Mirror Finish Aluminum

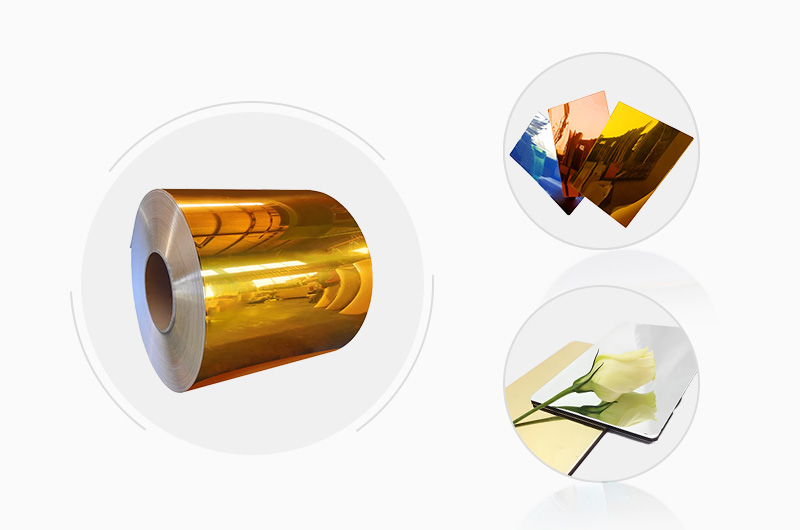

Worthwill offers mirror aluminum sheets / coils with over 86% reflectivity, available in alloys 1050, 1070, 1085, 3003, 3105, 5454, 5754, etc. Custom solutions include mirror anodized aluminum, mirror coated aluminum, and ACP mirror sheets. Multiple color options: gold, black, champagne, bronze, and more.

- Alloy:

- 1050, 1070, 1085, 3003, 3105, 5454, 5754, etc.

- Product type:

- Coil, sheet.

- Thickness:

- 0.1mm - 10mm.

- Width:

- 10mm-2600mm.

- Reflectivity:

- 80%, 86%, 95%.

- Coating Type:

- PE, PVDF.

- Surface Treatment:

- Mirror embossed, mirror anodized, mirror coated, ACP mirror sheets, etc.

What is the Mirror Finish Aluminum?

Mirror finish aluminum refers to aluminum sheets or coils with a mirror-like surface finish achieved through processes such as rolling and polishing.

Polishing is the key process for conventional mirror aluminum (≥86% reflectivity), which explains their technical name: mirror polished aluminum sheets and coils.

Features and Benefits:- High Reflectivity: Standard reflectivity of 86%+, High reflective mirror aluminum can reach 95%+.

- Surface Quality: Scratch-free, easy to clean, burr-free edges.

- Processing Flexibility: Supports single/double-sided coating and customized leveling.

Worthwill offers a variety of mirror aluminum products, including mirror finish sheets, coils, and ACP mirror sheets.

Mirror Aluminum Alloy and Specifications

| Alloy Series | Typical Models | Temper | Width(mm) | Thickness (mm) | Reflectivity | |

|---|---|---|---|---|---|---|

| 1000 Series | 1050/1070/1085 | O, H12, H14, H16, H18, H24 | 10-1700 | 0.1-3.5 | 80% 86% 95% | |

| 3000 Series | 3003/3105 | O, H12, H14, H18, H19 | 10-1700 | 0.15-10 | 85% 86% 95% | |

| 5000 Series | 5454/5754 | O, H22, H32, H111, H112 | 1200-2600 | 2-8 | 80% 86% 95% |

Surface Treatment Categories

Worthwill can provide additional services such as embossing, anodizing, color coating, film lamination, drilling, hemming, etc. based on the mirror finish aluminum sheet.

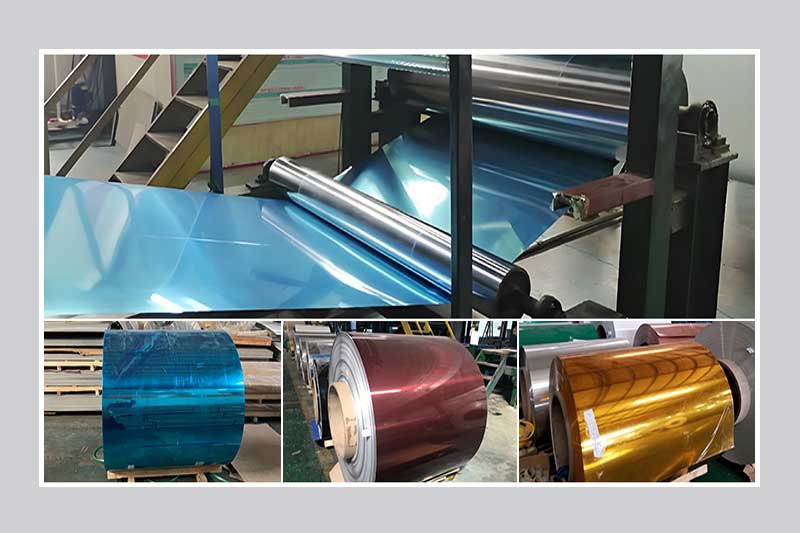

Mirror Coated Aluminum

Coated mirror-like aluminum sheet is a pre-finished material with a reflective surface and colored PE / PVDF coating, combining decorative appeal and durability.

- Thickness(mm): 0.2-0.5.

- Width(mm): 1000-1500.

- Reflectivity: 85%-87%.

- Coating Types: PVDF coating (outdoor, 15 years) / PE coating(indoor).

- Color Options: Gold, black, copper, rose gold, bronze, more colors.

- Coating Thickness Standards: PVDF coating >25μm, PE coating >16μm.

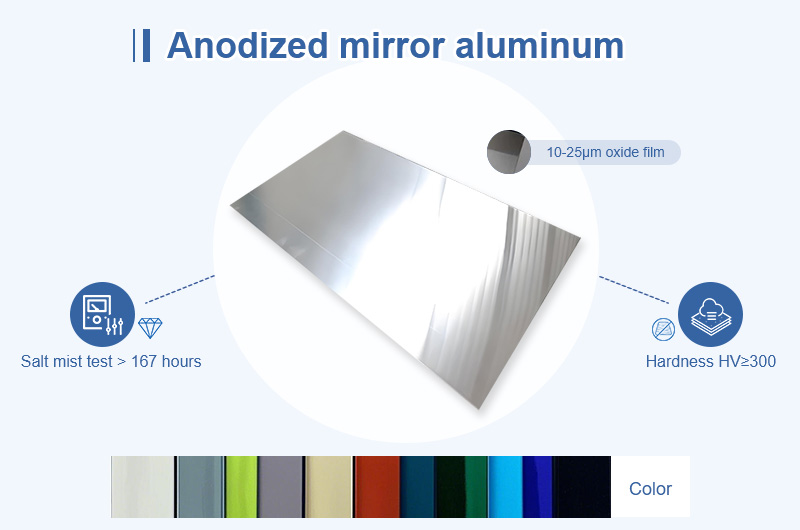

Mirror Anodized Aluminum

Mirror anodized aluminum sheet/coil undergoes anodization to form a durable, dense insulating oxide layer on its surface, with customizable color options.

- Thickness tolerance (mm): a:(0.2-0.5) ±0.03, b: (0.6–0.8) ±0.04.

- Diffuse reflectance: Less than 12%.

- Reflectivity: More than 86%.

- Process Features: Forms a 5-25μm oxide layer, hard anodizing can reach 25-125μm.

- Performance Indicators: Salt spray test >167 hours, hardness HV≥300.

- Color Options: 7 standard colors + custom colors, more colors.

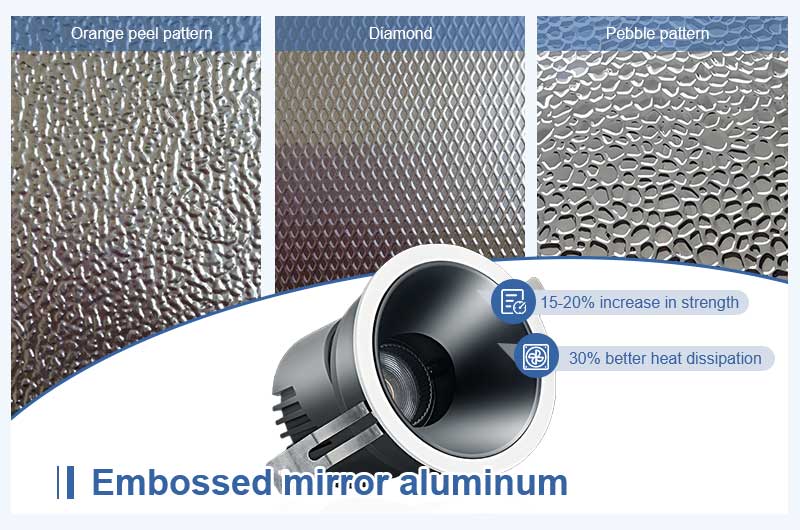

Mirror Embossed Aluminum

Embossed aluminum mirror sheets/coils feature concave and convex patterns that enhance surface area for improved heat dissipation while increasing material strength.

- Thickness(mm): 0.1 - 3.

- Width(mm): 800-1220.

- Reflectivity: More than 86%.

- Pattern Types: Orange peel, diamond, pebble, etc.

- Enhanced Functions: 30% better heat dissipation, 15-20% stronger.

- Applications: Industrial radiators, lamp, decorative building materials.

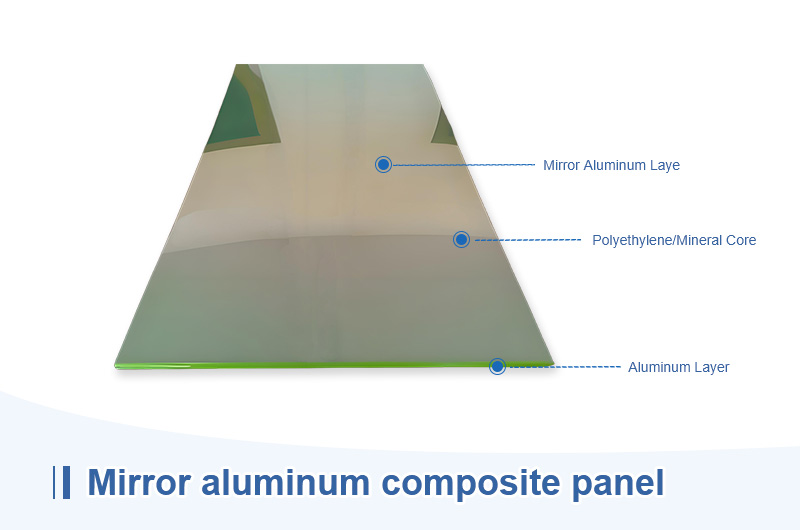

Mirror Aluminum Composite Panel

ACP mirror sheets (also called ACM) are composite panels with two aluminum layers bonded to a polyethylene or mineral core.

- Size(mm): 1220 x 2440(4' x 8'), 1500 x 3050(5' x 10').

- Thickness: 2mm - 6mm, recommend 3mm and 4mm.

- Alu Skin Thickness: 0.10mm - 0.50mm, recommend 0.21mm, 0.30mm.

- Coating: PE, PVDF, 1 sides or 2 sides.

- Linear Thermal Expansion: 2.0mm/m.

- Thermal Resistance (m2k/m): 0.0069.

Customizable Color Chart

Mirror finished aluminum sheets and coil from Worthwill offer a wide range of anodizing color and coatings color such as black, bronze , gold, etc, and color is customizable.

Anodizing Color Chart

Clear

Desert Tan

Olive Brown

Gray

Orange

Gold

Green

Red

Blue

Violet

Pink

Black

Color Coatings Color Chart

Gold mirror aluminum

Black mirror aluminum

Titanium gold mirror

Copper mirror aluminum

Rose mirror aluminum

Bronze mirror aluminum

Processing Workflow: How to Polish Aluminum to Mirror Finish?

Step 1: Material preparation

- Alloy selection.

- Sheet cutting.

Step 2: Surface Pre-Treatment

- Cleaning.

- degreasing.

- acid washing.

Step 3: Polishing

- Mechanical Polishing: Rough grinding -> Fine grinding -> Polishing.

- Chemical Polishing: Soaking -> Rinsing.

- Electrolytic Polishing: Anode treatment -> Electrolyte treatment -> Rinsing.

Step 4: Surface Treatment (Optional): Anodizing, coating, embossing.

Step 5: Cutting and Forming(Optional): Cutting, bending, stamping.

Step 6: Quality Inspection

- Reflectivity test: ≥86%.

- Salt spray test: Evaluates corrosion resistance of oxide layer or coating.

- Scratch test: Mohs hardness ≥3.

- Fingerprint test: Oleophobic coating contact angle >110°.

- Bending test: 90° bending without cracks (hot-rolled sheets).

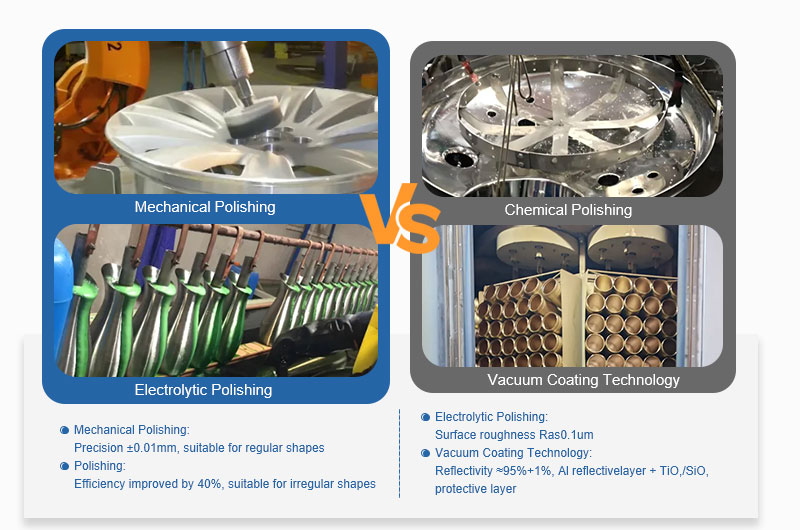

Polishing Process Comparison

- Mechanical Polishing: Precision ±0.01mm, suitable for regular shapes.

- Chemical Polishing: Efficiency improved by 40%, suitable for irregular shapes.

- Electrolytic Polishing: Surface roughness Ra≤0.1μm.

- Vacuum Coating Technology: Reflectivity ≈95%±1%, Al reflective layer + TiO₂/SiO₂ protective layer.

Selection Recommendations

For Outdoor Environments:

- Fluorocarbon-coated sheets (best weather resistance).

- 5000 series alloys (strong corrosion resistance).

For High Reflectivity Requirements:

- Vacuum-coated high-reflectivity aluminum (reflectivity 95%+).

- 1085 pure aluminum base material (highest base reflectivity).

For Complex Processing Requirements:

- Hot-rolled mirror sheets (elongation >25%).

- 3003 alloy (bending radius up to 1t).

Application

Architecture and Decoration(35% share)

- Curtain walls.

- Aluminum plastic composite plate (acp).

- Interior decoration.

New Energy (efficiency improved by 18%)

- Solar reflectors.

- solar heat collection materials.

Transportation (40% weight reduction vs. steel)

- Automotive decorative parts.

- Car wheels.

- Tank bodies.

Electronics (surface roughness <0.8μm)

- Lighting reflector.

- Lamp decoration.

- High-end product casings.

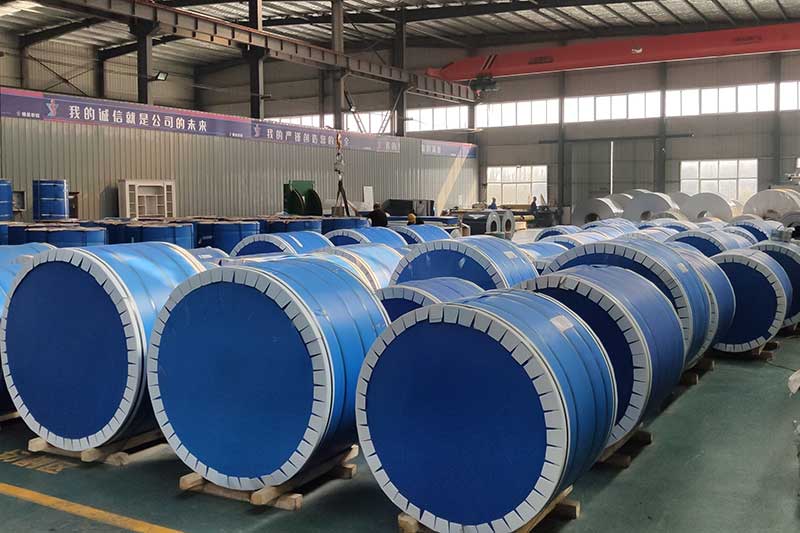

Packaging and Transportation

Once the mirror-finished aluminum surface sustains damage during transportation, the entire board becomes unusable.

To ensure product integrity, we implement a multi-layer protection system using specialized protective films combined with reinforced kraft paper wrapping.

Additionally, all handlers are strictly required to exercise extreme caution during transportation and storage processes.

Why Choose Us

Integrated manufacturer (80, 000㎡ plant, 200+ staff) ensuring end-to-end quality control for precision-engineered mirror aluminum sheet and ACP panels.

Key Advantages:- High reflectivity & corrosion resistance via specialized coatings

- Lightweight design cuts installation/logistics costs

- Versatile for architecture, electronics, automotive, and appliances

R&D-driven customization with scalable production and 24/7 technical support.

Client-Centric Value:Factory-direct model eliminates intermediaries, ensuring competitive pricing, rapid response, and 98% client retention.

Proven Expertise:Trusted in landmark projects (e.g., Hangzhou Tower Mall) with certified material reliability.

Something you might be interested in

You may be interested in some other information about Mirror Finish Aluminum