Aluminum Sublimation Sheet

Aluminum sublimation sheet is one kind of sublimation metal sheet, also know as 'printable aluminum sheet', Worthwill's sublimation aluminum sheet has a variety of colors and excellent adhesion, Free A4 samples available.

- Alloy:

- 1050, 1060, 1070, 1100, 3003 etc.

- Thickness:

- 0.02", 0.22mm, 0.35mm, 0.45mm, 0.55mm, 0.65mm, 1mm, up to 2mm.

- Dimensions:

- 200x300mm, 300x600mm, 12"x24", 24"x36", etc.

- Corner options:

- Square, Rounded.

- Color:

- gold, silver, pear silver, etc., or according to your needs.

- Surface treatment:

- Brushed, Mirror, Matte, High glossy, Satin, wood grains etc.

What is the sublimation aluminum sheet?

Aluminum sublimation sheet is made of aluminum alloy, it is one kind of sublimation metal sheet, and aluminum sublimation sheet also know as "Printable aluminum sheet".

Its surface is treated with a special coating, which is usually a PE paint that supports dye sublimation transfer, which can permanently transfer images or designs to its surface through dye sublimation printing technology.

Composition- Aluminum sheet base: as a supporting material.

- Alkane silicon connecting layer: enhances the adhesion of the coating to the aluminum sheet base.

- Background coating: usually a pure white polyester base coating, with titanium dioxide as the main raw material, providing a uniform background color.

- Dye sublimation medium coating: a transparent polyester top coating without titanium dioxide, ensuring that the ink can penetrate and fix smoothly while maintaining the vividness of the color.

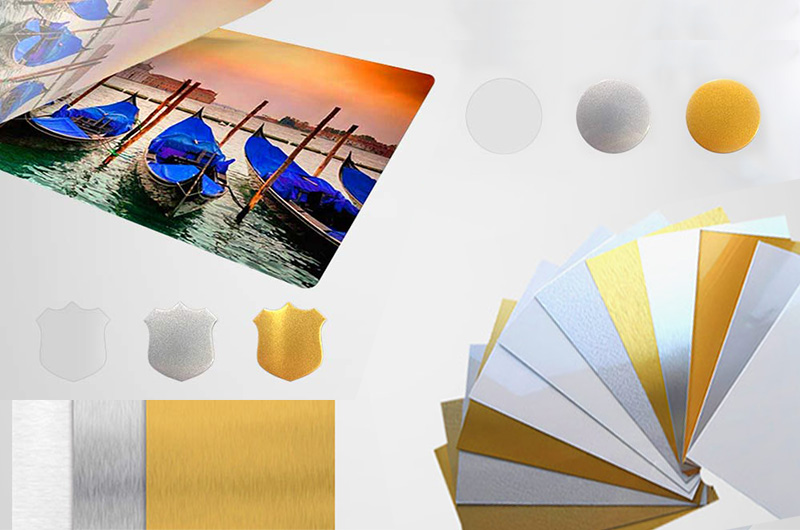

Type of sublimation aluminum sheet

Worthwill can customize different types of sublimation aluminum sheets / blanks according to your needs, whether it is brushed, mirrored, high glossy, matte sublimation sheet or sublimation sheet with holes.

High glossy white sublimation sheet

Matte white sublimation sheet

Satin gold sublimation sheet

Satin silver sublimation sheet

Pearlized gold sublimation sheet

Pearlized silver sublimation sheet

Pearlized white sublimation sheet

Brushed gold sublimation sheet

Brushed silver sublimation sheet

Brushed coppery sublimation sheet

Titanium silver sublimation sheet

Titanium gold sublimation sheet

Mirror gold sublimation sheet

Mirror light gold sublimation sheet

Mirror silver sublimation sheet

Matte champagne sublimation sheet

In addition, we can also produce wood grain sublimation sheets such as walnut, beech, oak, elm, yellow pear, ebony, and rosewood, and the color can also be customized according to requirements.

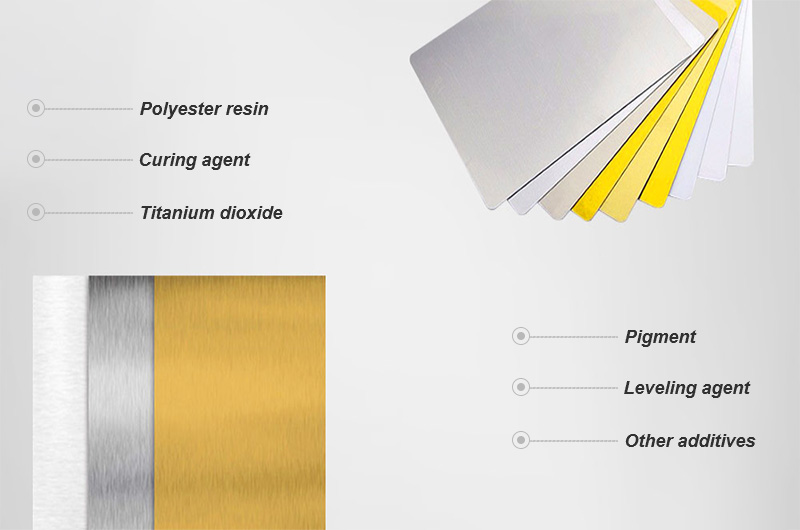

Coating composition materials

- Polyester resin: as a film former, providing the basic structure and mechanical properties of the coating.

- Curing agent: such as TGIC (melamine formaldehyde resin) or HAA (hydroxyalkylamide), mixed with polyester resin to produce cross-linked polymers to form a hard coating film.

- Titanium dioxide: used in the background coating to provide a white background.

- Pigment: gives the coating the required color, plays a filling and covering role.

- Leveling agent: improves the leveling of the coating and makes the coating surface smoother.

- Other additives: such as matting agents, wax powder, etc., used to adjust the gloss and other properties of the coating.

Price of aluminum metal sublimation sheet

Price = SMM ingot A00 price + processing cost

Sublimation aluminum sheet prices vary by surface finish. Brushed sublimation sheets are 10% more expensive than standard ones, while mirror-finish sublimation sheets can cost up to 40% more.

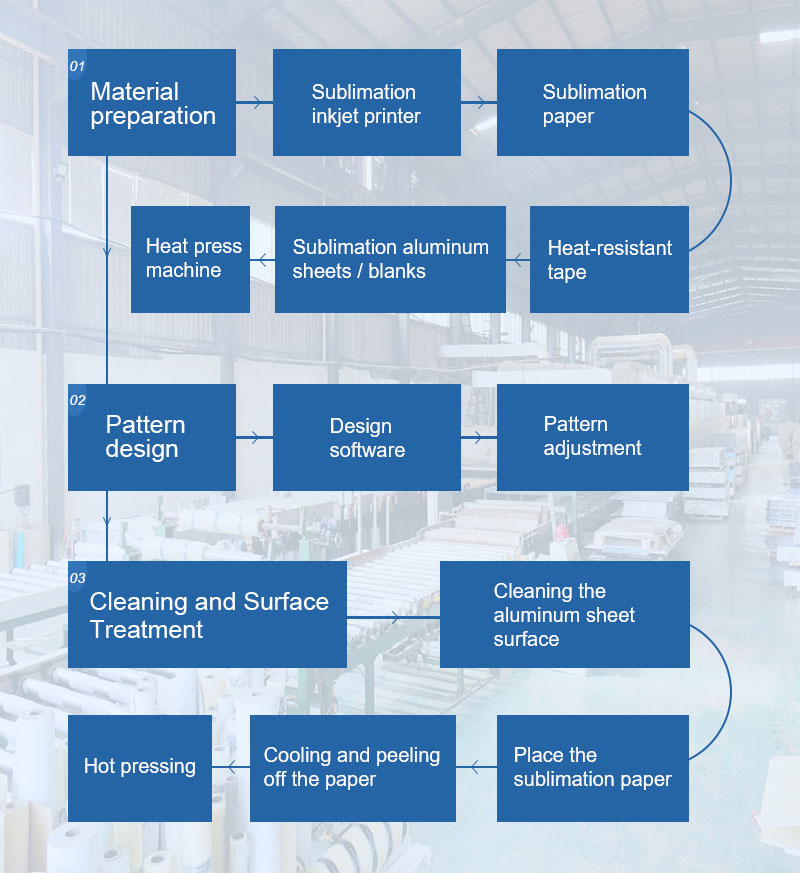

How to sublimate an image to aluminum?

Step 1: Material preparation

- Sublimation inkjet printer: Choose a printer suitable for sublimation transfer, and ensure that it can handle high-resolution printing needs.

- Sublimation paper: Choose high-quality dye sublimation paper to ensure that the pattern can be clearly transferred to the sublimation sheet.

- Sublimation aluminum sheets / blanks: Choose the appropriate size and thickness according to the project requirements.

- Heat-resistant tape: to fix the sublimation paper

- Heat press machine: Used to apply high temperature and pressure to transfer the pattern from the sublimation paper to the sublimation sheet.

Step 2: Pattern design

- Design software: Use design software such as Adobe Photoshop or CorelDRAW to ensure that the resolution of the design pattern is not less than 300 DPI.

- Pattern adjustment: Adjust the pattern size according to the size of the metal sublimation sheet or blank, and ensure the symmetry and integrity of the pattern.

Step 3: Cleaning and Surface Treatment

- Cleaning the aluminum sheet surface: Use alcohol or special cleaner to clean the sublimation aluminum sheet surface to ensure that it is clean and dust-free.

- Place the sublimation paper: Place the printed sublimation paper pattern down on the sublimation aluminum sheet surface.

- Hot pressing: Put the sublimation aluminum sheet and sublimation paper into the hot press together, set the temperature to 180-204℃, and the pressure time to 30-90 seconds.

- Cooling and peeling off the paper: After the hot pressing is completed, let the sublimation aluminum sheet cool naturally, and then carefully peel off the sublimation paper.

Metal materials sublimation times and temperatures chart

The heat press machine temperature of metal sublimation materials is 350-400°F (177-204°C), the heat pressing time is mostly 60s, and flat pressure and medium pressure are mainly used.

| Material | Temperature (°C) | Time (s) | Pressure (psi) |

|---|---|---|---|

| Sublimation Aluminum for Photo | 350-400°F (177-204°C) | 30-90 | Flat Press - Face up, medium pressure(35-40 psi) |

| Sublimation Aluminum Blanks for Keychain | 350-400°F (177-204°C) | 30-90 | Flat Press - Face up, medium pressure(40 psi) |

| Stainless Steel | 380°F (193°C) | 60-80 | Flat Press - Face up, medium pressure(35-40 psi) |

| Galvanized Metal | 350-400°F (177-204°C) | 60-90 | Flat Press - Face up, medium pressure(35-40 psi) |

| Metal (General) | 375-400°F (190-204°C) | 60-90 | Flat Press - Face up, medium pressure(35-40 psi) |

| Polyester | 400° F (204°C) | 40-60 | Flat Press - Face up, medium pressure(40 psi) |

| Ceramic | 350-400°F (177-204°C) | 150-210 | Flat Press - Face up, medium to high pressure (35 to 50 psi) |

Essential Sublimation Printing Tips: Different materials require specific settings, test prints help determine the best configuration. Use 30-40 psi for medium pressure and 20-30 psi for light pressure, tailored to your material and heat press machine.

Advantages and Benefits

High-definition patterns with vivid colors and a unique surface texture.

High wear and corrosion resistance, ensuring long-term durability. Easy to clean with water, reducing maintenance costs.

Wood-like texture, odorless, and pollution-free, making it an environmentally friendly material.

Size, shape, pattern and color can be customized according to customer needs.

Good fireproof performance for safe use.

Longer service life (7-20 years) with no discoloration or deformation.

Application

As dye sublimation aluminum sheets gain popularity, their usage is expanding. 0.5mm sheets suit lightweight decorative needs, while 1mm sheets are ideal for general decoration and light structural applications.

Advertising

- Billboard

- Table

- Business cards, nameplates.

- Exhibition Board

Identification field

- Car Logo

- Process identification

- Trademark

- Logo Signage

Home Furnishing

- Decorative paintings

- Photo panel

Electronics

- Mobile phone case

- Personalized computer case

Packaging and shipping

We use standard export packaging: aluminum sublimation sheets are covered with protective film, wrapped in kraft paper and transparent protective paper. If weight exceeds 100kg, a wooden pallet is used for transport and handling. For special needs, contact sales staff in advance and we'll try our best to accommodate.

- FedEx/DHL/UPS/TNT, door to door.

- Large quantities of goods are transported by air or sea in full containers and received at airports and ports.

- Send to the customer's designated freight forwarder.

- Customer negotiates shipping method.

- Samples can be shipped within 3-7 days, bulk shipments within 5-20 days.

Why Choose Us

Worthwill is a professional sublimation aluminum sheets and blanks supplier and manufacturer, which has been exported to 76 countries and regions in the world. Its customers include private enterprises, distributors, wholesalers, and individuals.

In addition, we have a large number of sublimation aluminum sheets blanks in stock in sizes of 8"x10", 12"x24", 24"x36", 12cmx24cm.

Service:- Brushed: Brushed gold, Brushed silver, Brushed coppery.

- Polishing: Mirror gold, Mirror light gold, Mirror silver.

- Punching: Support round holes, square holes, rounded corners.

- Customizable: Color, size, thickness, surface treatment.

- Cut to size: Especially good at A4 size, A3 size, 12"x24", 24"x36".

- Free A4 samples available.

Frequently Asked Questions

What temperature do you sublimate aluminum?

The optimal sublimation temperature for aluminum sheets is typically around 400°F (204°C) for sharp and vibrant prints.

However, it can vary depending on the sheet type and coating: some may require 385°F (196°C) or 350°F (177°C), while thicker sheets might need 335°F (168°C) for longer durations.

what kind of metal can you sublimate on?

Dye sublimation printing can be done on several metals with a special coating:

- Aluminum: Used for photo prints, signs, awards.

- Stainless Steel: Ideal for custom gifts and industrial use.

- Brass: Used for high-quality gifts.

- Galvanized Metal: Suitable for outdoor signs.

Key points: Metals must have a polyester or polyacrylic coating to accept sublimation inks.

What are the settings for aluminum sheets for sublimation?

For sublimation on aluminum sheets, the typical settings are:

- Temperature: 385°F - 400°F (196°C - 204°C).

- Time: 45 - 60 seconds (or up to 90 seconds for thicker sheets).

- Pressure: Medium pressure, around 40 psi.

Key points: Ensure aluminum sheets have a polyester coating to accept the inks. Always test with a small piece first.

Are you a sublimation aluminum sheets manufacturer or a wholesaler?

We are 100% factory for sublimation aluminum, you can visit the factory at any time, or check the factory online through VR.