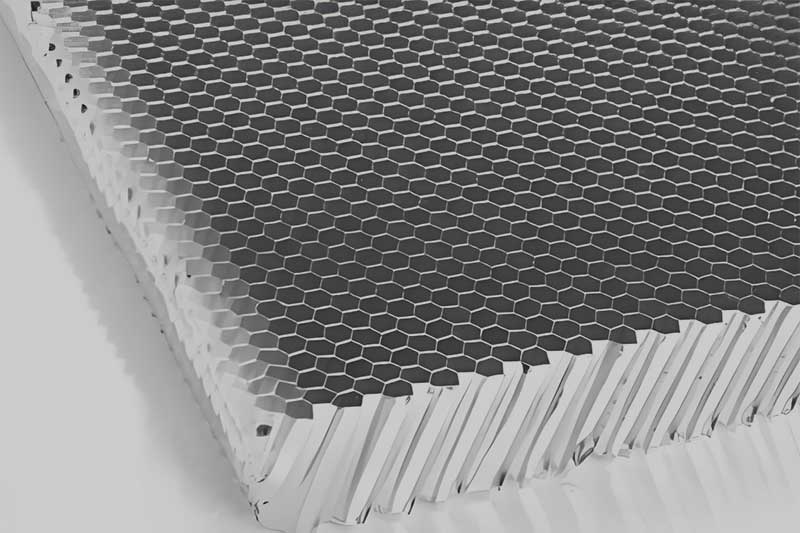

Aluminum Honeycomb Panels

Aluminum honeycomb panels adopt aluminum hexagonal honeycomb structure, low density, high strength, sound insulation, heat insulation, fire prevention . Flat surface, corrosion resistance, strong earthquake resistance.

- Alloy:

- 1100, 2024, 3003, 3005, 3103, 3104, 5052, 6063, 7075.

- Total Thickness:

- 0.125", 0.25", 0.375", 0.5", 4mm, 8mm, 10mm, 15mm,18mm, 25mm,32mm, or customize.

- Width:

- 1000mm, 1220mm, 1250mm, 1500mm, Max 2440mm.

- Length:

- 2440mm, 3000mm, 3500mm, 5800mm, or customize.

- Cell Size:

- 9.5mm/12.7mm, or customize.

- Honeycomb Core Wall Thickness:

- 0.02mm, 0.04mm, 0.05mm, 0.06mm, 0.08mm Max 0.12mm.

- Sise:

- 1/4”(6.35mm), 1/3”(8.47mm), 3/8”(9.53mm), 1/2”(12.7mm) , or customize.

What is The Aluminum Honeycomb Panel?

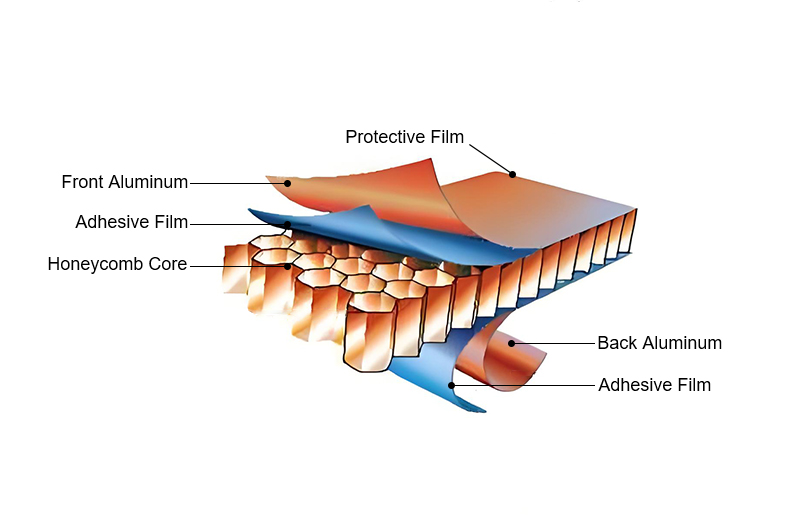

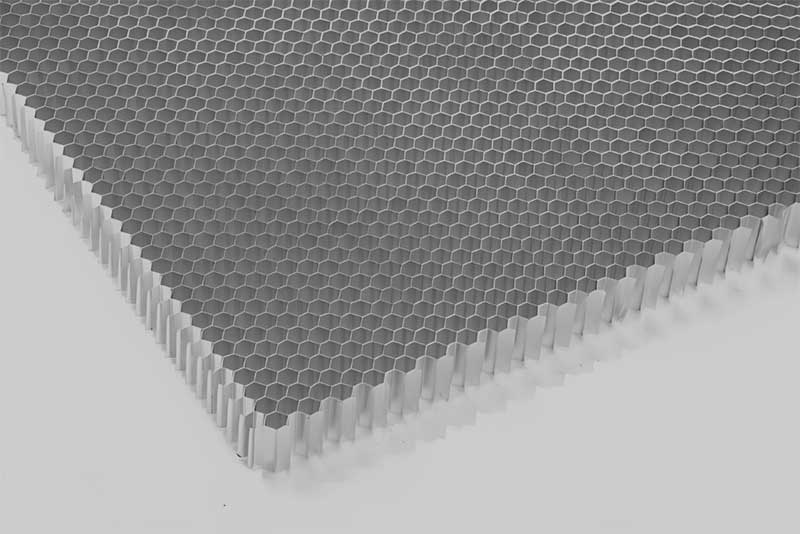

Honeycomb composite aluminum panel is a composite metal material composed of base plate, hexagonal honeycomb core and panel. These three materials are made by high temperature and high pressure compound manufacturing, which has the same structure as a sandwich, so it is also called Sandwich Panels.

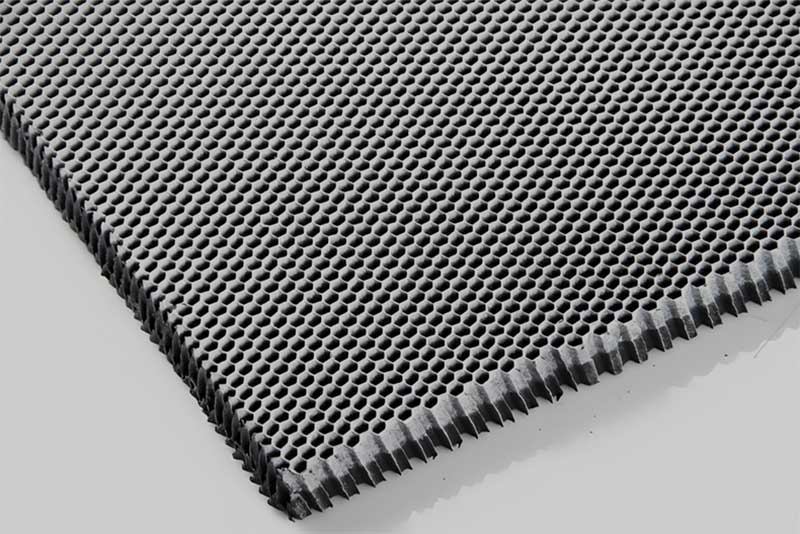

Aluminum honeycomb core material

Honeycomb structures are natural or man-made structures with a honeycomb geometry. Worthwill's honeycomb cores are made from 3003, 3005 or 5052 grade aluminum alloys; slices with tolerances up to ±0.125 mm and a minimum slice thickness of 3 mm.

- Alloy: 3003, 3005, 3103, 3104, 5052, 5056.

- Thickness: 0.045", 0.17", 0.245", 0.42", 0.55", 0.67", 0.92", customizable.

- Wall Thickness: 0.02mm, 0.04mm, 0.05mm, 0.06mm, 0.08mm, Max 0.12mm.

- Compressive Strength N/mm²: 1.22.

- Density Kg/m³: 25, 28.8, 76.9, 83, 96, or as per your requirement.

Front and Back Aluminum Sheet

- Alloy: 1100, 2024, 3003, 3014, 5005, 6063, 7075

- Thickness: 0.5mm, 0.6mm, 0.8mm, 1mm, 1.5mm, 3mm, or as per your requirement.

- Coating: PVDF, PE

- surface Treatment: Anodized, Mill Finished, Embossed, Mirror(polishing).

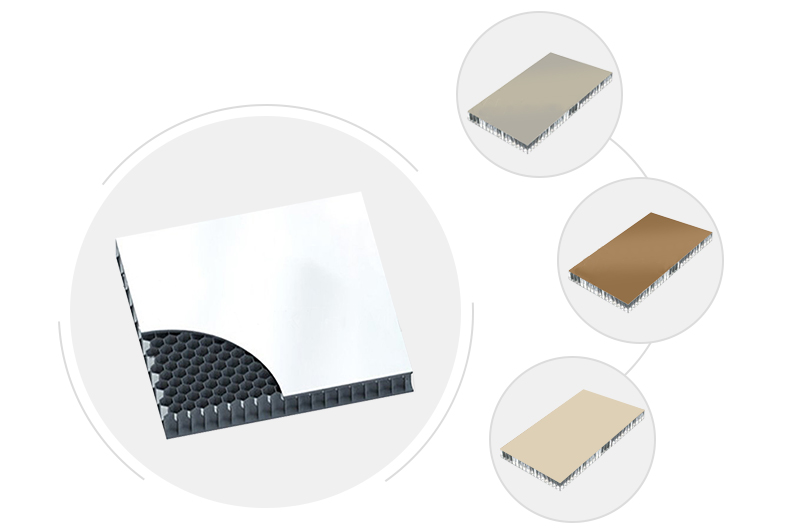

Type of Aluminum honeycomb Panel

- Flat Aluminum Honeycomb Panel (Open Edge)

- Closed Edge Aluminum Honeycomb Panel

- Boxed Aluminum Honeycomb Panel (with Brackets)

- Aluminum Honeycomb Panel with Embedded Profiles

- Curved Aluminum Honeycomb Panel (Open Edge)

Technical Parameters

| Property | Test Method | Test Result |

| Tensile Sterngth, Rm |

ASTM

E8/E8M-11 (Testing on top aluminium skin) |

159Mpa |

| Yield Strength Rp0.2 | 146Mpa | |

| Percentage Elongation after Fracture, A50mm | 17% | |

|

Coeffiecient

of Linear Thermal Expansion (1/℃) |

ASTM D696-08 | -30℃~30℃:29.89x10-6 |

| Core Shear Ultimate Strength | With reference to ASTM C393M-06 3points loading | 0.77Mpa |

| Peel Torque | With reference to ASTM D1781-98(2012) | 7.23mm·kgf/mm |

| Sound Transmission Loss (STC) | ASTM E90-09 | 19dB |

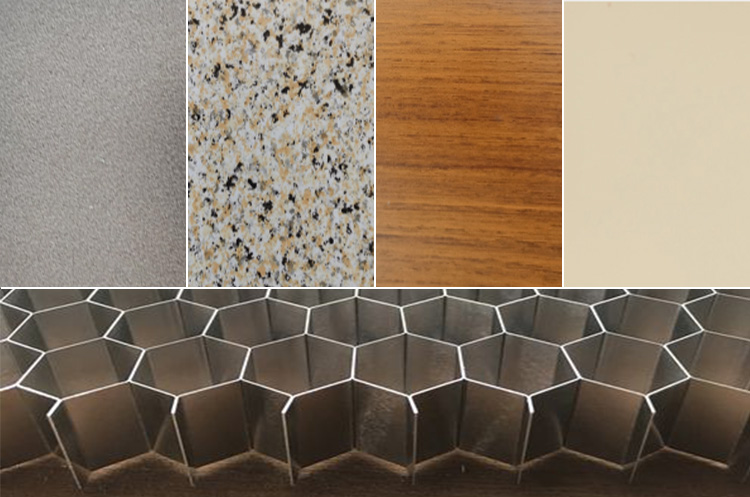

Color Chart of Front and Back Aluminum Sheet

Worthwill can customize the front and back sheet of aluminum honeycomb panels with different surface types according to your needs.

Solid Colors Series

Metallic Colors Series

Wood Grains Series

Stone Grains Series

Price of Aluminum Honeycomb Panel

Aluminum honeycomb panels are very cost-effective. Because they are lightweight, they reduce shipping and installation costs, while their durability minimizes maintenance and replacement costs. And we offer factory direct prices, which will save you money too. Click the button below to contact us, and we have a professional team to help you choose the right aluminum honeycomb panel.

Advantages and Benefits

The weight of honeycomb sandwich panels with the same rigidity is only 1/5 of that of aluminum panels and 1/10 of that of steel panels.

Various patterns and colors such as wood grain and stone grain can be made.

Good sound insulation and fire protection class FR A2+

simple to install and easy to disassemble, time-saving and labor-saving

Salt spray spraying for 48 hours without pinholes, cracks, or bubbles.

It does not emit any gases harmful to the human body, is non-radioactive and can be completely recycled.

Aluminum Honeycomb Panel Coating System(PPG)

DURANAR coating systems offer superior performance and long-lasting color. All DURANAR coatings contain fluoropolymer resins—chemically inert and protect your building from the stresses of the surrounding environment.

- Will not whiten or dent when exposed to salt spray.

- Resists chalking, fading, UV and alkaline degradation.

- Will not stain by mineral acids and cleaners.

- Excellent adhesion, film integrity and flexibility.

- Resists chipping, cracking, erosion, abrasion and impact.

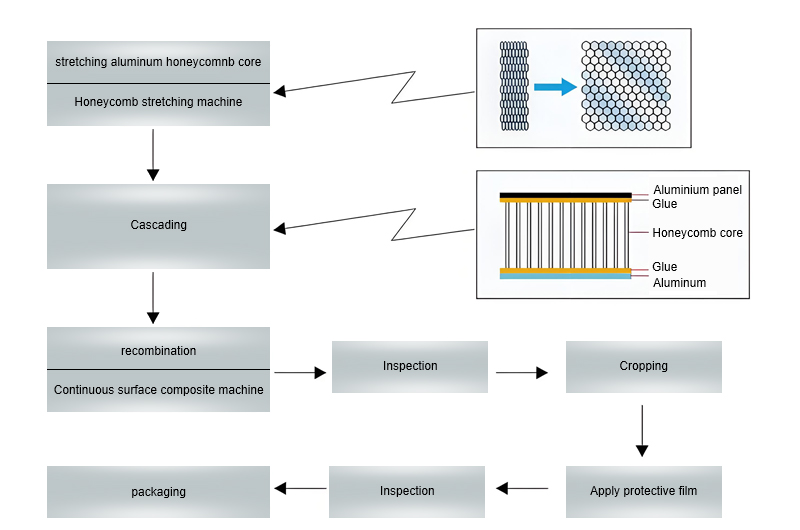

Production Process

Production process including honeycomb core and honeycomb panel

Production process of honeycomb core

The production of honeycomb core materials requires the use of professional manufacturing equipment, such as composite machines, glue coating machines, heating furnaces, coiling machines, etc. First, the honeycomb core material is pressed into a specified thickness, glued by a glue coating machine, pressed into a board, and finally cured and dried by a heating furnace.

- 1 Aluminum foil is folded into a honeycomb structure

- 2 Gluing and bonding

- 3 Hot pressing and curing

- 4 Core block cutting

- 5 Stretching or expanding

- 6 Surface treatment

- 7 Cutting and forming

Production process of honeycomb panel

- 1 Material preparation

- 2 Pretreatment of top and back sheet

- 3 Special glue coating

- 4 Pressing and molding like making a sandwich

- 5 Cutting and processing

Honeycomb Core and Honeycomb Panel for Sale

DURANAR coating systems offer superior performance and long-lasting color. All DURANAR coatings contain fluoropolymer resins—chemically inert and protect your building from the stresses of the surrounding environment.

The density of honeycomb aluminum core is 76.9kg/m³, made of 5052 or 3003 grade alloy, wall thickness from 0.06mm to 0.1mm.

- Size: 1250 x 625mm, 2500 x 1250mm

- Thickness: 10mm - 30mm

3.2mm (1/8") Cell Aluminium Honeycomb

The density of honeycomb aluminum core is 83kg/m³, made of 5052 or 3003 grade alloy, wall thickness from 0.08mm to 0.12mm.

- Size: 1250 x 625mm, 2500 x 1250mm

- Thickness: 10mm - 30mm

6.4mm (1/4") Cell Aluminium Honeycomb

The density of honeycomb aluminum core is 28.8kg/m³, made of 3003 grade alloy, wall thickness from 0.03mm to 0.05mm, use for larger sandwich panels.

- Size: 1250 x 625mm, 2500 x 1250mm

- Thickness: 10mm - 30mm

19.1mm (3/4") Cell Aluminium Honeycomb

- Size(mm): 1200 x 2400, 1400 x 3000, 1200 x 240, 1400 x 3000, 2000 x 6000

- Thickness: 1/8", 1/4", 3/8", 1/2", 3/4", 1"

12" x 12" aluminum honeycomb panel

- Size(mm): 1200 x 2400, 1400 x 3000, 1200 x 240, 1400 x 3000, 2000 x 6000

- Thickness: 1/8", 1/4", 3/8", 1/2", 3/4", 1"

24" x 24" aluminum honeycomb panel

- Size(mm): 1200 x 2400, 1400 x 3000, 1200 x 240, 1400 x 3000, 2000 x 6000

- Thickness: 1/8", 1/4", 3/8", 1/2", 3/4", 1"

24 x 48 inch aluminum honeycomb panel

Application of Aluminum Honeycomb Panel

Architecture

Honeycomb panels have a flat, rigid, stable structure and can be used as a backing material for metal, glass, stone and other decorative surfaces in buildings. Applications include wall cladding, ceilings, canopies and elevator interiors.

Advertising

Aluminum honeycomb panels are highly flat, easy to process, and can be customized with surface treatment, making them ideal materials for billboards and display panels. Their weather resistance and anti-corrosion properties also ensure long-term outdoor use.

Interior decoration

Aluminum honeycomb panels can be used for indoor wall, ceiling, partition and other decoration projects. Its diverse surface treatment and color selection can meet the decoration needs of various styles, and it also has the advantages of easy cleaning and durability.

Furniture

Aluminum honeycomb panels are also used in furniture manufacturing, such as office desks, cabinets, display racks, etc. Its lightness, durability, and beautiful appearance make the furniture more practical and fashionable.

Transportation

Honeycomb panels are widely used in the manufacture of vehicles such as automobiles and airplanes. They can be used in body structures, seats, floors, sound insulation, etc.

Shipbuilding

For ship interior panels and partitions, furniture, ceiling and floor panels, hulls and bulkheads, doors, etc.

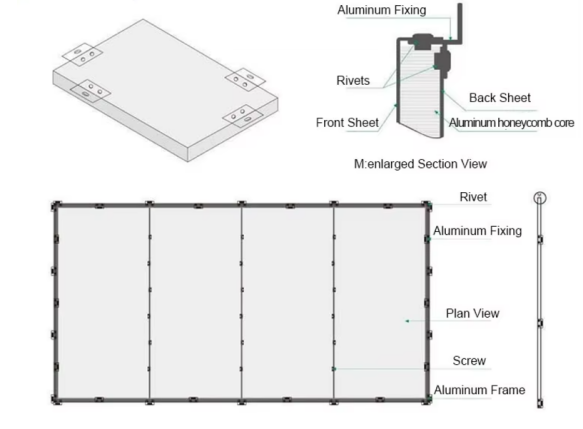

Installation Guide

We have a professional installation technical team of 12 people, who have guided or directly participated in the installation of hundreds of honeycomb aluminum panels. If you have any questions about the installation of honeycomb aluminum panels, please contact us and we will provide free technical support.

Why Choose Us

Worthwill is a professional manufacturer and supplier of honeycomb aluminum panels, our company has a professional technical R&D team that can help you choose the right aluminum honeycomb panel for your project, provide installation guidance, and answer any questions you may have. WORTHWILL Co., Ltd. has decades of industry experience and is your trusted partner for aluminum honeycomb panel solutions.

Please feel free to contact us: Contact us

- Provide free samples for your reference

- Reply to your message within 12 hours

- Professionals answer your questions

- Enthusiastic business team