Aluminum Gutter Coil

Aluminum gutter coil is a type of color-coated aluminum, which is mainly used in rainwater collection and guidance systems in construction projects. It plays a very critical role in the overall construction.

- Alloy:

-

- 3003

- 3105

- Temper:

-

- H24

- H26

- H44

- H46

- Width:

-

- 5”

- 6”

- 11.75”

- 15”

- Thickness:

-

- .027

- .032

- Coating:

-

- PE

- PVDF

- HDPE

- Epoxy

Excellent Performance

We use high-quality 3003, 3105 aluminum-manganese alloy aluminum to produce gutter coils, which will not crack when bent, are rust-proof, corrosion-resistant and durable.

Specification

- Alloy: 3003, 3105

- Temper: H24, H26, H44, H46

- Width: 5”, 6”, 11.75”, 15” or customized, from 3.94” to 59.06”.

- Thickness: .027 Guage, .032 Guage or customized, from .0118 in to .0394 in.

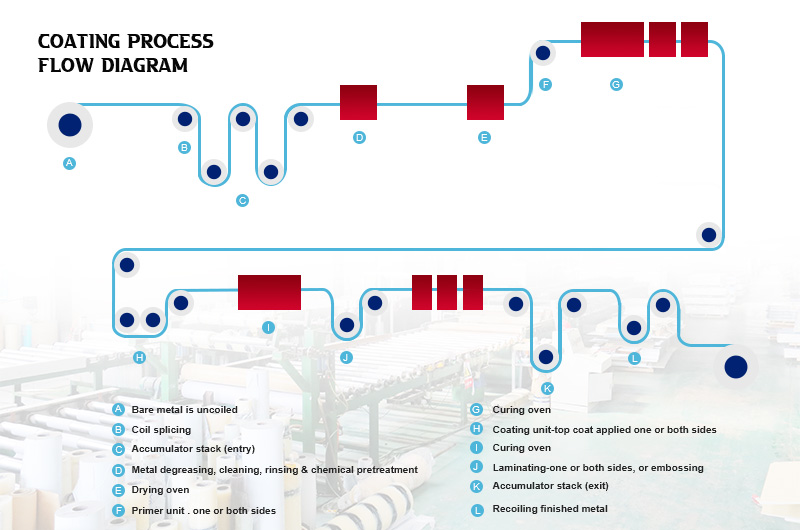

At present, the paints we produce for gutter coils include polyester(PE) , high weather-resistant polyester(HDPE) , and fluorocarbon(PVDF) .

Support 1 side painted and 2 side painted

Advantages

- Easy Installation

- Easy Maintenance

- Rust and corrosion resistance

- Light Weight

PE VS HDPE VS PVDF

The problem of inconsistent color of aluminum gutter coil is mainly due to coating. Let's explore the difference between PE, PVDF and HDPE paint.

| Item | PE | HDPE | PVDF |

|---|---|---|---|

| Applied aluminum thickness | 0.01mm - 10mm | 0.2mm - 10 mm | 1.5mm - 10mm |

| Coating thickness | 16 μm - 25 μm | 20 μm - 25 μm | More than 25 μm |

| Usage | Interior | Interior and exterior | Exterior |

| Cost | Low | Middle | High |

| Use life | 6 - 8 years | 10 years | 15 - 20 years |

Basic Materials

3003 and 3105 aluminum alloys are perfect materials for gutter aluminum coils, rust-proof, corrosion-resistant, easy to install and easy to process.

| 3003 ALLOY CONTENT | |||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | / | / | 0.1 | / | 0.15 | Remain |

| 3003 MECHANICAL PROPERTIES | |||||||||

| temper | Thickness (inch) | Tensile Strength | Yield Strength | Elongation ( min %) | |||||

| Min (ksi) | Max (ksi) | Min (ksi) | Max (ksi) | ||||||

| H12 OR H22 | 0.017-0.031 | 16 | 22 | 11 | / | 4 | |||

| 0.032-0.050 | 16 | 22 | 11 | / | 5 | ||||

| 0.051-0.113 | 16 | 22 | 11 | / | 6 | ||||

| 0.114-0.161 | 16 | 22 | 11 | / | 7 | ||||

| 0.162-0.249 | 16 | 22 | 11 | / | 8 | ||||

| 0.250-0.499 | 16 | 22 | 11 | / | 9 | ||||

| 0.500-2.000 | 17 | 23 | 12 | / | 10 | ||||

|

H14 or H24 |

0.009-0.012 | 19 | 25 | 16 | / | 1 | |||

| 0.013-0.019 | 19 | 25 | 16 | / | 2 | ||||

| 0.020-0.030 | 19 | 25 | 16 | / | 3 | ||||

| 0.032-0.050 | 19 | 25 | 16 | / | 4 | ||||

| 0.051-0.113 | 19 | 25 | 16 | / | 5 | ||||

| 0.114-0.161 | 19 | 25 | 16 | / | 6 | ||||

| 0.162-0.249 | 19 | 25 | 16 | / | 7 | ||||

| 0.250-0.499 | 19 | 25 | 16 | / | 8 | ||||

| 0.500-1.000 | 20 | 26 | 17 | / | 10 | ||||

|

H16 OR H26 |

0.006-0.019 | 23 | 29 | 20 | / | 1 | |||

| 0.020-0.031 | 23 | 29 | 20 | / | 2 | ||||

| 0.032-0.050 | 23 | 29 | 20 | / | 3 | ||||

| 0.051-0.162 | 23 | 29 | 20 | / | 4 | ||||

| 3105 ALLOY CONTENT | |||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | 0.4 | 0.1 | 0.15 | Remain |

| 3105 MECHANICAL PROPERTIES | |||||||||

| Temper | Thickness (inch) | Tensile Strength | Yield Strength | Elongation(min %) | |||||

| Min (ksi) | Max (ksi) | Min (ksi) | Max (ksi) | ||||||

| H12 | 0.017-0.019 | 19 | 26 | 15 | / | 1 | |||

| 0.020-0.031 | 19 | 26 | 15 | / | 1 | ||||

| 0.032-0.050 | 19 | 26 | 15 | / | 2 | ||||

| 0.051-0.080 | 19 | 26 | 15 | / | 3 | ||||

| H14 | 0.013-0.019 | 22 | 29 | 18 | / | 1 | |||

| 0.020-0.031 | 22 | 29 | 18 | / | 1 | ||||

| 0.032-0.050 | 22 | 29 | 18 | / | 2 | ||||

| 0.051-0.080 | 22 | 29 | 18 | / | 2 | ||||

| H16 | 0.013-0.031 | 25 | 32 | 21 | / | 1 | |||

| 0.032-0.050 | 25 | 32 | 21 | / | 2 | ||||

| 0.051-0.080 | 25 | 32 | 21 | / | 2 | ||||

| H22 | 0.013-0.019 | 19 | / | 15 | / | 3 | |||

| 0.020-0.031 | 19 | / | 15 | / | 4 | ||||

| 0.032-0.050 | 19 | / | 15 | / | 5 | ||||

| 0.051-0.080 | 19 | / | 15 | / | 6 | ||||

| H24 | 0.013-0.019 | 22 | / | 18 | / | 2 | |||

| 0.020-0.031 | 22 | / | 18 | / | 3 | ||||

| 0.032-0.050 | 22 | / | 18 | / | 4 | ||||

| 0.051-0.080 | 22 | / | 21 | / | 6 | ||||

| H26 | 0.013-0.031 | 25 | / | 21 | / | 3 | |||

| 0.032-0.050 | 25 | / | 21 | / | 4 | ||||

| 0.051-0.080 | 25 | / | 21 | / | 5 | ||||

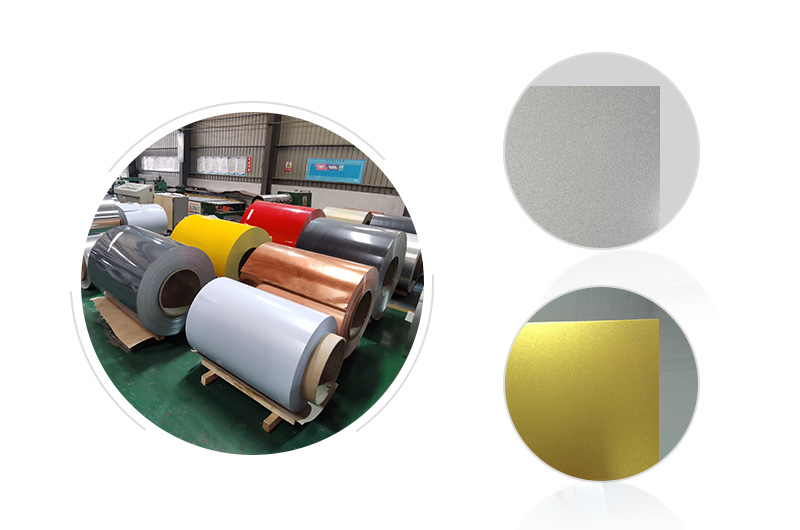

Gutter Coil Color Chart

Worthwill is one of the few single-source gutter coil manufacturers with an in-house paint line and roller coating line.

10 Musket Brown

80 White

Al Almond

Antique Ivory

Black

Charcoal Gray

Chestnut Tan

Classic Cream

Clay

Copper

Coppertone

Dark Gray

Granite Gray

Grecian Green

Heritage Blue

Herringbone

Linen

Mill Finish

Nor Beige

Nor Gray

Nor Pewter

Pacific Blue

Pearl Gray

Pebblestone Clay

Royal Brown

Sand Castle

Scotch Red

Silver Gray

Terratone

Tuxedo Gray

Wicker

30 Musket Br.

30 White

Beaver Brown

Buckskin

Burgundy

Champagne

Copper Penny

Dark Bronze

Designer Copper

Forest Green

French Cream

Imperial Brown

Montana Suede

Tudor Brown

Village Green

Aluminum Gutter Coil Stock

We have a large stock of gutter aluminum coils in different specifications, and can respond quickly to your delivery needs

2 SIDE PAINTED

PVDF coating

5” White aluminum gutter coil

1 SIDE PAINTED

PE coating

5” White aluminum gutter coil

2 SIDE PAINTED

PE coating

6” Black aluminum gutter coil

1 SIDE PAINTED

PVDF coating

6” Black aluminum gutter coil

Want to explore more?

Go hereSomething you might be interested in

You may be interested in some other information about gutter aluminum coils