Coated aluminum is the process of coloring the surface of aluminum plates or coils with a coating. Common ones include PE & PVDF coated aluminum. They are widely used in aluminum veneers, aluminum honeycomb panels, aluminum ceilings, roof surfaces, cans, etc.

Specifications and performance of PE coated aluminum

Solid/Metallic Specification

| Item | Alloy | Temper | Coating Thickness | Aluminum sheet size | Capacity/month |

| Solid/Metallic | 1.3.5 Series or customize | H24,H26 or customize | About 16-35μm or customize | 0.25-5 mm x30-1800 mmxC | 1500 Tons/Month |

Wooden grain/Stone grain Specification

| Item | Alloy | Temper | Coating Thickness | Aluminum sheet size | Capacity/month |

| Wooden grain/Stone grain | 1060/1100/3003/3004 or customize | H24,H26 or customize | 35μm or customize | 0.25-1.35 mm x30-1350 mmxC | 500 Tons/Month |

Mirror coated Specification

| Item | Alloy | Temper | Coating Thickness | Aluminum sheet size | Capacity/month |

| Mirror coated | 1050/1060/1100or customize | H24 or customize | Customize | 0.25-1.35 mm x30-1350 mmxC | 500 Tons/Month |

Brushed coated Specification

| Item | Alloy | Temper | Coating Thickness | Aluminum sheet size | Capacity/month |

| Brushed coated | 1050/1060/1100or customize | H24 or customize | Customize | 0.45-1.35 mm x900-1350 mmxC | 500 Tons/Month |

Performance

| ltem | Test ltem | >Standard | National standard | Test Result |

| 1 | Color Difference | >ECCA T3 | △E≤2.0 | △E≤1.5 |

| 2 | Gloss Difference | >ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | >ECCA T1 | Min 14μm | ≥16μm |

| 4 | Pencil Hardness | >ASTM D3363 | ≥HB | HB |

| 5 | T-bend | >ASTM D4145 | ≤3T | ≤2T |

| 6 | Adhesion | >ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | >ASTM D2794 | =20kg.cm | ≥20kg.cm |

| 8 | Boiling water Resistance | >GB/T17748 | 2h no change | 2h no change |

| 9 | Solvent Resistance | >ASTM D2248 | 200 times paint remaining |

200

times paint

remaining |

| 10 | Salt Resistance | >ASTM B117 | 720 hrs≤grade 1 | 720hrs≤grade 1 |

| 11 | Dirt Resistance | >GB/T9780 | ≤5% | <5% |

| 12 | Color retaining | GB/T16259 | 600hrs△E≤2.0 | △E≤2.0 |

| 13 | Gloss weaken Level | 600hrs≤grade 2 | 600hrs≤grade 2 | Gloss weaken Leve |

| 14 | Chalking | 600hrs No Change | No Change | / |

Advantage of PE coated aluminum

- Paint wood grain and stone grain, with realistic physical texture and fresh natural beauty.

- Lightweight.Aluminum has low density and is a lightweight metal.

- Good weather resistance: The paint pattern formed by high temperature baking has long-lasting gloss, stable color, almost no color difference, and a 10-year warranty.

- Environmental protection. Salt-resistant, alkali-resistant, acid rain-resistant, rust-resistant, and flame-retardant.

- Good performance. The product has the bending and folding strength required for decorative panels, and can remain unchanged from bending, deformation or expansion in the changing climate of four seasons.

- Easy to maintain. The surface of the aluminum plate is easy to clean, just wipe it gently.

- High cost performance. Polyester is cheaper than fluorocarbon and has high cost performance.

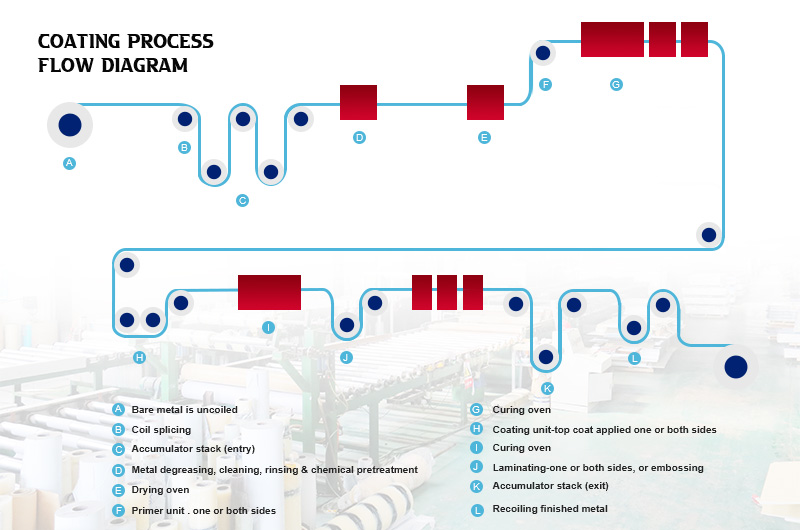

PE Coated Aluminum Production

Processing line

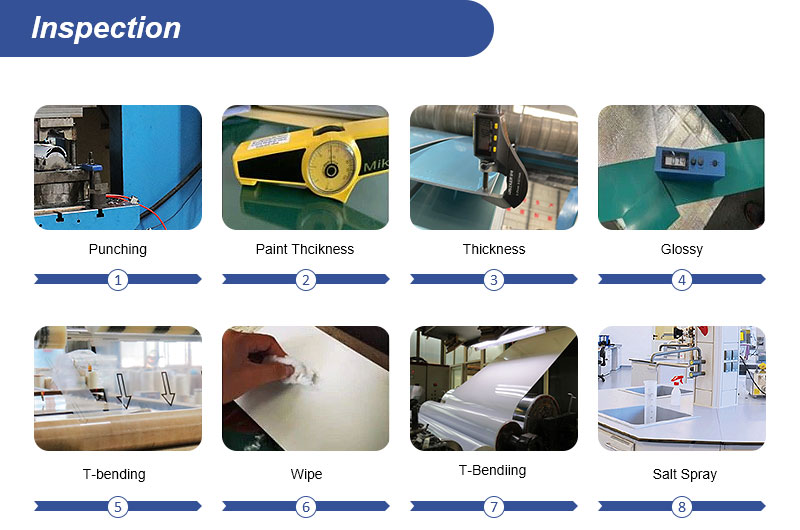

Inspection

Application

Building

| Name | Color | Alloy | Temper | Thickness | Size |

| Gutter | White | 1060 | H14/H24 | 0.6-0.8mm | According to customer requirements |

| Roofing | Traffic red/blue | 1060/3003 | H24 | 1-2mm | According to customer requirements |

| Ceiling | White | 1060 | H14/H24 | 0.5-0.7mm | 640*640mm |

| Facades | Monarch Gold, Monument Black, Flash Silver, etc. | 3003/3105/5052/5005 | H14/H24 | 2.85 mm / 3 mm | 1000*2000/ 1220*2440/1220*3050 |

Printing

- UV Digital printing

- Aluminum sublimation sheet

Tank car Body

- Caravan car body material

- License Plate Material

Advertising

Aluminum channel letter

Electronics

- Mobile phone case &Computer host

- Electrical back panel

Why Choose us

Henan Worthwill industry Co.,Ltd is the only international department of Henan jurun NewMaterial Co.,Ltd, the factory is located in Huiguo Town Industrial Park, Gongyi City, Zhengzhou City, Henan Province, with convenient transportation. Specializing in the production of 1, 3, 5, 6 and 8 series alloy aluminum painted coils/sheets, aluminum solid/metal cladding sheets and other aluminum alloy products. We are the only company in the province that can produce roller coating products with a maximum thickness of 5.0mm and a width of 1800mm. Our factory has 6 roller coating and spraying production lines with thickness from 0.05mm -5.0mm and a maximum width of 1800mm.

Welcome to inquire!

Package

- Divided into“eyes to wall”&“eyes to sky”

- The inner layer is waterproof kraft paper packaging with desiccant

- The outer layer is plastic waterproof packaging

- Use fumigated wooden pallets and steel belts to further enhance the firmness and stability of the packaging and effectively protect the safety of the product