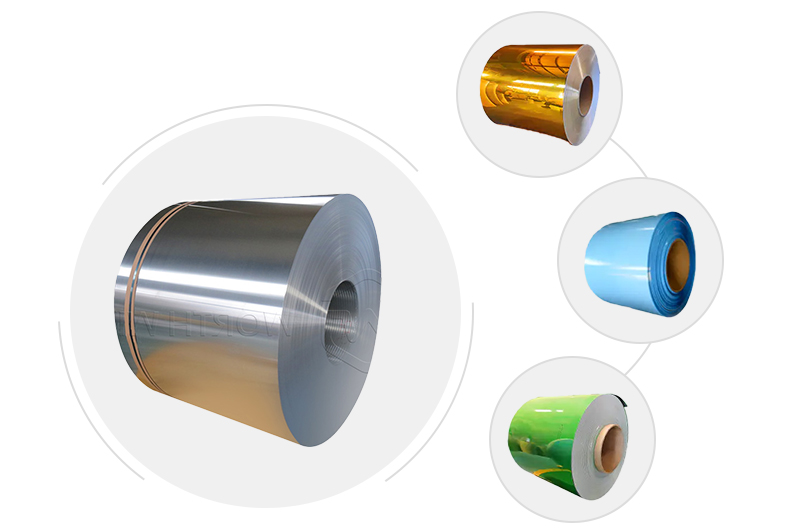

1000 series coated aluminum is divided into 1050, 1060, 1070, 1100, and 1200 according to their different aluminum contents. Among all series of aluminum coils, 1060 coated aluminum is an alloy with a purity of more than 99.6%. Due to excellent performance, 1060 coated aluminum materials are widely used in various industries.

1060 coated aluminum specification

| Product | 1060 coated aluminum |

| Temper | H42(H22)H44(H24) H46(H26) H48(H28) |

| Thickness | 0.18-3.0mm |

| Width | 100-1500mm |

| Length | Coil or customization |

| Coating | PE, PVDF, HDPE |

| Coating thickness | 16 - 18 microns, 25 microns upper |

| Color | RAL color, wooden grain, stone grain |

| Film | Protection film or customization |

| MOQ | 5 tons or stock |

| Production technique | Roller coating |

1060 plain aluminum performance

Chemical Properties and Mechanical Properties

Chemical Properties – EN AW-1060 Color Coated Aluminium Coil Strip

| Alloy Designation | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | V | Remarks | Others |

Aluminium min |

||

| Numerical | Chemical Symbols | Each | Total | |||||||||||||

|

EN AW -1060 |

EN AW- AI 99.6 |

0.24 | 0.35 | 0.05 | 0.03 | 0.03 | – | – | 0.05 | 0.03 | – | 0.05 | – | 0.03 | – | 99.60 |

Mechanical Properties – EN AW-1060 Color Coated Aluminium Coil Strip

| TOLERANCE | |||||

| Major Brand | A1060(O) | ||||

| Thickness | 0.2-0.4 | 0.4-0.8 | 0.9-1.1 | 1.2-1.6 | 1.8-2.0 |

| tolerance | ±0.01 | ±0.015 | ±0.02 | ±0.025 | ±0.03 |

| Width | <100 | 100-200 | 201-500 | 501-1250 | >1250 |

| tolerance | ±0.1 | ±0.2 | ±0.2 | ±1 | ±2 |

| BURR AND COLLAPSE | |||||

| The width of the aluminum belt | burr’s height | collapsed side’s height | |||

| <0.2 | 0.01 | ≥0.05-0.1 | |||

| 0.2-1.0 | 0.015 | ||||

| 1.1-1.5 | 0.02 | ||||

| >1.6 | 0.03 | ||||

| MECHANICAL PROPERTY | |||||

| U.T.S: 60-95N/mm2 | Elongation: >25% | ||||

| Density in 20°C :2.703kg/dm3 | Max. resistance in 20°C:≤0.02825Ωmm2/m | ||||

1060 aluminum material advantages

1060 aluminum alloy → lightweight properties → aerospace industry and automobile bodies

1060 aluminum alloy → excellent corrosion resistance → roofing materials, seawater, industrial chemicals

1060 aluminum alloy→ good electrical conductivity → heat transfer and electronic applications

1060 aluminum alloy → good formability and weldability → industrial tanks

1060 Coated/Painted aluminum application

Ceiling

1060 aluminum ceiling sheets are widely used in airports, stations, soho buildings, malls, and other home decorations. Coated aluminum 1060 is an ideal and modern interior decoration material.

Common specification:

| Plain aluminum (1060) | Perforated aluminum(1060) | |

| Alloy & temper | 1060 H16/H22/H24 | 1060 H16/H22/H24 |

| Thickness | 0.45 mm - 0.75 mm | 0.45 mm - 0.75 mm |

| Width | 600 - 700 mm | 600 - 700 mm |

| Length | Coil or Customized | Same with width |

| Coating | PE | PE |

| Coating thickness | 16-18 microns | 16-18 microns |

| Surface | PE 16-18 microns | With holes diameter 1.8 mm / 1.5 mm/2 mm |

| Market | Middle East, Southeast Asia market | Middle East, Southeast Asia market |

Signage

1060 painted aluminum is popular in the European signage market. 1060 aluminum has replaced 5754 and has become the first choice.

| Plain aluminum (1060) | Punched aluminum(1060) | |

| Alloy & temper | 1060H22/1060 H24 | 1060H22/1060 H24 |

| Thickness | 0.45-3 mm | 0.45-3 mm |

| Width | 20-1220 mm | 20-1220 mm |

| Coating | RAL7042A , RAL7043B, RAL9016,RAL9017, RAL5017. RAL3020,RAL2009, RAL1023,RAL6024 | RAL7042A , RAL7043B, RAL9016,RAL9017, RAL5017. RAL3020,RAL2009, RAL1023,RAL6024 |

| Coating thickness | PE 16-18 microns | PE 16-18 microns |

| Surface | Plain coil | Triangle, circle, or rounded quadrilateral |

Printing

UV printing

When making aluminum plates with UV technology, the surface of the aluminum plate should be treated first. Then the paint layer should be treated, and finally, UV treatment should be performed;

Sublimation

When making aluminum plates with sublimation technology, the printing content needs to be prepared well and then directly transferred to the aluminum sublimation sheet.

What’s the difference between a UV printing aluminum sheet and an aluminum sublimation sheet?

Technology : Sublimation<UV printing;

Surface brightness: Sublimation>UV printing;

Water resistance test:Sublimation>UV printing;

Cost: Sublimation<UV printing;

Usage: Sublimation>UV printing;

Advertisement

In advertisements, aluminum channel letter coils are mostly applied in shop signs. Channel letter coils are aluminum strips used in the construction of three-dimensional channel letter signs: Flat, Triangular folded edge, and Flat folded edge.

| Alloy | 1050/1060 H14/H24 |

| Specification | 0.6 mm/0.8 mm/1.0.mm |

| Width | 60 mm/80 mm |

| Length | 50 m / 100 m |

| Coating | PE |

| Coating thickness | 16-18 microns |

3C Electrical appliances

We now supply more 1.5 mm PE coating 1060 aluminum coil for electrical appliances, 0.75 mm white coated aluminum sheet for refrigerator back panel.

1060 coated aluminum conclusion

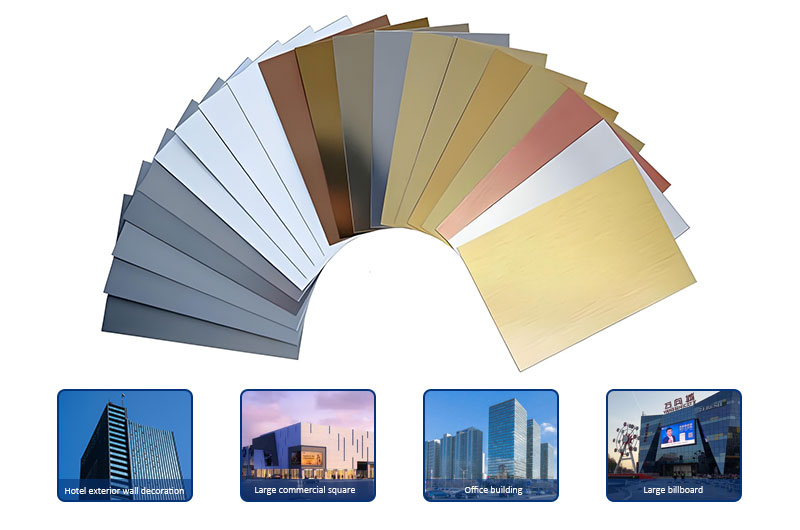

From the below application and analysis, we can see most paints for 1060 coated aluminum are PE paints. It is an anti-UV coating, especially suitable for interior decoration and advertising boards. Compared with PE paints, PVDF is another common paint. PVDF coating thickness is more than 25 microns, which is applied in high-demand industries, such as exterior buildings, curtain walls, and so on.

In conclusion, 1060 is a key in the alloy, with excellent price and suitable for most fields.

1060 is the most commonly used alloy, the production process is relatively simple, the technology is relatively mature, and the price has a huge advantage over other high-end alloy aluminum plates.

1060-coated aluminum has good elongation and tensile strength, which can fully meet the conventional processing requirements.PE paint is the king of cost-effectiveness among paints and has a long warranty period.

In summary, 1060 PE coated aluminum is the first choice for most indoor projects.