What is lacquered aluminum?

Lacquered aluminum refers to a layer of varnish or colored paint applied to the aluminum surface.

This coating is usually low-viscosity and thin layer. After drying, it will form a hard protective layer that not only protects the aluminum surface from corrosion and wear, but also increases its gloss and beauty.

Features:

- Quick drying to form a hard and durable surface.

- Provides high gloss and smooth appearance.

- Strong corrosion resistance.

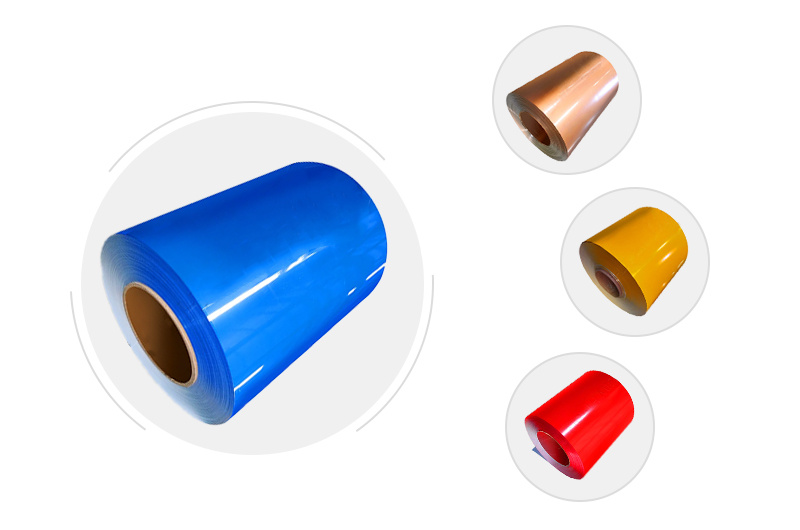

Worthwill's lacquered aluminum products

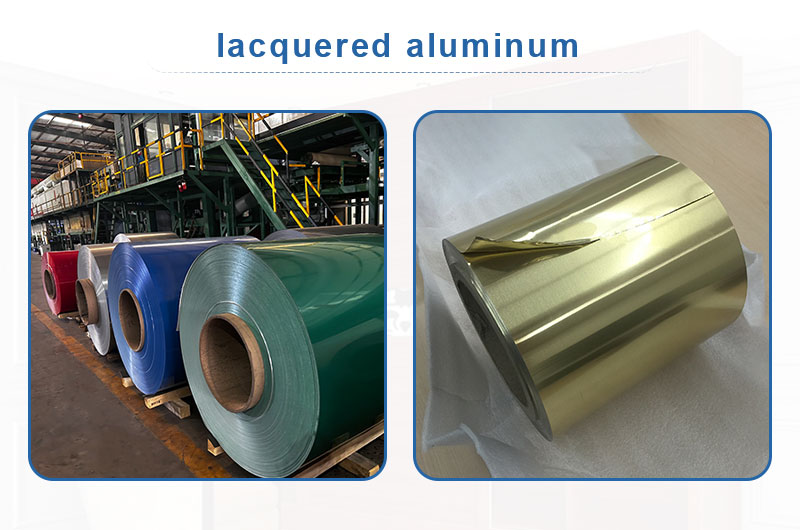

Worthwill has an advanced lacquered aluminum production line with integrated painting and drying, and the temperature in the furnace is stable and uniform.

Through continuous voltage control and closed-loop feedback technology, the voltage of the aluminum coil at the input and output ends of the production line is ensured to be consistent, thereby achieving:

- Consistent thickness of the entire coil.

- No wrinkles at thin thickness.

- Higher coating efficiency.

- No deformation and consistent color.

Worthwill's coating production line can coat both sides of the aluminum sheet and coil at the same time, thereby achieving:

- Improve process efficiency and shorten delivery time.

- More competitive price.

Worthwill's lacquered aluminum coating methods include spraying and roller coating. We support a variety of paint types, such as PE, PVDF, HDPE, etc.

If the spraying process is used, dull aluminum spray paint can also be used. Click to view detailed paint types.

In addition, Worthwill also supports a variety of lacquered aluminum surface treatments, as follows:

- Brushed.

- Embossing.

- Mirror.

Lacquered aluminum sheet and coil

Specifications:

Lacquered aluminum sheets are cut from aluminum coils to specific lengths, and the general specifications are as follows:

- Alloy: 1000, 3000, 5000 series.

- Temper: H12, H22, H24, H26, H42, H44, H46.

- Thickness: 0.18mm-3.0mm.

- Width: 100mm-1500mm.

- Coil ID: 508mm or 610mm.

- Single coil weight: 1.6 to 3 tons, maximum weight 6 tons.

Paint thickness:

Worthwill's coating line is equipped with continuous measuring equipment to ensure consistent paint thickness, and the paint thickness is as follows:

- Back coating: 3 - 12µm.

- Single coating: 4-20 µm.

- Double coating: 25-28 µm.

- Triple coating: 30-38 µm.

lacquered aluminum foil

Worthwill’s lacquered aluminum foil is coated on both sides with solvent or water-based primer, protective layer and thermal spray paint, and is widely used in food packaging and other fields.

Specifications:

- Alloy: 8011, 8079.

- Temper: O.

- Thickness: 0.008mm-0.2mm.

- Paint Thickness: 3-25μm.

- Width: 60mm and above.

- Roll ID: 75mm or 150mm.

- Paint Color: White, Gold or as per customer’s requirement.

Paint Thickness:

- Conventional Paint Thickness: 8-13 GSM.

- Gold/Yellow Coating: 5-6 g/m²for double-sided coating, 2-4 g/m² for single-sided coating.

Coating Type:

- Double-sided transparent epoxy varnish.

- One side transparent epoxy varnish, the other side color coating.

Uses of lacquered aluminum

Lacquered aluminum has a wide range of uses, including packaging industry, transportation industry, home appliance industry, home furnishing industry, insulation, ventilation system (HVAC), outdoor construction, etc.

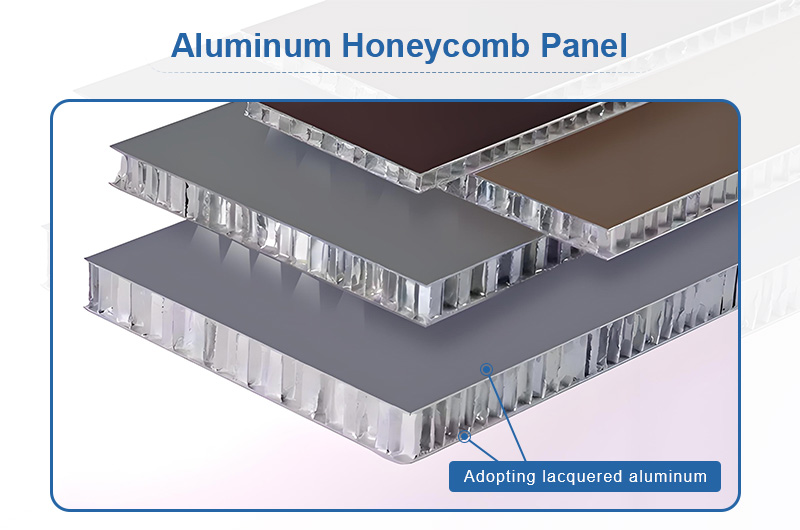

In addition, lacquered aluminum coils are often used to produce aluminum sandwich panels and composite panels, such as the top and bottom sheets of aluminum honeycomb panels, and the panels of aluminum-plastic composite panels.

The recommended alloys are EN AW 3105, EN AW 5005, and EN AW 8011A, which comply with European standard EN 573-3.

The following are two examples of the use of lacquered aluminum:

Lacquered aluminum in bottle caps

Worthwill's lacquered aluminum is formulated with special resins for strict sterilization processes in the pharmaceutical and cosmetic industries, ensuring the highest quality and hygiene standards and complying with European directives and FDA regulations for contact with food.

- Pharmaceutical industry: used for bottle caps, closures, and vials.

- Anti-theft closures: used in the pharmaceutical industry to ensure product safety.

- Cosmetic industry: used to produce various caps and containers.

Bottle caps are mostly made of lacquered aluminum 8011 aluminum alloy, with epoxy varnish on the back and polyester (PE) on the front. When the cap needs to be punched, alloy 8079 is recommended.

- Alloy: EN AW 8011A, EN AW 8079.

- Temper: O.

- Thickness: 0.018mm-0.4mm.

- Coating method: single-sided or double-sided coating.

- Color: colorless or colored coating.

Lacquered aluminum foil in easy-tear covers

The application of lacquered aluminum foil in easy-tear covers mainly includes: milk powder covers, instant coffee cup covers and other easy-tear covers.

- Alloy: 8011, 1235, 8079.

- Temper: O.

- Thickness: 0.025MM - 0.05MM.

- Width: 150mm - 1000mm.

The yogurt cover film is mainly made of composite materials, consisting of polyester/aluminum foil/heat sealing layer (PET/AL/PE·EVA).

Worthwill's lacquered aluminum foil is the perfect solution for aluminum foil for yogurt covers.

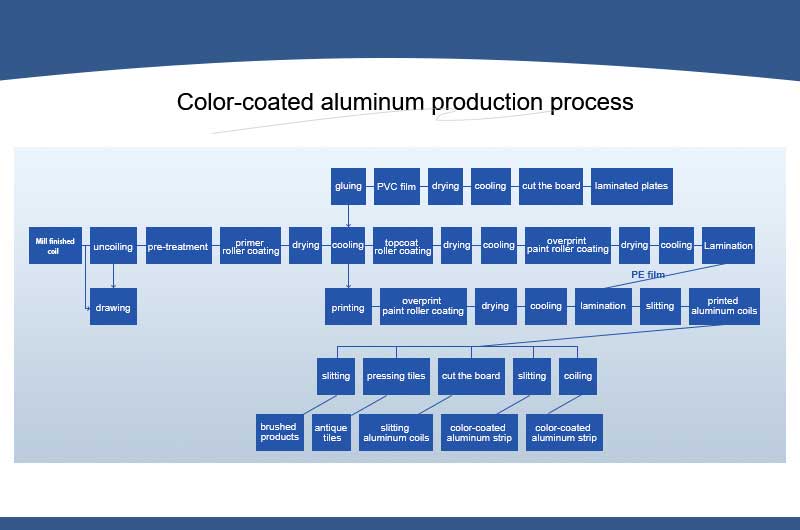

Lacquered aluminum process

Step 1: Pretreatment before color coating

- Hot water cleaning.

- Hot alkali degreasing.

- Passivation treatment.

Step 2: Roll coating (single coating)

- Primer roller coating.

- Drying.

- Cooling.

Step 3: Topcoat roller coating (double coating)

- Topcoat roller coating.

- Drying.

- Cooling.

Lacquered aluminum paint

Lacquer paint for aluminum has various types, including:

- Polyamide (PA).

- Polyurethane/polyamide (PUPA).

- Polyethylene (PE).

- High-density polyethylene (HDPE).

- Polyvinylidene fluoride (PVDF).

- Acrylic Paint.

- Epoxy Paint.

- Oil-Based Paint.

- Powder Coating.

In addition, we can also produce lacquered aluminum with hydrophobic coating and hydrophilic coating.

Key points for choosing aluminum spray paint

When choosing paint for aluminum, the following key features need to be considered:

- Good adhesion.

- Resistance to abrasion and atmospheric factors.

- Flexibility.

- UV resistance.

- Chemical resistance.

- Heat resistance.

- Compatibility and application.

- Fast drying and curing.

- Clear or pigmented formula.

Our services

Aluminum coil cutting

According to the customer's process requirements, we process aluminum coils and cut them into precise sizes, from 700 mm to a maximum sheet width of 1500 mm. Our continuous cutting process guarantees perfect parallelism and minimal material waste.

Customized service

We can customize various specifications of sprayed aluminum for your project. There are hundreds of colors to choose from. You just need to provide color cards or samples, and we will contribute to your next successful project.