Advantage of 5052 Coated Aluminum Coil

- Corrosion resistance

- Decorative

- High strength

- Lightweight

- Form-ability

- Food safety

Product Parameters

Specification

| Item | Alloy | Temper | Coating Thickness | Base aluminum size | Capacity/month |

| Coated aluminum coil | 5052 |

H24,

H26 or as per customer's

requests |

As

per customer's

requests |

0.25-5 mm x30-1800 mmxC | 1500Tons |

Performance

| Alloy | Temper | Thickness/mm | Tensile Strength Rm/MPa | Tensile Strength/MPa | Elongation% |

| 5052 | H36, H46 | >0.220-0.300 | 255~305 | ≥200 | ≥2 |

| >0.300 -0.500 | 255~305 | ≥200 | ≥3 | ||

| H18, H38, H48 | >0.220 -0.300 | ≥270 | ≥210 | ≥2 | |

| >0.300-0.500 | ≥270 | ≥210 | ≥3 | ||

| H19, H39,H49 | >0.220 -0.300 | 290 | ≥220 | ≥2 | |

| >0.300-0.500 | ≥290 | ≥220 | ≥3 |

Chemical composition

| Si | Cu | Mg | Zn | Mn | Cr | Fe | Other | AI |

| ≤0.25 | ≤0.10 | 2.2~2.8 | ≤0.10 | ≤0.10 | 0.15~0.35 | ≤0.40 | ≤0.15 | Rem |

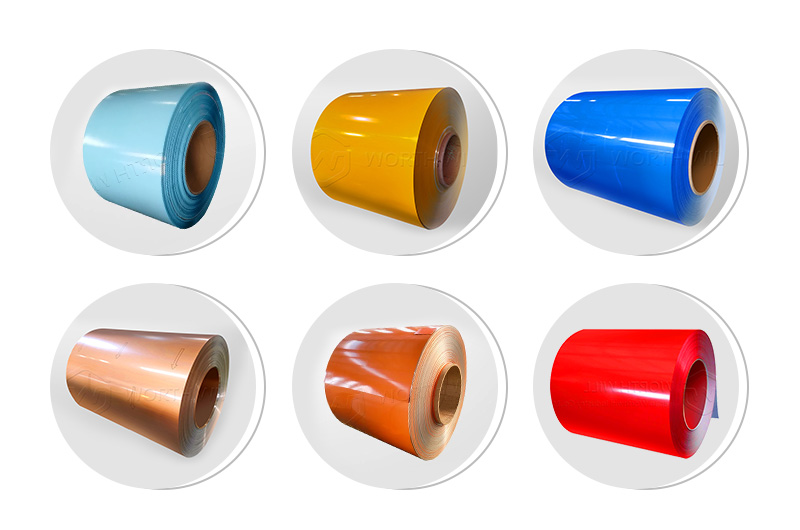

Color chart

Coating Type

PVDF paint

The stability and firmness of the chemical structure of PVDF color-coated aluminum coils make the physical properties of fluorocarbon coatings different from those of general coatings.

In addition to excellent mechanical properties such as wear resistance and impact resistance, it also shows long-term anti-fading and anti-ultraviolet properties, especially in harsh climates and environments.

After high-temperature baking to form a film, the molecular structure of the coating is compact and has super weather resistance.

PE paint

PE color-coated aluminum sheet is more economical than PVDF type. Its surface polyester coating is formed by multiple baking and has good protection and decorative properties. The coating can prevent erosion by ultraviolet rays, wind and rain, frost and snow, and corrosive gases, and is suitable for interior decoration and advertising board purposes.

HDP paint

High-durability polyester uses high molecular weight resin and inorganic ceramic pigments, and has the characteristics of strong stability, not easy to fade, UV resistance, good paint film adhesion, and long-lasting color. It is suitable for building facades, interior decoration, electrical appliances and furniture decoration, and has broad market prospects.

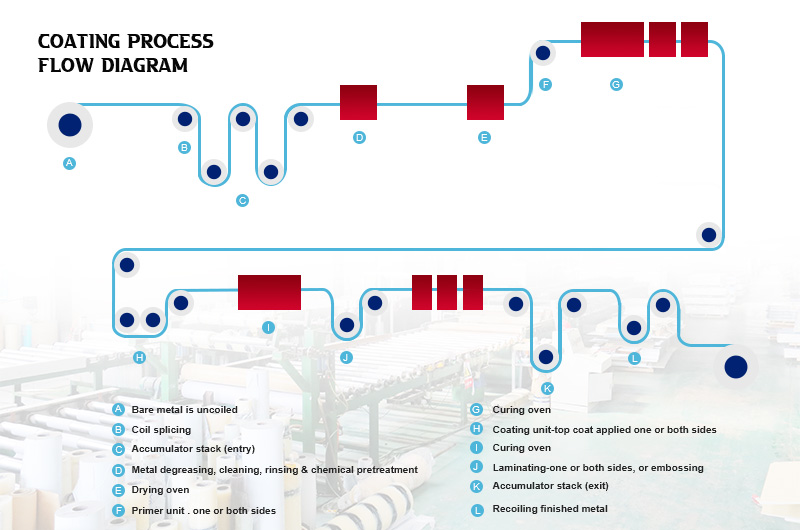

Processing Line

Application of 5052 Coated Aluminum Coil

Aerospace

5052 aluminum coil has become one of the preferred materials due to its light weight and high strength. It is used to manufacture key parts such as aircraft structural parts and engine components, which not only reduces the overall weight but also improves the strength and durability of the structure.

Automotive

5052 aluminum coils can significantly reduce the weight of the car body while maintaining sufficient load-bearing capacity and stability. In addition, the material can also be used to produce automotive cooling system components, such as radiators and water tank frames, to improve cooling efficiency and service life.

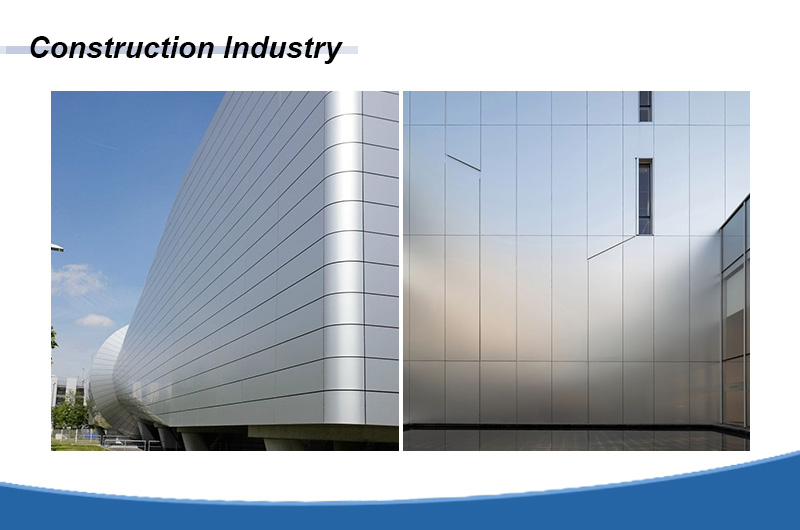

Construction Industry

Due to its outstanding high durability and corrosion resistance, it is very suitable for use as a building exterior decoration material or building structure support material. For example, the exterior curtain walls of some modern high-rise buildings are made of high-quality 5052 aluminum, which is both beautiful and practical.

Industrial

5052 coated aluminum coil is also used in various industrial applications such as storage tanks, pipes, and chemical equipment.

Marine Industry

5052 coated aluminum coil is highly resistant to salt water, making it an ideal material for manufacturing ships, containers, and other marine applications.

Packaging Materials

5052 coated aluminum coil is mainly used in the packaging field, for packaging of food, beverages, medicines and other products. Aluminum coil has moisture-proof, oxygen-proof, corrosion-resistant properties, etc., which can ensure the quality and safety of packaged products. For example, aluminum coil cans (suitable for beer, carbonated beverages, etc.).

Package&Shipping

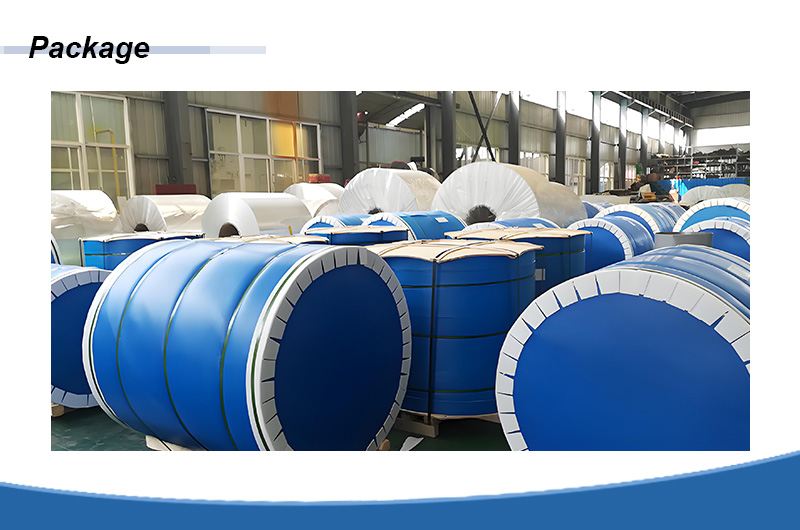

Package

Packaging of color coated aluminum coils usually includes moisture-proof inner packaging (such as plastic film or moisture-proof paper), protective materials (such as foam or non-woven fabrics), and the outer layer is fixed with fumigated wooden boxes or wooden pallets and reinforced with metal belts. Both sides are equipped with cardboard or metal guards to protect the edges, and the outer layer is wrapped with waterproof materials to prevent moisture during transportation.

The packaging is marked with product specifications, weight and manufacturer information, and can be customized according to customer needs to ensure that the aluminum coils are safe and intact during transportation and storage.

Shipping

Aluminum coils are shipped by truck, rail or sea, depending on the customer's preference. We can also provide international freight forwarding, with rich experience and long-term cooperation, which can be provided to customers for reference.

Technical Support and Services

- Technical advice on product selection and application

- Testing and inspection services to ensure product quality

- Technical guidance and support on product installation, use and maintenance

- Provide professional freight forwarding services, customers can choose according to their needs

In conclusion, 5052 color-coated aluminum coil is a highly durable and versatile product suitable for a wide range of applications. Its corrosion resistance and beautiful surface make it an excellent choice for buildings and other structures in coastal areas or harsh environments. Its mach-inability and form-ability also make it easy to process and form, ensuring your project looks perfect.

Henan WORTHWILL Industry Company, Professional 5052 color-coated aluminum coil manufacturer, meet your customized needs, welcome to inquire!