PVDF Coated Aluminum

Worthwill's PVDF coated aluminum offers customizable colors and a wide range of products, including PVDF aluminum sheets, coils, composite panels, and extrusion profiles, providing perfect solutions for all your needs.

- Product type:

- Coil, Sheet, Composite Panel.

- Alloy:

- 1060, 3003, 3004, 3005, 3105, 5005, 5052 etc.

- Temper:

- H12, H14, H16, H18,H22, H24, H26, H42, H44etc.

- Thickness:

- 0.1mm - 6.0 mm (roller) or customized (powder coating).

- Width:

- 30mm – 2, 200mm .

- Coating Type:

- PVDF.

- Coating Thickness:

- min 25 μm.

- Colors:

- Regal blue, regal red, terra cotta, classic green, matte black, sandstone almond, regal white, medium bronze, mansard brown, etc.

PVDF Aluminum Overview

What is PVDF Coated Aluminum?

PVDF aluminum is an aluminum material coated with polyvinylidene fluoride (PVDF) resin, known for its excellent weather resistance, corrosion protection, and color retention, making it ideal for architectural and aerospace applications.

PVDF Coating on Aluminum

Polyvinylidene Fluoride (PVDF coating), part of the fluoropolymer family, is a resin-based coating system designed for metal surfaces. It delivers exceptional weather resistance, chemical resistance, and UV stability.

Features and Benefits of PVDF Aluminum

- Chemical Stability: Non-reactive, resistant to acids, solvents, and chemical corrosion.

- Weather Resistance: UV-resistant, salt spray-resistant, and humidity-resistant (tested for 4,000 hours), with color stability for up to 20 years.

- Fire Safety: Self-extinguishing, low smoke emission, compliant with building fire codes.

- Mechanical Performance: Grade 0 adhesion (no peeling), high impact resistance, hardness ≥1H (pencil hardness).

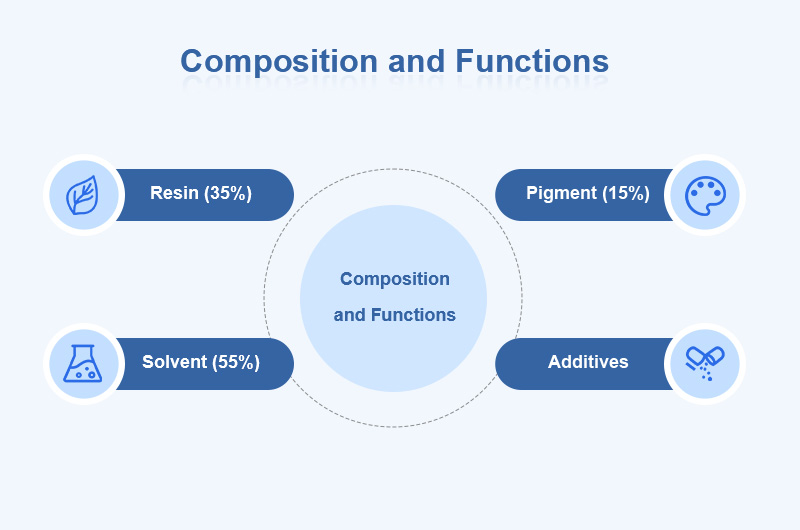

Composition and Functions

- Chemical Stability: Resin (35%): Determines durability (e.g., PVDF, FEVE, SMP).

- Solvent (55%): Acts as a carrier, ensuring uniform coating application and evaporation during curing.

-

Pigment (15%): Provides color and chemical resistance. Categories:

- Inorganic Pigments: Stable, lightfast, but limited to earthy tones.

- Organic Pigments: Vibrant but less weather-resistant and costly.

- Pearlescent/Metallic Pigments: Add shimmer and dynamic color shifts.

- Additives: Optimize flow, curing speed, hardness, etc.

Paint Brands

PPG, AKZONOBEL, ASIA, 3 TREES, JOTUN, KFCC, KGE, SKK, First NMT, HUARUN

PVDF Coated Aluminum

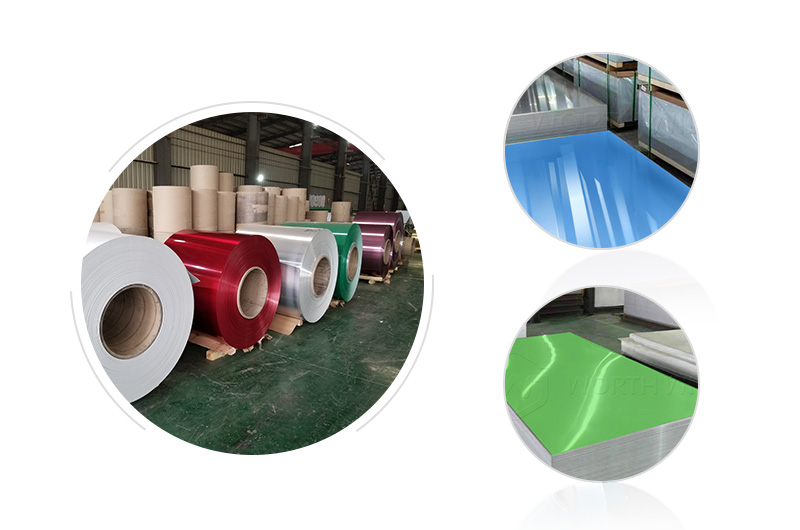

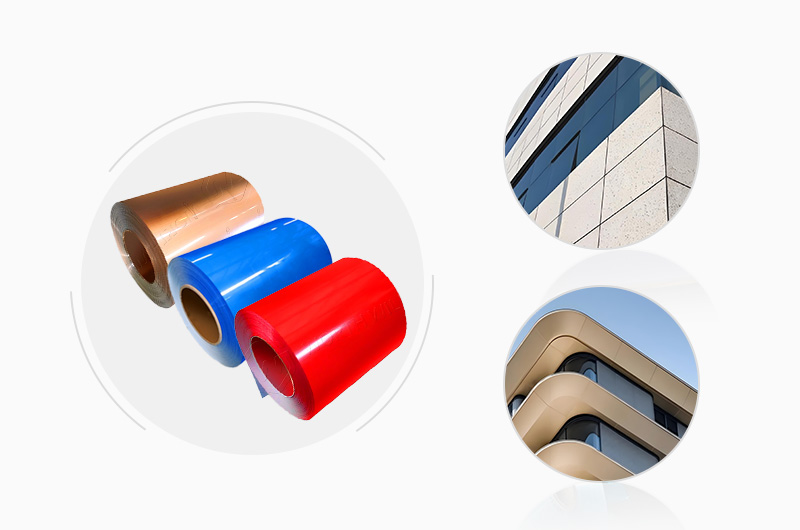

PVDF Coated Aluminum Coil and Sheet

- Alloy: 1060, 3003, 3004, 3005, 3105, 5005, 5052.

- Coating Thickness: more than 25 μm.

- Sheet Thickness: 0.6mm – 5.0mm (coil) or custom (powder).

- Width: 30mm – 2,200mm (customizable).

- Common Colors: Regal blue, regal red, terra cotta, classic green, matte black, sandstone almond, regal white, medium bronze, mansard brown.

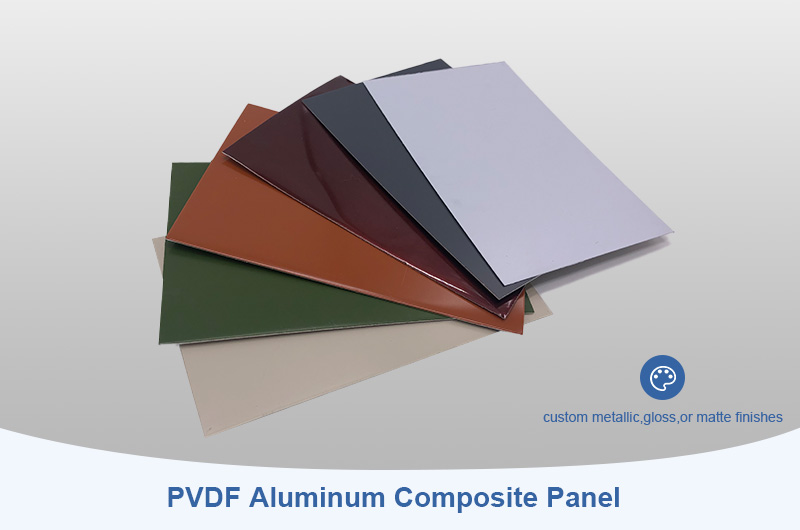

PVDF Aluminum Composite Panel

- Structure: Two aluminum sheets sandwiching a polyethylene core, with PVDF Kynar paint on the front.

- Panel Thickness: 3mm – 6mm (recommended 4mm); aluminum skin 0.21mm – 0.50mm (recommended 0.30mm/0.40mm).

- Standard Sizes: 1220mm × 2440mm, 1500mm × 3050mm (customizable).

- Colors: 45 standard factory colors; custom metallic, gloss, or matte finishes.

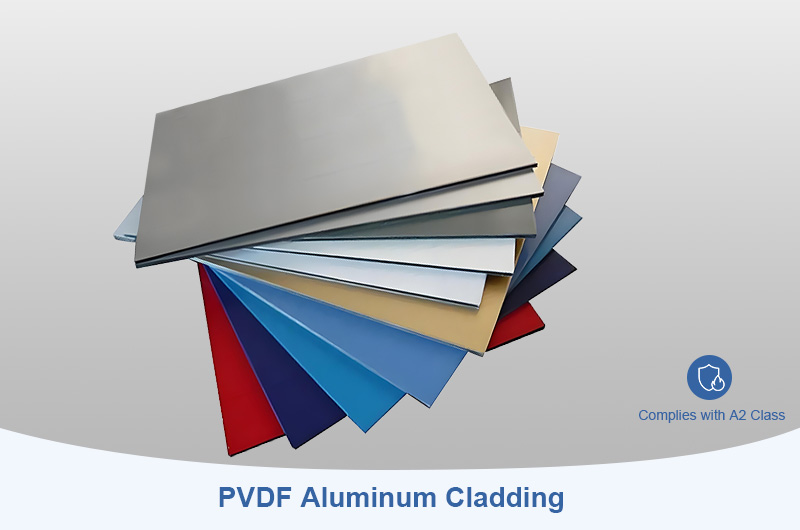

PVDF Aluminum Cladding

- Thickness: Aluminum skin 0.12mm – 0.50mm; panel total 2mm – 6mm.

- Dimensions: Width 1,000mm – 2,000mm (max), length up to 6,500mm (standard 1220mm×2440mm).

- Colors: Available in RAL color system or custom colors (e.g., Metallic Silver, Champagne Gold, Pure White).

- Fire Rating: Complies with A2 Class (Chinese National Standard GB 8624-2006, non-combustible).

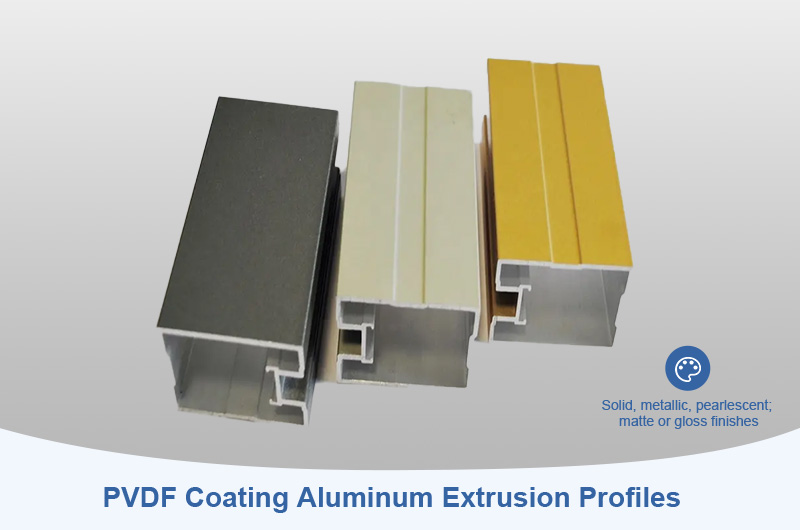

PVDF Coated Aluminum Extrusion Profiles

-

Size(mm): Coating Thickness:

- 2-layer (primer + topcoat): more than 25μm.

- 3-layer (primer + color + clear):o more than 34μm.

- Thickness: Salt Spray Resistance: more than 4,000 hours.

- Alu Skin Thickness: Adhesion: Grade 0 (no peeling).

- Coating: Color Options: Solid, metallic, pearlescent; matte or gloss finishes.

Customizable PVDF Color Chart

PVDF finished aluminum sheets and coil from Worthwill offer a wide range of coatings color including solid colors, metallic colors,such as regal white,pearl gray, surrey beige, etc, and color is customizable.

Regal White

Reflective White

Warm White

Pearl Gray

Desert Sand

Surrey Beige

Slate Gray

Royal Blue

Terra Cotta

Cypress Green

Dark Bronze

Brite Red

Charcoal

Midnight Black

Galvalume

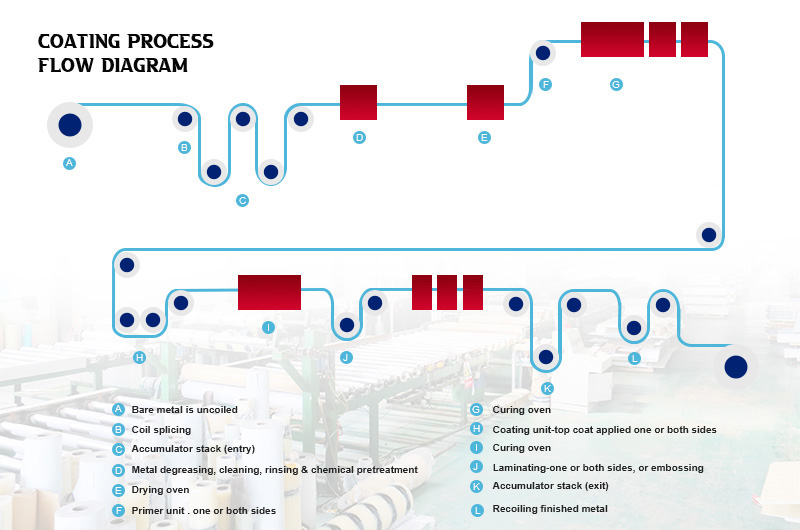

The Coating Process of PVDF Coated Aluminum

Worthwill operates two production lines: roll coating (for flat surfaces like coils/sheets ≤5mm) and powder coating (for complex shapes, small batches).

- Surface Prep: Degreasing, acid cleaning, and chemical conversion treatment.

- Primer Application: Enhances adhesion and stabilizes the substrate.

- Topcoat Application: PVDF resin + pigments for wear-resistant protection (thickest layer).

- Clear Coat (Optional): Prevents fading and boosts weather resistance.

- Curing: High-temperature baking (230–250°C, 10–15 mins) or room-temperature curing.

PVDF vs. Other Resin-Based Coatings

| Resin Type | Characteristics | Applications |

|---|---|---|

| SMP | Abrasion-resistant, cost-effective | Industrial/agricultural equipment |

| Polyester | Versatile, wide color range | Appliances, gutters |

| FEVE | High gloss, PVDF-level weather resistance (higher cost) | Premium decoration |

| PVC | Low-cost, poor weather resistance | Non-exposed surfaces |

Testing Standards & Results

Durability

- Salt Spray: Passes 4,000-hour neutral salt spray test (blistering rating < 2S3, no defects).

- Humidity Resistance: Passes 4,000-hour humidity aging; no blistering/cracking after 1,000 hours.

- Weathering: 2,000 hours of UVA-340 UV exposure (ASTM D4214); chalking ≤1, no blistering/cracking.

Mechanical Performance

- Hardness: Pencil hardness ≥2H.

- Impact Resistance: 9J reverse impact (no cracking/peeling).

- Flexibility: 3T bend test (no peeling).

- Bending Strength: 4,030 kg/mm² (ASTM D790).

Protective Performance

- Adhesion: Cross-cut test (no peeling).

- Scratch Resistance: 1,800g probe scratch (no damage).

- Boiling Water Resistance:2 hours in 100°C water (no fading/cracking).

Other

- Fire Rating: A2 (GB 8624-2006).

- Coating Thickness: 27μm (meets ≥25μm requirement).

PVDF Coating vs. Powder Coating

| Factor | PVDF Coating | Powder Coating |

|---|---|---|

| Weather Resistance | 20+ years, extreme UV resistance | 7–8 years, prone to fading |

| Eco-Friendliness | Zero VOC | Recyclable powder, high curing energy |

| Cost | High ($15–30/m²) | Low ($5–10/m²) |

| Applications | Outdoor exposure (façades, roofs) | Indoor decor, short-term projects |

PVDF Coating vs. PE/HDPE Coatings

| Property | PVDF Coating | PE Coating | HDPE Coating |

|---|---|---|---|

| Chemical Resistance | Excellent | Moderate | High |

| Weatherability | Superior | Moderate | Good |

| Mechanical Strength | High | Flexible | High |

| Flexibility | Moderate | High | Low |

| Cost | High | Low | Moderate |

| Applications | Architecture, industrial, automotive | Food packaging, medical | Marine, construction |

Applications & Recommendations

PVDF coated aluminum is ideal for façades, composite panels, chemical processing equipment, and roofing.

-

Recommended Uses:

- Roofing/cladding, indoor décor.

- Chemical plants, industrial roofs (corrosion resistance).

- Budget Alternatives: Powder coating for indoor/short-term projects.

Why Choose Worthwill’s PVDF Coated Aluminum?

Worthwill's PVDF coated aluminum sheet and coil, with the PVDF coating's weather resistance, corrosion resistance, chemical resistance, color retention and anti - pollution properties, as well as the aluminum alloy's lightweight, high strength and good thermal conductivity, enhances corrosion resistance and durability while maintaining its original physical properties.

- Certified Quality: High-quality resin with stable performance.

- Premium Materials: PPG, Nippon, and other global paint suppliers.

- Sustainability: Reduces building energy consumption; meets green standards.

- Customization: Tailored sizes, colors, finishes.

- Warranty: 20-year PVDF coating warranty; 10-year PE core warranty.