Wood Grain Aluminum

Wood grain aluminum sheets from Worthwill offer a wide range of wood grain patterns, including common textures such as walnut, beech, oak, elm, teak, ebony, rosewood, and cedar, supporting PE, PVDF coating, widely used in construction industry, home decoration etc.

- Alloy:

- 1050, 1060, 3003, 3004, 3005, 3105, 5005, 5052, 5454, etc.

- Product type:

- Coil, sheet, panels.

- Temper:

- H16, H24, H26, H42, etc.

- Thickness:

- 0.2mm - 6.00mm.

- Width:

- 20mm-1850mm.

- Coating Type:

- PE, PVDF.

- Wood grain texture:

- Walnut, beech, oak, elm, teak, ebony, rosewood, and cedar, etc.

- Standards:

- Compliance with ISO, ASTM, AAMA, GB/T, and EN standards.

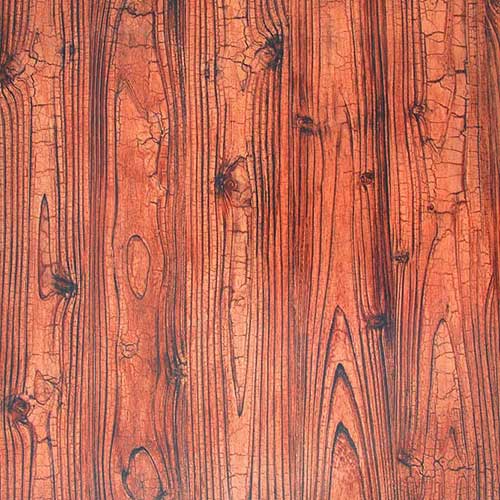

What is the wood grain aluminum?

wood grain aluminum, also known as timber look aluminum, a metal decorative material that replicates wood textures and colors on aluminum surfaces through pre-rolled coating, thermal transfer, or similar techniques.

Combining the durability of metal with the aesthetics of wood, it serves as an eco-friendly alternative to timber for architectural facades, cladding, siding, ceilings, and interior/exterior decor.

Specifications

Besides the wood grain transfer workshop, Worthwill also have our own secondary processing workshop, capable of edging, bending, and drilling.

Worthwill can customize various types of wood grain aluminum products according to your needs, whether it is trim coil, sheet, siding, or section / slats. Here are the regular specifications for wood grain aluminum.

- Alloy: 1050, 1060, 3003, 3004, 3005, 3105, 5005, 5052, 5454, etc.

- Temper: H16, H24, H26, H42, etc.

- Thickness: 0.6mm – 6 mm.

- Width: 20mm – 1850 mm.

- Length: Customizable.

- Coating Type: PE/PVDF.

- Coating Thickness: Greater than 25 μm.

- Paint Brands: PPG, Beckers, etc.

- Wood Grain Texture: Scratch-resistant wood grain and 3D textured wood grain as below.

- Thickness: 0.2mm - 1.0mm.

- Width: 20mm - 1500mmmm.

- Core Diameter 150mm,405mm, 505mm, 508mm, 510mm.

- Thickness: 0.6mm – 6 mm.

- Width: 800mm - 1850mm.

- Length: Customizable.

Wood grain texture Worthwill support

Wood grain aluminum sheets from Worthwill offer a wide range of wood grain patterns, including common textures such as walnut, beech, oak, elm, teak, ebony, rosewood, and cedar, and also support customized processing.

Scratch resistant wood texture

Antique Pine

Antique spliced

Black pine

Camphorwood

Deadwood

Indian ancient pine

Light red camphor

Light teak

Light yellow walnut

Maple

Olive

Pine

Red pine

Rosewood

Walnut

Willow

Seamless 4K wood texture

Ancient landscape pine

Antique chestnut

Antique elm

Antique oak

Antique olive

Antique poplar

Antique birch

Antique birch

Antique ebony

Antique ginkgo

Antique padauk

Antique poplar

Black locust

popular grain

White wood

Aluminum alloy selection

Comparison of alloy designations for wooden look aluminum coil and sheet.

| Alloy | Chinese Standard | American Standard | European Standard |

| 1000 Series | 1050 | – | – |

| 1050A | – | EN AW-1050A | |

| 1100 | 1100 | – | |

| 3000 Series | 3003 | 3003 | EN AW-3003 |

| 3105 | 3105 | EN AW-3105 | |

| 5000 Series | 5005 | 5005 | EN AW-5005 |

| 5052 | 5052 | EN AW-5052 |

Production techniques

Different coating techniques are chosen based on project needs: roll coating for large facades, powder coating or water transfer for complex shapes, thermal transfer for high-detail small areas, thermal transfer combined with PVDF for maximum durability, and roll coating again for budget-friendly solutions.

Thermal transfer

- Process: High-temperature transfer of wood patterns onto aluminum.

- Pros: High realism, customizable designs.

- Cons: Discontinuous texture, moderate durability (8–15 years).

- Applications: Small-scale decor, personalized projects.

- Cost: Medium-high. sing.

Powder Coating

- Process: Wood-grain effect using specialized powders on irregular profiles.

- Pros: Adaptable to complex shapes, easy repairs.

- Cons: Uneven texture, lower durability (8–15 years).

- Applications: Curved surfaces, double-curvature designs.

- Cost: High.

Roll Coating

- Process: Mechanical coating for continuous wood patterns.

- Pros: High efficiency, durability (15–25 years).

- Cons: Limited customization.

- Applications: Large-scale facades, exterior walls.

- Cost: Medium-low.

Film Lamination

- Process: Adhesive-backed wood-grain films.

- Pros: High decorative appeal.

- Cons: Low durability (5–10 years), indoor use only.

- Applications: Indoor decor.

- Cost: Low.

Combined Processes

- Thermal Transfer + PVDF Powder Coating: Extreme weather resistance for premium facades.

- Roll Coating + Thermal Transfer: Balanced texture and durability for outdoor walls.

- Powder Coating + Thermal Transfer: High adhesion for complex shapes.

Application

Architecture

- ACP panels.

- Wood grain panels.

- Wood grain cladding.

- Wood grain siding.

- Wood grain section and slats.

Home decoration

- Doors.

- Windows.

- Furniture.

- Cabinets.

- Feature walls.

Commercial spaces

- Retail façades.

- Hotel interiors.

- Office lobbies.

- Store fronts.

Outdoor Facilities

- Garden furniture.

- Landscaping elements.

- Signage.

Advantages and Benefits

10–15 years of fade/weather resistance; recyclable, non-toxic.

Realistic wood patterns (walnut, oak, cedar, teak, etc.), customizable shapes/colors.

A1 fire rating (EN 13501-1/GB/T 8624).

Scratch-resistant, easy-to-clean surface.

Lightweight (8 kg/m² for 3.0mm), high strength (100–280 N/mm²), corrosion/insect/mold-resistant.

The size, shape, and color can be customized to meet personalized space design.

Quality control and testing

Compliance with ISO, ASTM, AAMA, GB/T, and EN standards. Key tests include:

| Test Item | Standard | Result |

| Salt Spray Resistance | ASTM B117 (4,000 hrs) | No corrosion |

| Color Retention | GB/T 16259 (4,000 hrs) | ΔE ≤3.0 |

| Adhesion | ASTM D3359 | Grade 0 |

| Hardness | / | more than 2H |

| Weathering | Florida exposure tests | Qualicoat Class 1 |

Market outlook

Timber-look aluminum is revolutionizing sustainable construction and interior design. Its durability, customization, and eco-friendliness outperform traditional wood, appealing to eco-conscious consumers and architects.

- Superior sustainability, aesthetics, and longevity.

- Seamless integration of natural visuals with modern functionality.

- Rising demand for green, low-maintenance solutions.

- The price for 2mm-thick wood-like aluminum sheets or coils ranges from $10/m² to $35 /m²(varies by quality/process).