage.

- Nameplates and Badges.

- Device Casings.

- Appliances.

- Machine Parts and Panels.

- Edge Blending and Deburring.

- Car Components.

- Wheels and Rims.

Frequently Asked Questions

Brushed vs. Regular Aluminum?

Brushed has matte texture, scratch resistance, and decorative appeal; regular aluminum is semi-glossy and lower cost.

Durability?

5–8+ years lifespan; PVDF coatings extend outdoor performance.

Cleaning Tips?

Use soft cloths; avoid abrasive tools.

Partial Brushing Possible?

Yes—multi-angle brushing adds visual depth.

Brushed vs. Satin Finish?

Brushed has distinct texture; satin offers subtle gloss.

Are you a brushed aluminum sheets manufacturer or a wholesaler?

We are 100% factory for brushed aluminum sheets, you can visit the factory at any time, or check the factory online through VR.

Why Choose Worthwill’s Brushed Aluminum?

Choose Worthwill's brushed aluminum sheet/plate for its exquisite appearance and high quality, which are achieved through advanced manufacturing processes and strict quality control. The plate's excellent durability and wide range of applications make it a reliable choice that meets the diverse needs of customers, ensuring their satisfaction.

- Technical Edge: High-precision CNC processing for uniform textures.

- Efficiency: Scalable production from prototypes to bulk orders.

- Customization: Tailored textures, small-batch support.

- Material Range: 1000–7000 series aluminum alloys.

- Sustainability: RoHS compliance, closed-loop anodizing wastewater treatment.

Something you might be interested in

You may be interested in some other information about Brushed Aluminum Sheet