Aluminum Jacketing

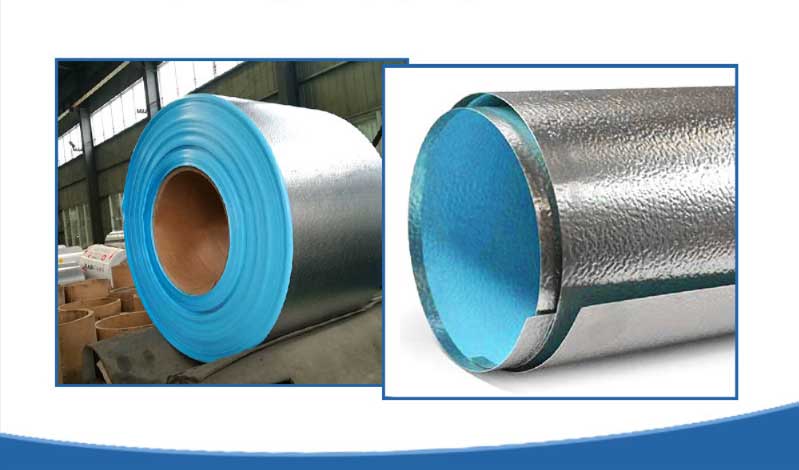

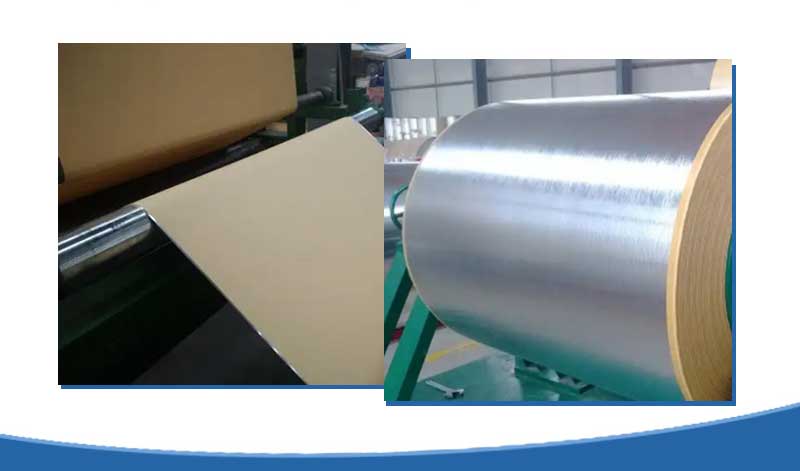

Worthwill's aluminum jacketing uses 1060, 1100, 3003, 3105 and other aluminum, and the surface treatment covers mill finished, embossed, Polysurlyn Moisture Barrier (PSMB), etc.

- Alloy:

- 1050, 1060, 1100, 3003, 3105, 5005, 5052, etc.

- Temper:

- H14, H24, H16, H26

- Thickness:

- 016" (0.4mm), 020" (0.5mm), 024" (0.6mm), 032" (0.8mm), or customized, from 0.15mm to 2mm

- Width:

- 36", 48", 914mm, 1000mm, 1200mm, 1219mm, and other available widths.

- Length:

- 50' (15 meters), 100' (30 meters), 200' (60 meters), 300' (90 meters), or customized according to your requirements.

- Standards:

- ASTM B209, ASTM C1729, EN573-1.

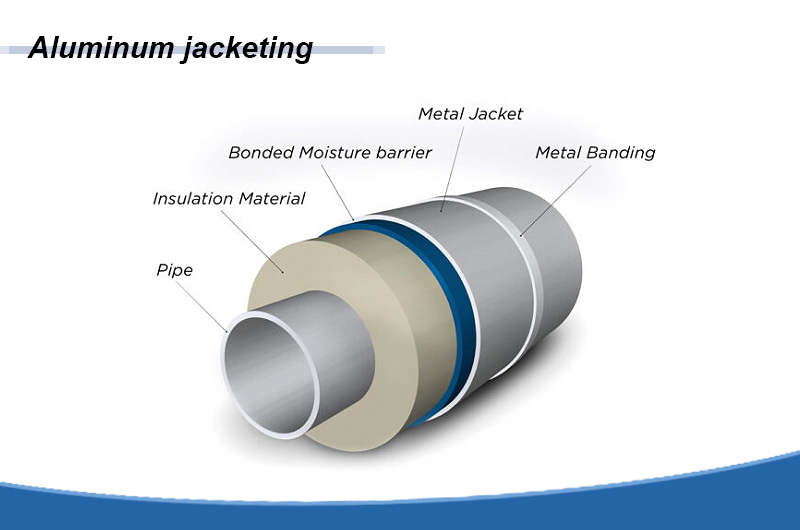

What is the Aluminum Jacketing

Aluminum jacketing is a kind of metal aluminum jacket, usually used with expanded polystyrene (EPS), PVC, polyurethane foam, rock wool, glass wool, and other insulation materials for pipes, buildings, equipment, etc. It is also called aluminum roll jacketing.

Compared with iron jacketing, horseshoe, galvanized iron, aluminum jacketing is becoming the most popular metal jacketing due to its light weight, corrosion resistance, anti-static, easy installation and recyclability.

Aluminum Jacketing Alloy Comparison

Common alloys for Aluminum jacketing include 1050, 1060, 1100, 1200, 3003, 3105, 5005, 5052.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al | Physical Properties |

|---|---|---|---|---|---|---|---|---|---|---|

| 1100 | - | - | - | - | - | - | - | - | Balance | Tensile Strength: 110-130 MPa, Yield Strength: 70-90 MPa, Elongation: ≥20% |

| 1050 | 0.20-1.00 | 0.70-1.00 | - | 0.04 | - | - | - | - | Balance | Tensile Strength: 110-130 MPa, Yield Strength: 70-90 MPa, Elongation: ≥20% |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | - | Tensile Strength: 110-130 MPa, Yield Strength: 70-90 MPa, Elongation: ≥20% |

| 1200 | 0.03 | 0.50 | 0.10 | 0.05 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | Tensile Strength: 130-150 MPa, Yield Strength: 90-110 MPa, Elongation: ≥15% |

| 3003 | 0.30 | 0.70 | 0.05-0.20 | 0.10 | 1.2-1.8 | - | 0.10 | - | - | Tensile Strength: 120-140 MPa, Yield Strength: 80-100 MPa, Elongation: ≥12% |

| 3104 | 0.50 | 0.70 | 0.10 | 0.10 | 0.8-1.3 | - | 0.10 | - | - | Tensile Strength: 130-150 MPa, Yield Strength: 90-110 MPa, Elongation: ≥10% |

| 3105 | 0.50 | 0.70 | 0.10 | 0.10 | 0.40-1.0 | - | 0.10 | - | - | Tensile Strength: 140-160 MPa, Yield Strength: 100-120 MPa, Elongation: ≥8% |

| 5052 | 0.20-0.60 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.10 | 0.10 | 0.10 | - | Tensile Strength: 220-240 MPa, Yield Strength: 140-160 MPa, Elongation: ≥16% |

Aluminum Jacketing Size Chart

| Pipe Size (Nominal Pipe Diameter) | Insulation Thickness (Inches) | Aluminum Jacketing Size |

|---|---|---|

| 1/2" | 1/2" | #1 |

| 3/4" | 1/2" | #2 |

| 1" | 1/2" | #3 |

| 1 1/4" | 1/2" | #4 |

| 1 1/2" | 1/2" | #5 |

| 2" | 1/2" | #6 |

| 2 1/2" | 1/2" | #7 |

| 3" | 1/2" | #8 |

| 3 1/2" | 1/2" | #9 |

| 4" | 1/2" | #10 |

| 5" | 1/2" | #11 |

| 6" | 1/2" | #12 |

| 8" | 1/2" | #13 |

| 10" | 1/2" | #14 |

| 12" | 1/2" | #15 |

| 14" | 1/2" | #16 |

| 16" | 1/2" | #17 |

| 18" | 1/2" | #18 |

| 20" | 1/2" | #19 |

| 24" | 1/2" | #20 |

| 1/2" | 3/4" | #21 |

| 3/4" | 3/4" | #22 |

| 1" | 3/4" | #23 |

| 1 1/4" | 3/4" | #24 |

| 1 1/2" | 3/4" | #25 |

| 2" | 3/4" | #26 |

| 2 1/2" | 3/4" | #27 |

| 3" | 3/4" | #28 |

| 3 1/2" | 3/4" | #29 |

| 4" | 3/4" | #30 |

| 5" | 3/4" | #31 |

| 6" | 3/4" | #32 |

| 8" | 3/4" | #33 |

| 10" | 3/4" | #34 |

| 12" | 3/4" | #35 |

| 14" | 3/4" | #36 |

| 16" | 3/4" | #37 |

| 18" | 3/4" | #38 |

| 20" | 3/4" | #39 |

| 24" | 3/4" | #40 |

| 1/2" | 1" | #41 |

| 3/4" | 1" | #42 |

| 1" | 1" | #43 |

| 1 1/4" | 1" | #44 |

| 1 1/2" | 1" | #45 |

| 2" | 1" | #46 |

| 2 1/2" | 1" | #47 |

| 3" | 1" | #48 |

| 3 1/2" | 1" | #49 |

| 4" | 1" | #50 |

| 5" | 1" | #51 |

| 6" | 1" | #52 |

| 8" | 1" | #53 |

| 10" | 1" | #54 |

| 12" | 1" | #55 |

| 14" | 1" | #56 |

| 16" | 1" | #57 |

| 18" | 1" | #58 |

| 20" | 1" | #59 |

| 24" | 1" | #60 |

| 1/2" | 1 1/2" | #61 |

| 3/4" | 1 1/2" | #62 |

| 1" | 1 1/2" | #63 |

| 1 1/4" | 1 1/2" | #64 |

| 1 1/2" | 1 1/2" | #65 |

| 2" | 1 1/2" | #66 |

| 2 1/2" | 1 1/2" | #67 |

| 3" | 1 1/2" | #68 |

| 3 1/2" | 1 1/2" | #69 |

| 4" | 1 1/2" | #70 |

| 5" | 1 1/2" | #71 |

| 6" | 1 1/2" | #72 |

| 8" | 1 1/2" | #73 |

| 10" | 1 1/2" | #74 |

| 12" | 1 1/2" | #75 |

| 14" | 1 1/2" | #76 |

| 16" | 1 1/2" | #77 |

| 18" | 1 1/2" | #78 |

| 20" | 1 1/2" | #79 |

| 24" | 1 1/2" | #80 |

| 1/2" | 2" | #81 |

| 3/4" | 2" | #82 |

| 1" | 2" | #83 |

| 1 1/4" | 2" | #84 |

| 1 1/2" | 2" | #85 |

| 2" | 2" | #86 |

| 2 1/2" | 2" | #87 |

| 3" | 2" | #88 |

| 3 1/2" | 2" | #89 |

| 4" | 2" | #90 |

| 5" | 2" | #91 |

| 6" | 2" | #92 |

| 8" | 2" | #93 |

| 10" | 2" | #94 |

| 12" | 2" | #95 |

| 14" | 2" | #96 |

| 16" | 2" | #97 |

| 18" | 2" | #98 |

| 20" | 2" | #99 |

| 24" | 2" | #100 |

Types of Aluminum Jacketing

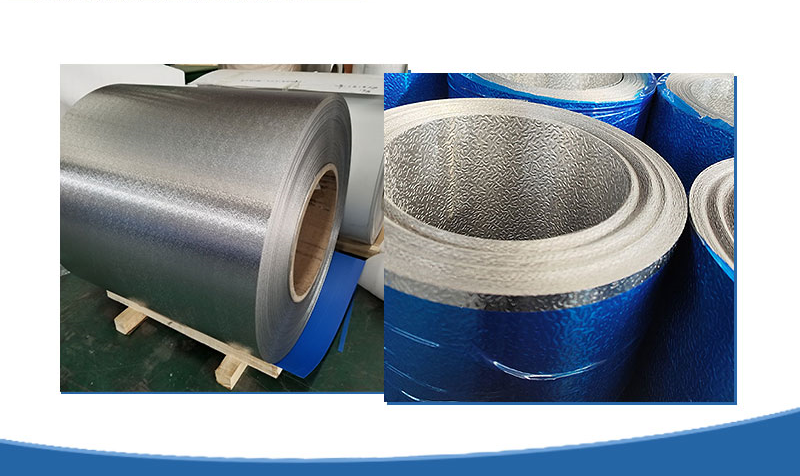

According to the different surface treatment processes of aluminum jackets, aluminum insulation jacketing can be divided into mill finished jacketing, stucco embossed jacketing, aluminum jacketing with polysurlyn moisture barrier, etc.

A layer of orange peel texture is rolled on the surface of the mill finished jacketing by a stucco embossed roller, which is beneficial to heat dissipation and also improves strength.

Stucco embossed jacketing

- Common alloys: 1060, 1100, 3003.

- Thickness range: 0.3mm-1.5mm.

Mill finish aluminum jacketing is a raw processing state with smooth surface and good economy. It is often used for equipment and pipeline insulation.

Mill finish aluminum jacketing

- Common alloys: 1050, 1060, 1100, 3003, 3105, 5005, 5052.

- Thickness range: 0.3mm-2mm.

A layer of polysurlyn moisture barrier is applied to the surface of mill finished sheet or coil to improve moisture and corrosion resistance.

Aluminum jacketing with polysurlyn moisture barrier

- Common alloys: 1060, 1100, 3003, 3105, 5052.

- Thickness range: 0.3mm-1.5mm.

Aluminum jacketing with Polykraft Moisture Barrier (PKMB) is aluminum sheets or coils that are laminated with a protective layer made of kraft paper bonded with polyethylene.

Aluminum jacketing with polykraft moisture barrier

- Common alloys: 1060, 1100, 3003, 3105, 5052.

- Thickness range: 0.3mm-1.5mm.

The surface is coated with PE, PVDF or epoxy varnish paint, with various colors. Among them, PE coated jacketing is suitable for indoor insulation, and PVDF coated jacketing is suitable for outdoor insulation.

Color coated aluminum jacketing

- Common alloys: 1050, 1060, 1100, 3003, 3105.

- Thickness range: 0.3mm-2mm.

The corrugated design on the surface of the aluminum jacket increases the strength and rigidity of the material, making it more resistant to external impact and extrusion.

Corrugated aluminum jacketing

- Common alloys: 1060, 3003.

- Thickness range: 0.3mm-1.5mm.

Application of Aluminum Jacketing

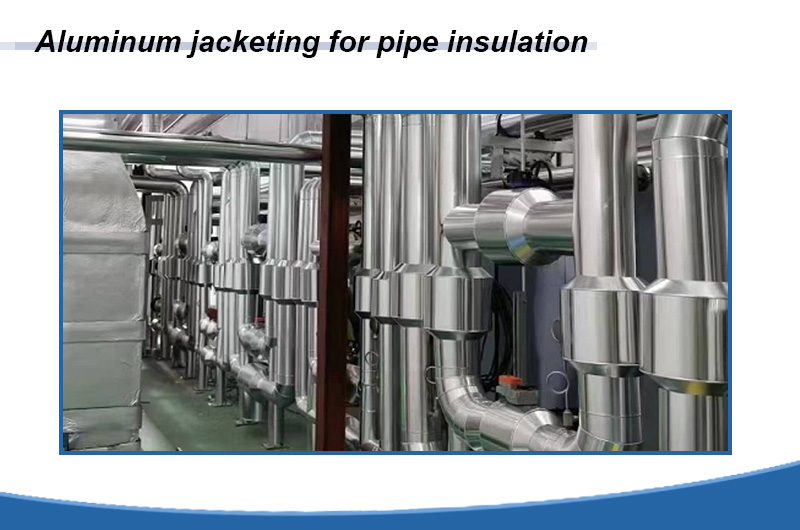

Aluminum jackets are commonly used for insulation of piping systems, and can also be used for insulation of storage tanks, heat exchangers, acid storage tanks, building curtain walls and equipment, etc.

Aluminum jacketing for pipe insulation

Aluminum jacketing for pipe insulation is the most commonly used field among all aluminum jacketing applications. It requires aluminum jacketing to have low thermal conductivity, low density, good flexibility and other characteristics.

Aluminum jacketing for equipment insulation

The metal materials used for equipment insulation have relatively low requirements for aluminum jackets, usually 1060 jacketing roll and 3003 jacketing roll.

Aluminum jacketing for building insulation

Metal building insulation rolls have various colors, beautiful appearance, and strong decorative power. They are usually 1000 series pure aluminum and 3000 series aluminum-manganese alloys.

Aluminum Jacketing VS Iron Jacketing

In the field of metal insulation materials, aluminum and iron (usually galvanized steel) as protective and decorative layers, each has its own characteristics and application scenarios.

| Feature | Aluminum jacket | Galvanized Steel jacket |

|---|---|---|

| Density | Low (lightweight) | High (heavier) |

| Corrosion Resistance | High, not prone to rust | Moderate, galvanized layer provides protection but susceptible to corrosion |

| Thermal Conductivity | Moderate | High |

| Plasticity | High, easy to shape | Moderate |

| Processability | ||

| Cutting | Easy | Easy |

| Bending | Easy | Difficult (especially with thick plates) |

| Welding | Difficult (requires special techniques) | Easy |

| Installation and Maintenance | ||

| Ease of Installation | High, lightweight and easy to handle | Moderate, heavier and requires more labor |

| Maintenance Requirements | Low, not prone to rusting | Moderate, need to regularly check the galvanized layer |

| Recyclability | High, easy to recycle | Moderate, recyclable but more complex to process |

| Cost | ||

| Material Cost | Moderate | Lower |

| Installation Cost | Lower, due to light weight | Higher, due to weight |

| Aesthetics | ||

| Surface Treatment | Diverse, can be anodized, coated, etc. | Diverse, can be coated, galvanized, etc. |

| Color Options | Diverse | Diverse |

| Environmental Adaptability | ||

| Weather Resistance | High, suitable for outdoor use | Moderate, suitable for outdoor use but requires rust prevention |

| Temperature Resistance | Good, suitable for a wide temperature range | Good, suitable for a wide temperature range |

| Thermal Insulation Performance | Poor, aluminum is a good conductor of heat | Better, iron has greater thermal resistance |

| Fire Resistance | Low, aluminum has a low melting point | High, iron has a high melting point |

Installation Guide

In the field of metal insulation materials, aluminum and iron (usually galvanized steel) as protective and decorative layers, each has its own characteristics and application scenarios.

Preparation Work

- Inspect the materials to ensure the aluminum jacketing dimensions, and surface treatment meet the design specifications.

- Prepare the necessary tools, such as scissors, measuring tapes, marking pens, rivet guns, sealants, etc.

- Check the installation environment to ensure there is no strong wind, rain, or other adverse weather conditions, and that the temperature is suitable.

Measurement and Cutting

- Measure the dimensions accurately based on the size and shape of the insulation material.

- Mark and cut the aluminum jacketing using a marking pen and scissors or specialized cutting tools.

Cleaning and Surface Treatment

- Clean the insulation material to ensure it is dust-free and free of oil stains.

- Edge treatment of the aluminum jacketing, if necessary, to facilitate installation and sealing.

Installation and Fixing

- Fix the aluminum jacketing using rivets or other fasteners onto the insulation material, ensuring the fasteners are evenly spaced and securely fixed.

- Seal the seams of the aluminum jacketing with sealant or tape to prevent water and air infiltration.

Checking for Flatness

Adjust for flatness, checking the flatness of the aluminum jacketing and making adjustments if necessary to ensure a neat appearance.

Final Inspection

- Double-check that all fastenings are secure and the seals are in place.

- Clean up any dust generated during the installation process.

Why Choose Us

Worthwill is a professional manufacturer of aluminum jacketing, and our products fully comply with standards such as ASTM B209, ASTM C1729, EN573-1.

We default to using sea transportation packaging that fully complies with international practices, taking into account the various environments faced by aluminum jacketing during long-term transportation, ensuring that the aluminum jacketing products delivered to our customers are perfect.

- Annual Capacity

- 300, 000+

- Customer volume

- 90, 000+

- Exported to Countries

- 86

Frequently Asked Questions

Is aluminum good for insulation?

Metal jacketing materials are usually made of iron jacketing (galvanized steel) and aluminum jacketing. Aluminum has characteristics such as rust prevention, corrosion resistance, and recyclability, making it the best jacketing material.

What is the difference between aluminum jacketing and insulation materials?

The jacketing is the outermost metal jacketing of the pipeline system, commonly made of materials such as tinplate, stainless steel, and galvanized steel plates (iron jacketing), used to protect the insulation layer and pipelines from water, moisture, ultraviolet radiation, and chemical damage. The insulation layer is located between the jacketing and the pipeline and is the most important part of the pipeline insulation, usually including PVC, polyurethane foam, rock wool, glass wool, glass fiber, etc., and their functions and materials are completely different.

Something you might be interested in

You may be interested in some other information about aluminum roll jacketing